BWS350 System Installation, Operation & Maintenance 7

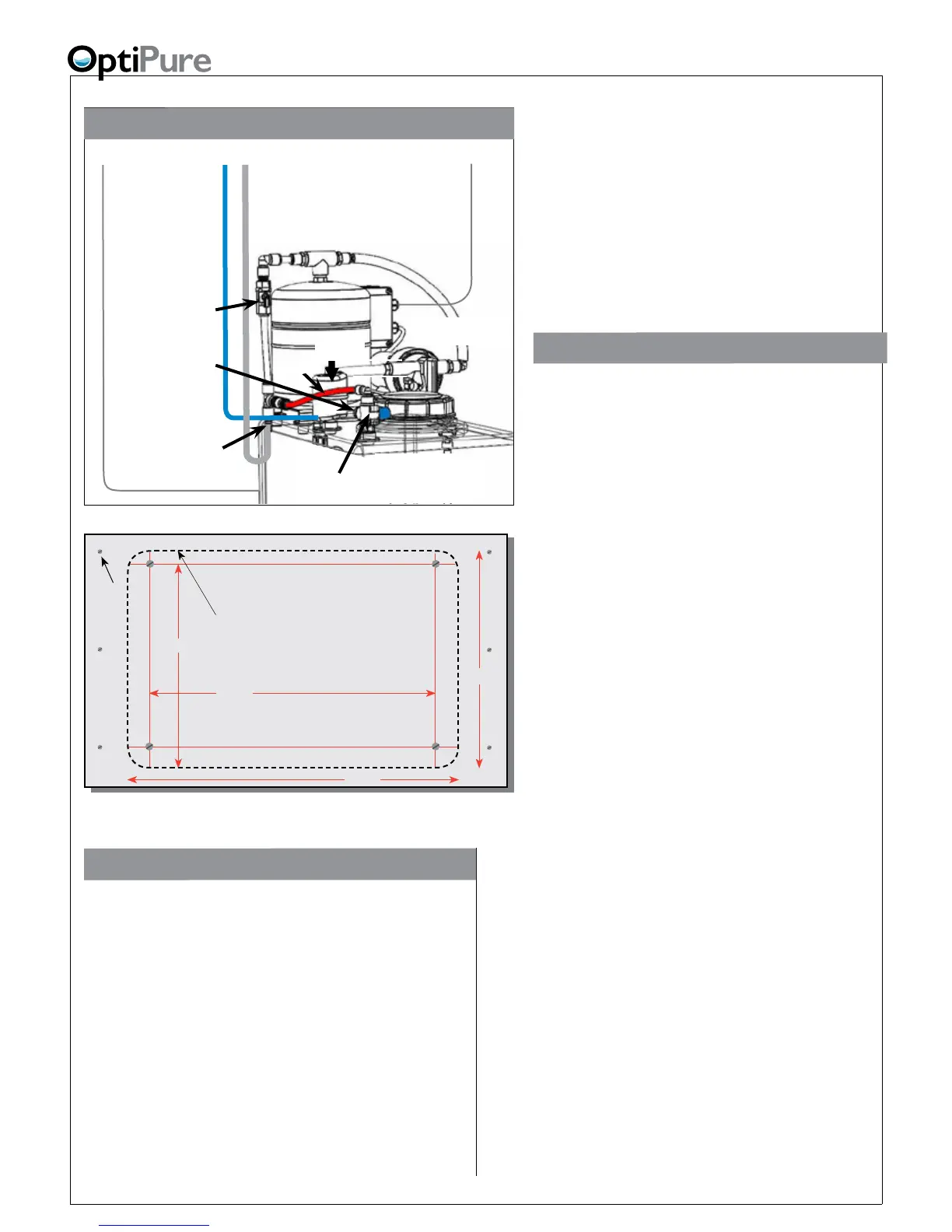

Wall Mounting

The processor should always be mounted where it

is well-supported, either using anchors in a cement

wall, or using the support of studs in a wall-board

wall. Never mount it directly to sheet-rock alone.

Instead, mount it on a sheet of plywood which is

anchored to the wall studs, as shown above.

Four user-supplied bolts or screws with a head

diameter of approximately 1/2” (which will t into the

keyholes in the system bracket, but will not slip out

when tightened) should be used to hang the system.

This will allow the unit to be lifted off the bolts, if

necessary for maintenance, without removing all

the bolts from the wall. Hold the processor in place

(without the cartridges) to mark the locations

for the screws. BE SURE TO ALLOW 3”

BELOW THE CARTRIDGES TO ALLOW FOR

REMOVAL. Screw the four bolts or screws in

place, leaving approximately 1/4” clearance

between the bottom of each bolt head and the

wall. Position the system over the mounting

bolts, and let the bracket slip down into the

keyholes. Tighten all screws.

System Installation

Note: Do not install the cartridges in the

processor until completing this section.

Do not plug in the power cord from the RP

pump until completing the following section,

“System Start-Up”.

Refer to “Typical Installation” diagram on

page 6 and “How to Use Our Quick-Connect

Fittings” on page 20 when making the

following connections.

A feed water ball valve and pressure gauge (user

supplied) should be installed to provide water to

the system FEED WATER INLET with the green

tubing (supplied). Hose, tubing and ttings for

making connections between the processor,

storage tank and drain are supplied in the

installation kit.

1. Remove the tank lid. Inside the tank, the oat

valve may be secured for shipping. Remove

any wrapping on the oat to allow it to hang

and move freely.

