- 20 -

3. Inspection before work

●Before starting work, check "1.2 Before Starting Work" and check the following "Before

starting work checklist" and Be sure to perform the pre-operation inspection according

to "7.1 Periodic inspection table".

※If you have any questions or problems, please be sure to contact the dealer where you

purchased the product.

1) Be sure to stop the engine before Checking, Refueling, Adjusting or Servicing.

2) When starting the Engine and Checking the operation of the Driving clutch lever etc.,

Check the safety of each Lever position and the surrounding of machine.

3) Make sure you understand the warning markings on the Machine.

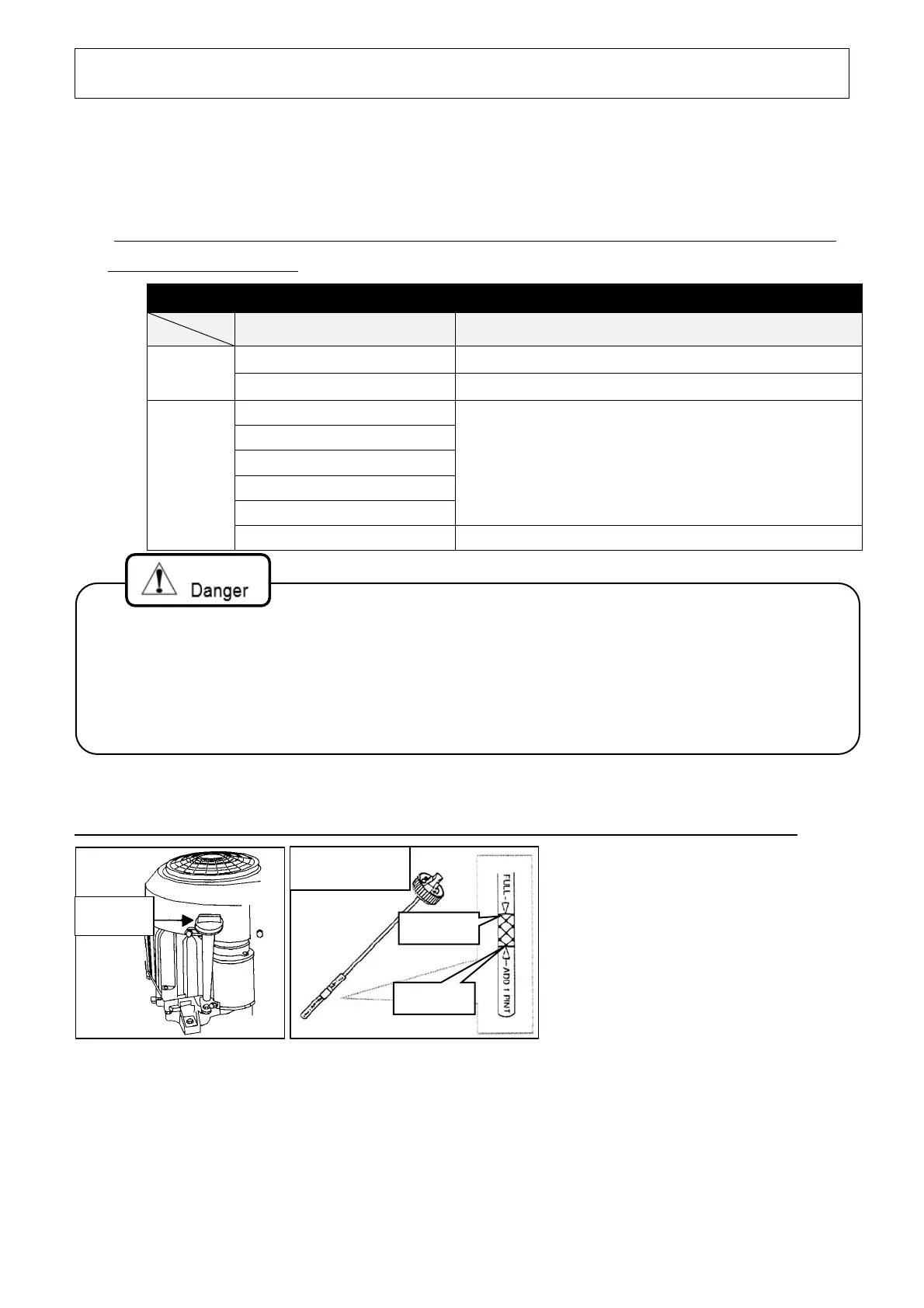

3.1 Check engine oil

① Level the machine and remove

the oil gauge.

② The tip of the Oil plug is an

oil gauge. Wipe the gauge part

with a cloth、Place the engine

horizontally、Briggs Engine : screw

in oil plug、Kawasaki Engine only

insert oil plug without screwing、Check the amount of oil. If there is no oil mark between

the upper and lower scale lines, add engine oil so that the oil reaches the upper scale line.

Pre-operation checklist (summary from regular checklist))

Item

Inspection contents

Engine

①

Engine oil

Check "oil amount and dirt" <Refer to 3.1>

② Air cleaner

Check for "dirt" and clean <5.2.1>

Machine

Body

① Blade (Knives)

<Refer to 5. Inspection and maintenance>

"1" bolts and nuts are loosened or dropped

"2" Deformation, wear, interference

"3" Smooth movement or Sticking

"4" Remove foreign matter such as garbage, grass and straw

② Brake (Applicable product)

③ Tire (crawler)

④ Levers

⑤ Covers

⑥ HST oil (Applicable products) Check "oil amount and dirt"

oil plug

Oil gauge

U

er

Lower

Loading...

Loading...