BWS350 System Installation, Operation & Maintenance 3

The BWS350 Advanced Membrane Separation System is designed specically for users that desire the ability to customize

the TDS (Total Dissolved Solids) level or “Mineral Content” of the treated water. The BWS350 utilizes a precision multi-turn

Blending Valve to accomplish this with great accuracy. This system design maximizes the ability to accurately blend a calcu-

lated percentage of the ltered water with the product water exiting the AMS-QT Membrane, providing an Optimized Water to

your equipment with the characteristics that you desire.

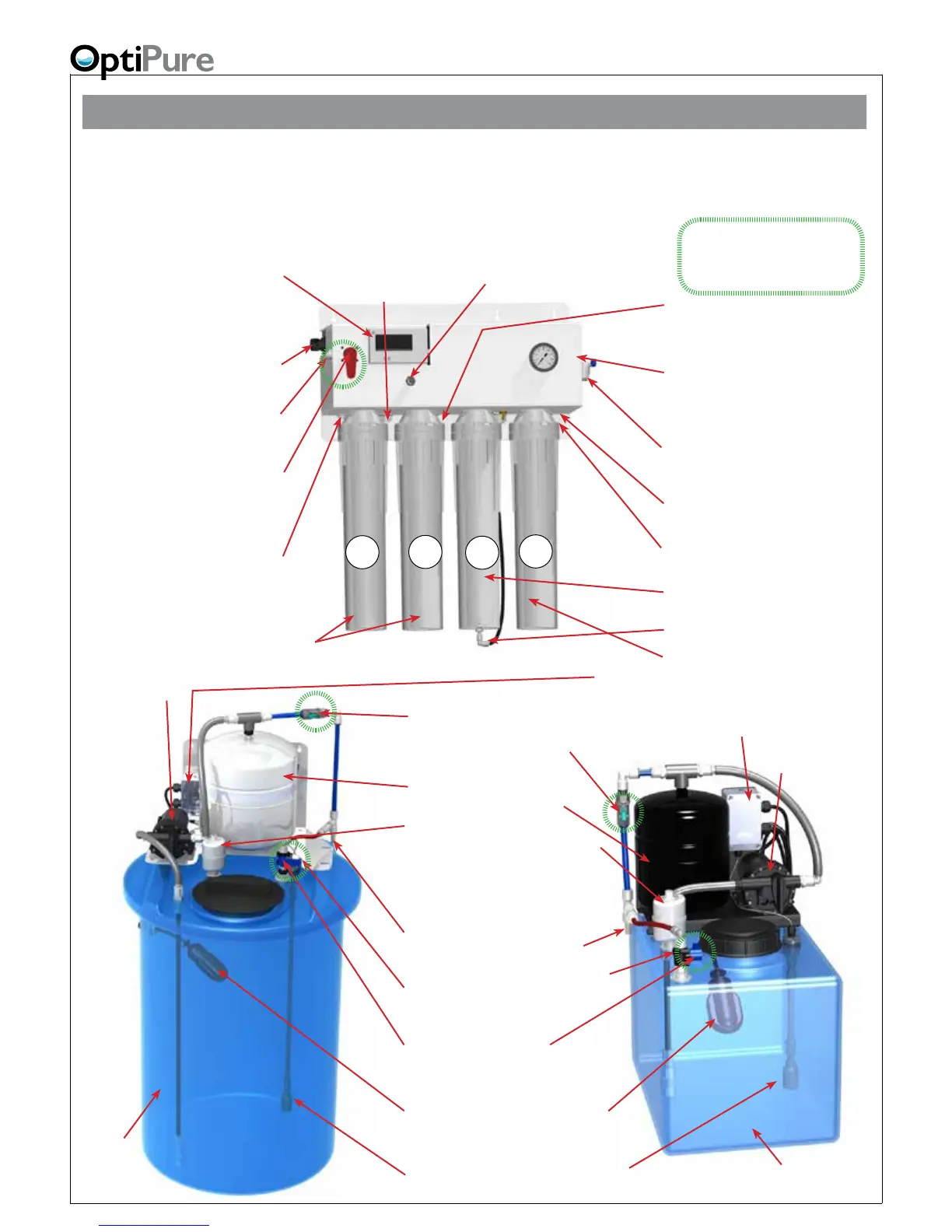

Getting To Know Your System

Feed Water Inlet

3/8” Push-To-Connect -

Connect to Water Supply Valve.

CTO-Q (2x)

Pre-Filters

Water Quality Indicator - Operates

momentarily, push purple button to turn on.

Push “IN” button for the TDS of the water

going into your equipment. Push “OUT”

button for the TDS of the puried water from

the membrane.

Emergency Bypass Valve -

User can switch from Optimized

Water to Untreated Water

when needed, by turning handle

horizontal.

Optimized Water To

Storage Tank - 3/8” Push-To-

Connect - Connect to Optimized

Water Storage Tank Inlet

Membrane Reject Water

Tubing Connection

AMS-QT Membrane

Cartridge

Reject Water Outlet - 1/4”

Push-to-Connect - Connect to drain

per local regulations.

1

2

3

Tank

Repressurization Return-

1/2” gray hose - Connect to

Repressurization Assembly Outlet

Pressurized

Optimized Water Outlet -

1/2” gray hose

-Connect to End User Equipment

Sample Port -

3/8” Push-to-Connect - Used to ush pre

lters, gather a water sample, measure pro-

duction, or drain water from storage tank.

Blending Valve - Allows

precise adjustment of optimized

water TDS (mineral content).