2. DRAIN: Connect the 1/4” black tubing from

the installation kit to the REJECT WATER

OUTLET on the processor. Run the line to

an appropriate drain. Observe local plumbing

codes and supply an appropriate air gap.

(Any ttings for connecting to the drain will

need to be supplied by the customer.) Fix

tubing in place at the drain.

3. FEED WATER: Apply 3 ‘wraps’ of Teon tape

to the 1/2” FPT x 3/8” push-connect tting

(supplied). Screw the tting into the Feed

Water Supply Ball Valve and tighten (DO

NOT OVERTIGHTEN). Connect one end

of the 3/8” GREEN TUBING to this tting.

Connect the other end of the tubing to the

FEED WATER INLET located on the left

side of the Processor. Cut the tubing to the

required length if necessary.

Plywood anchored to wall

10.5”

14.7”

8.9”

12.7”

Outside edge of

processor bracket

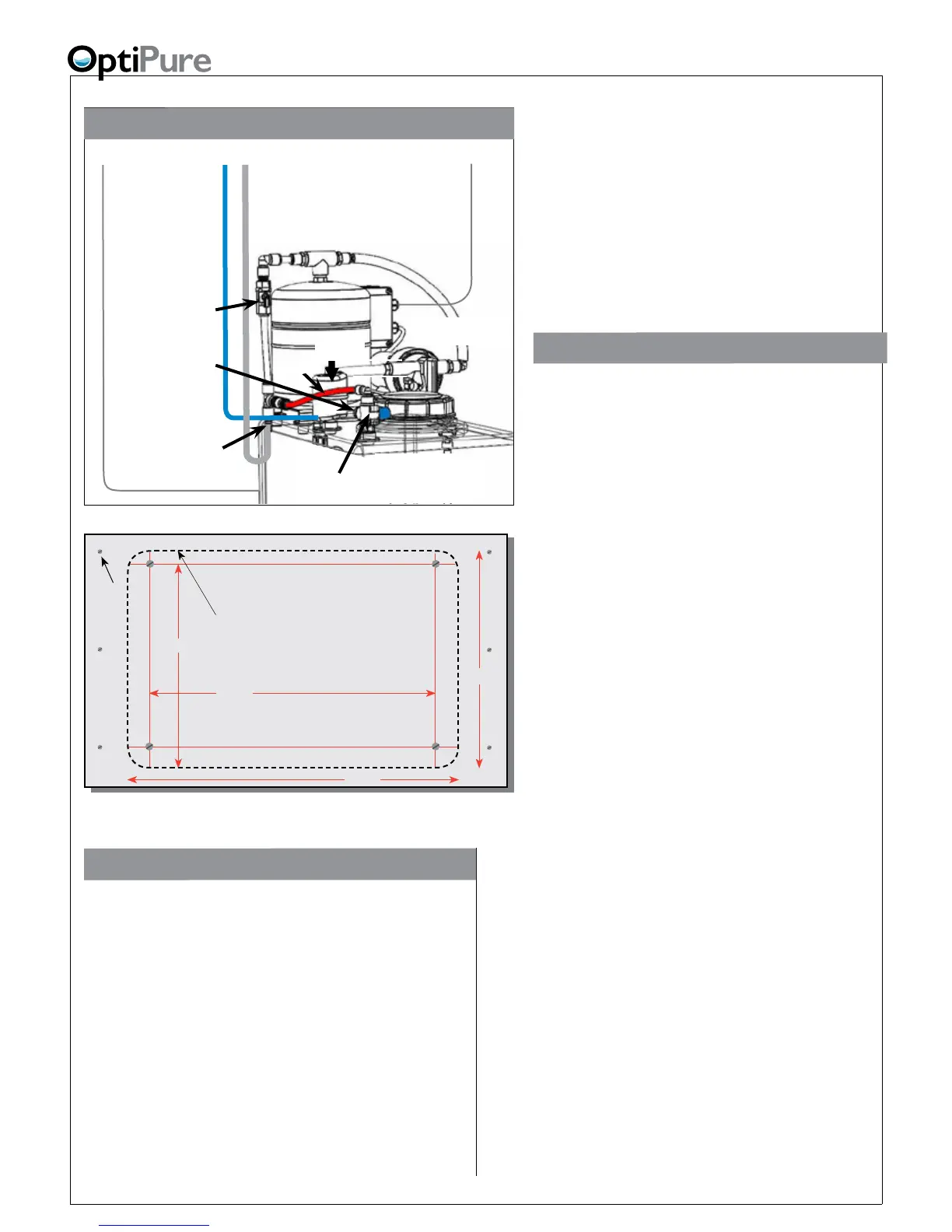

Installation with 16 Gal. Storage Tank

Optimized Water

Line

- Connect to

Processor Optimized

Water Outlet

Optimized

Water to

Storage Tank Inlet

(on Valve)

Repressurization

Assembly Outlet

(Hose Barb)

Repressurization

Pump

Buffer Tank

Buffer Tank

Valve

(Normally Open)

Optimized Water

Storage Tank

- 16 gal. Atmospheric

Tank Inlet

Divert Valve

Refer also to “Typical Installation” Diagram on previous page.

Power Cord

-to

120VAC or 230VAC

Outlet

Pressurized

Water Line

- connect to

Processor Tank

Repressurization

Return

High Level Switch Cable

-Connect to electrical box on

left side of Processor

Bypass

Air

Breather

Loading...

Loading...