5

4) Allow for control valves in suction and discharge piping. (Essential if pump

is mounted below water level).

5) Have adequate floor drainage to prevent pump being immersed in water due

to flooding.

6) Protect from excess moisture, vermin, dust and weather.

7) Allow access for servicing pump and piping.

8) To provide adequate ventilation keep rear of motor clear (100mm Min)

9) Do not use electrical extension cords/leads.

NEVER run pump dry! Running pump dry may damage

seals, causing leakage and flooding! Fill pump with

water before starting motor.

Electrical Operation

240 volt single phase are supplied as standard with built-

in thermal overload protection and are designed to plug

direct into a 10 amp domestic power supply socket to

local electrical authority specifications. Onga recom-

mends that an earth leakage/residual current protection

device must be fitted to all installations.

OPERATION

INSTALLATION (Continued)

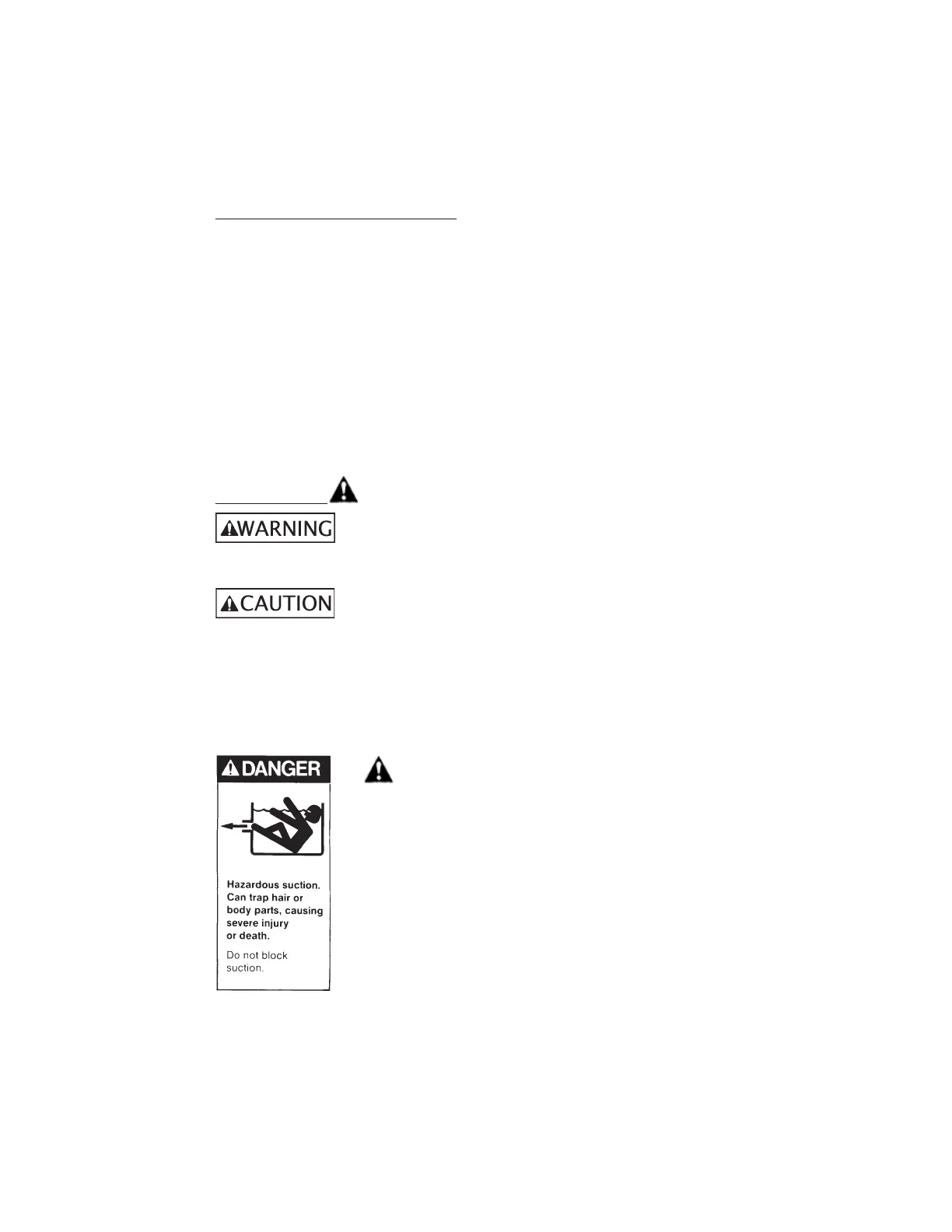

Do not block pump suction! To do so with body

may cause severe or fatal injury. Small children

using pool must ALWAYS have close adult

supervision!

Loading...

Loading...