Reverse flails if the cutting side is worn out, in order to use the other side.

Check that ALL the flails of the rotor are bolted and in good condition

Check thightening of hexagonal screws according to the chart at the end of the manual.

CAUTION

Use only original genuine OREC parts. Other parts may be dangerous for your

health and for the bystanders and the machine. If some flails are missing, big

vibrations will occur. If you feel such vibrations on the handlebar, check the rotor

and the flails. Vibrations may loosen the bolts and nuts and may crack the steel of

the machine.

TIGHTENING OF BOLT AND NUTS

•Check for tightening of bolt and nuts according to the chart. Vibrations of the

machine may loosen bolt and nuts.

LUBRICATION :

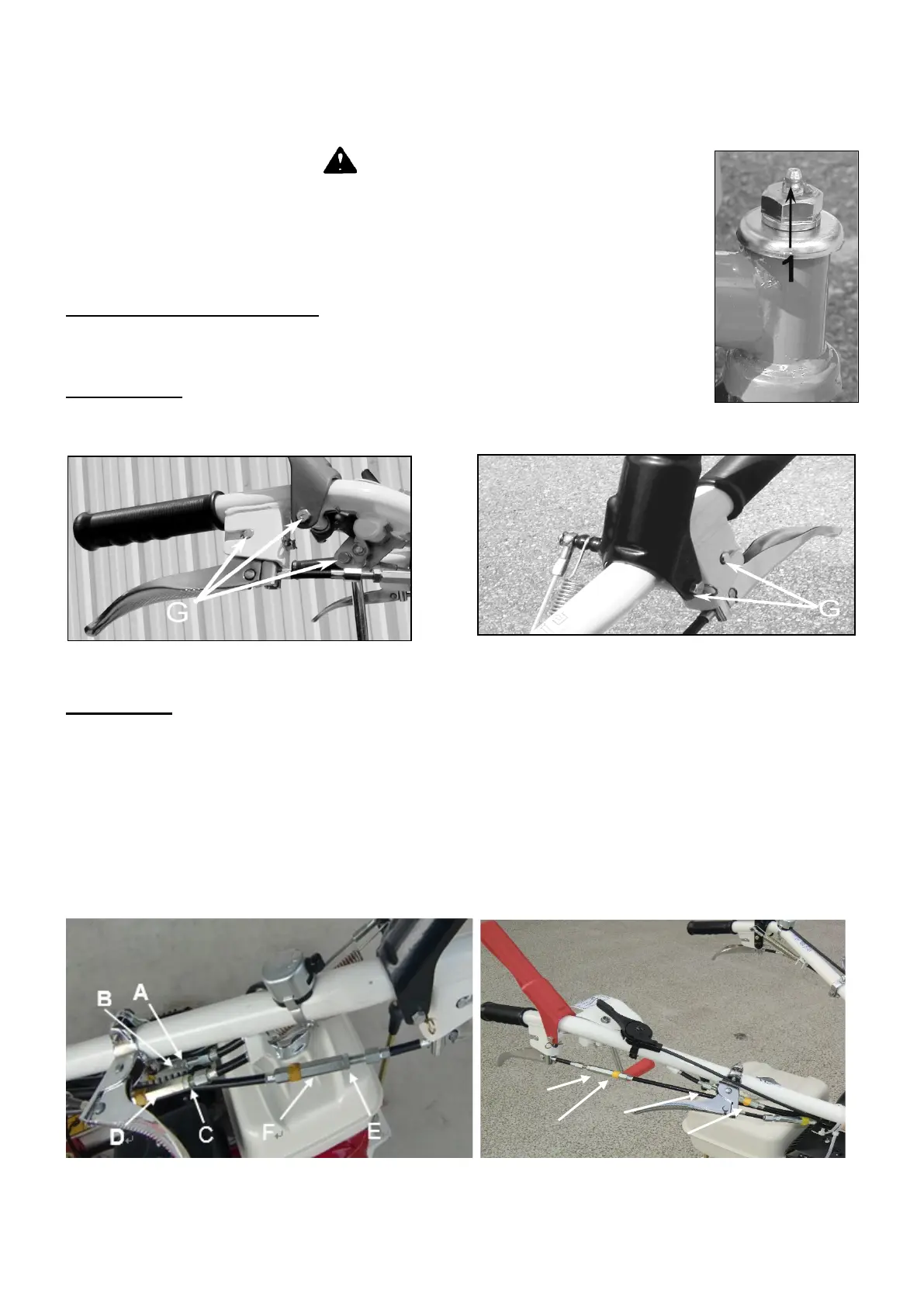

Grease the front wheel axle(1 Figure 15) with grease NLGI N°2.