120VAC or 230VAC Power Cord

- Plug in to standard wall outlet.

Reject Flow Control Valve

Operating Pressure Gauge

Shows feed pressure only when processor is

operating (when level in storage tank is low).

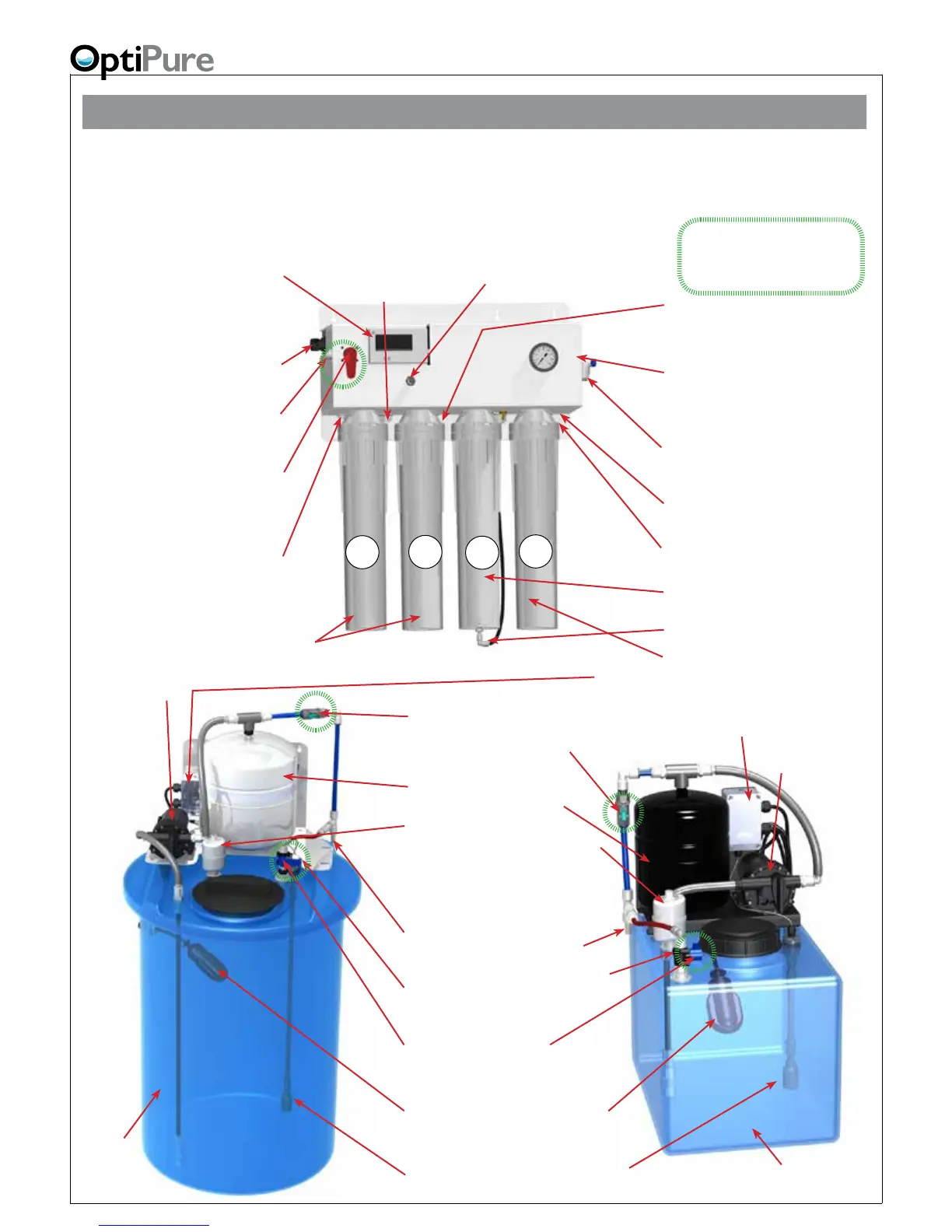

Normal

Operation

Items in green circles show a nor-

mal operating condition/position.

Optimized Water to Storage Tank

Inlet (on Valve)

- 3/8” Push-to-Connect - Connect to Opti-

mized Water Outlet on Processor.

Absolute 0.2 micron

Hydrophobic Air-Breather/Filter

Repressurization Assembly

Outlet - 1/2” Hose Barb - Connect to

Pressurized Water Inlet on Processor

Repressurization

Pump

120VAC or 230VAC -

Plug in to

standard wall

outlet

Repressurization

Pump

Buffer Tank

- Pre-charged air bladder - 20 psi

Optimized Water Storage Tank

- 16 gal. Atmospheric

Optimized

Water

Storage Tank

- 50 gal. Atmospheric

Buffer Tank Valve

- Normally open (handle parallel to

valve body). Used to shut off water

supply to downstream equipment.

High Level Float Switch (in Tank)

& Cable (on back or side of tank) - Connect

Cable to Processor “Tank Electrical Connection.”

Tank Inlet Divert Valve

- Normally in Down position. Turn handle to Up

position to divert Optimized water to sample port.

Low Level Float Switch (in Tank)

- Shuts off pump (using Relay) when tank is empty.

Low Level Relay & Control Box -

120VAC or

230VAC

- Plug in cord to standard wall outlet. Box

connected to LL Float Switch & Pump. Light on top

illuminates when there is water in tank & Pump is enabled.

4

MA-Q15 Mineral

Cartridge

Loading...

Loading...