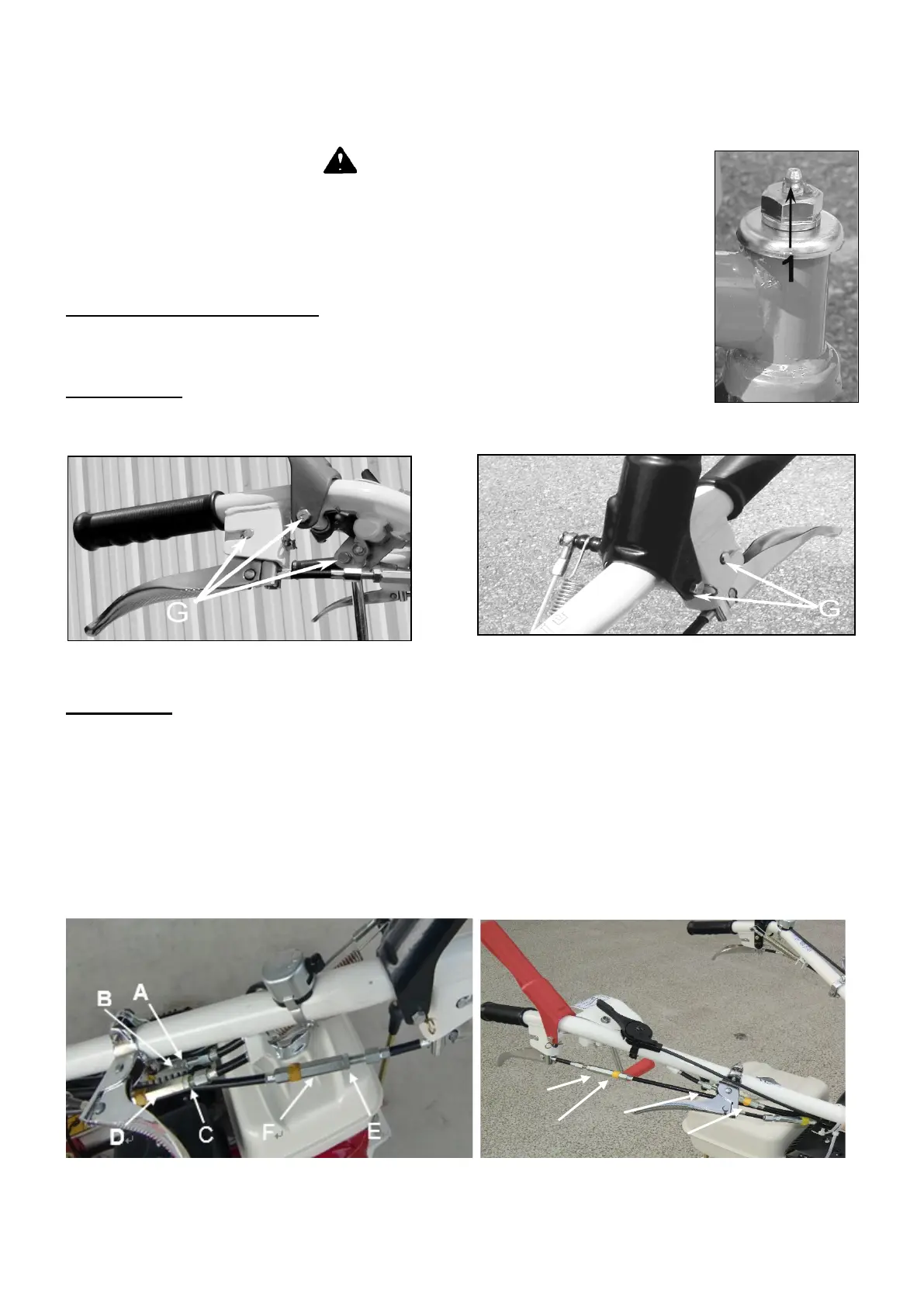

Grease the differents points G(Figures 16 & 17) with light oil.

WIRES GAP :

Transmission wires :

•If the machine does not stop when the drive clutch lever is released, adjust the tension wire as follow :

unscrew the locking screw (A, Figure 18) and unscrew the nut (B, Figure 18). Try the machine again.

Perform the adjustment again if needed. When the adjustment is performed, screw the locking screw

(A, Figure 18) on the nut (B, Figure 18).

•

If the machine does not move when driving clutch lever is pressed, adjust the tension wire as follow : unscrew

the locking screw (C, Figure 18) and unscrew the nut (D, Figure 18). Try the machine again. Perform the

adjustment again if needed. When the adjustment is performed, screw the locking screw (C, Figure 18) on the nut

(D, Figure 18)

.

Blade wire :

Loading...

Loading...