4

Connection

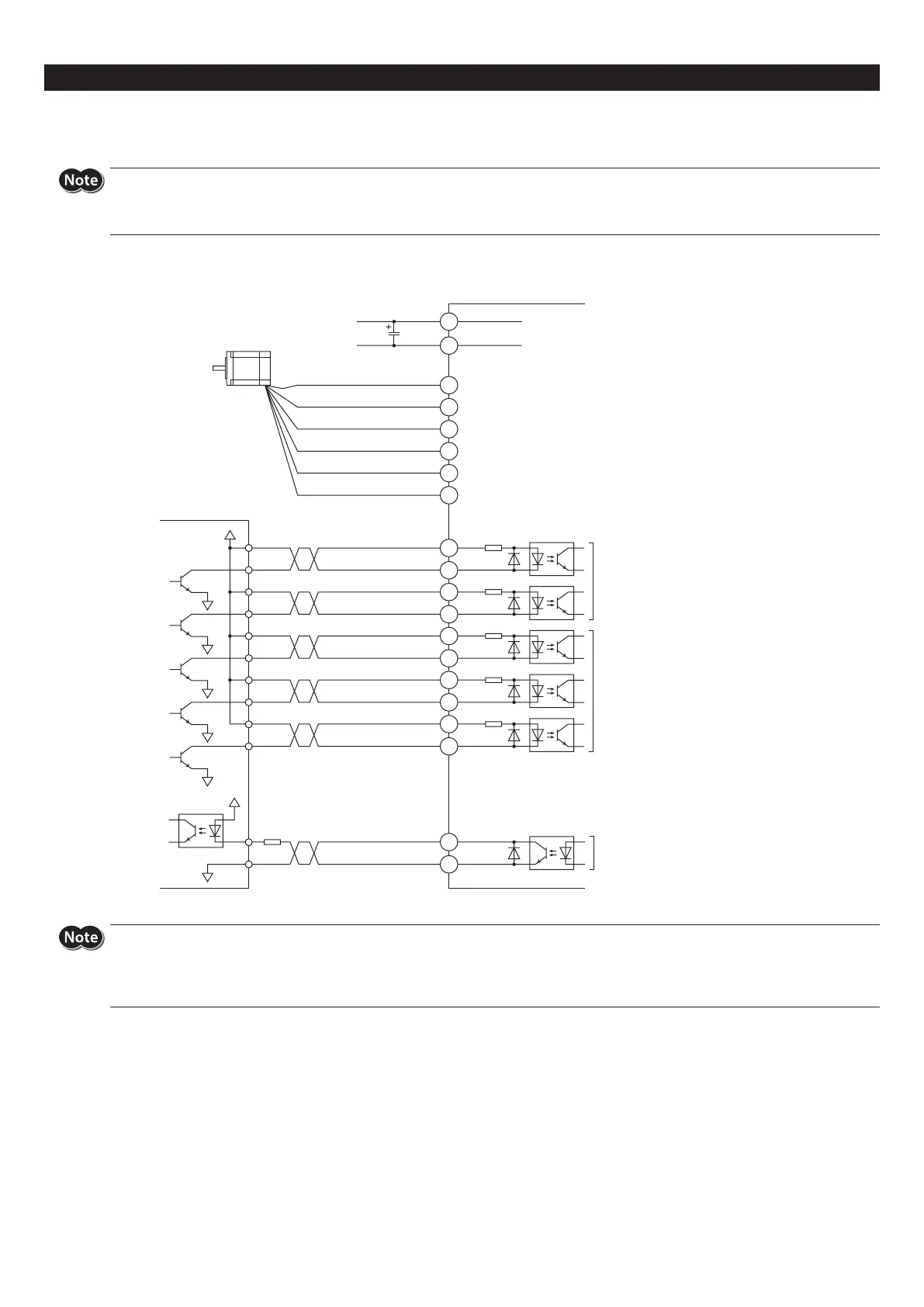

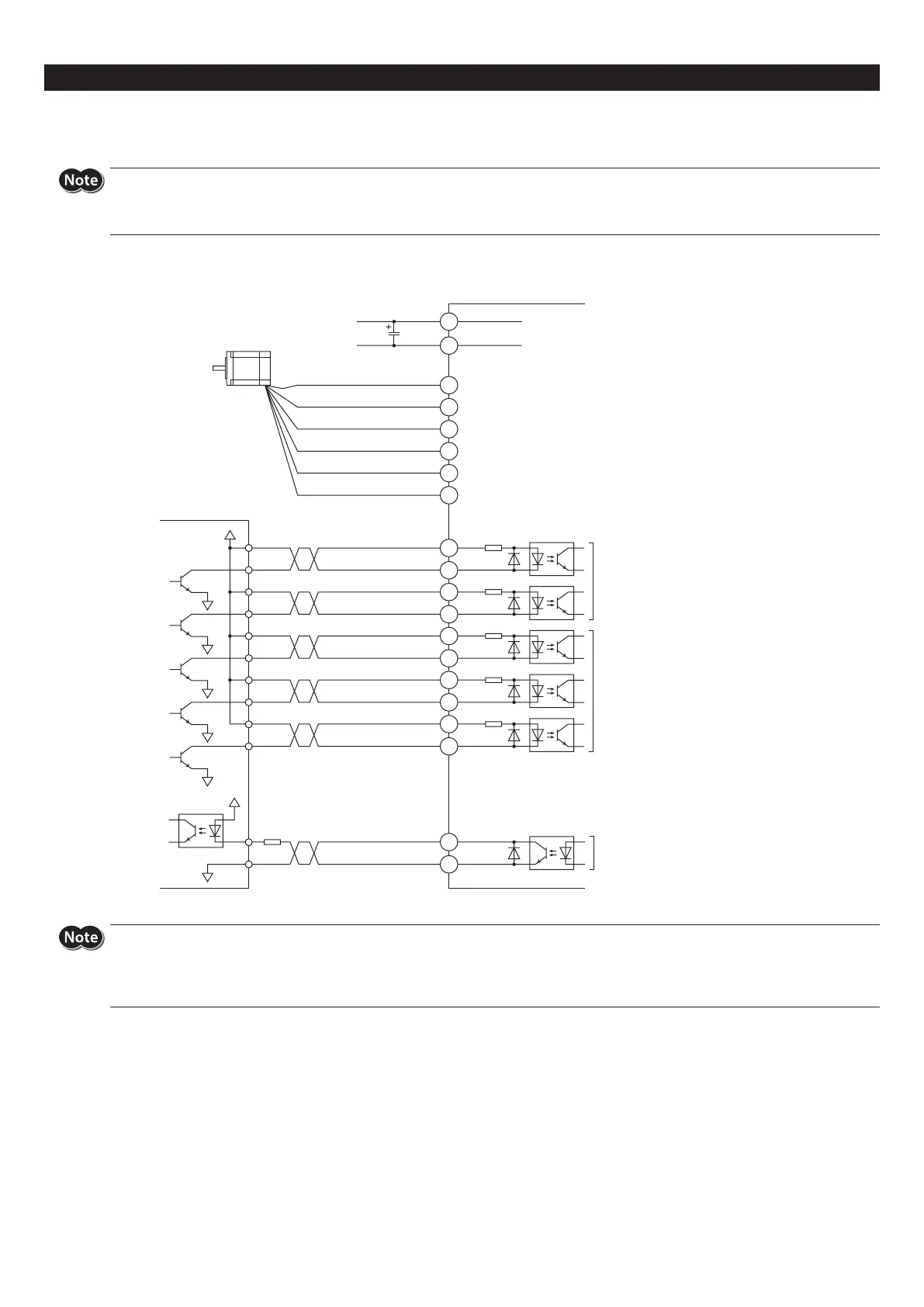

Connection example

Either 5 or 24 VDC can be used as the signal voltage for the AWO input, CS input and ACDOFF input.

y

Check the colors of motor lead wires and connect them correctly and securely. Wrong connection of lead wires or poor contact may cause damage to the

driver.

y

Be sure to wire the I/O signals cable connecting the driver and controller as short as possible. The maximum input frequency will decrease as the cable length

increases.

z

When using the voltage of input signals at 5 VDC

Blue

Red

White

Green

Yellow

Black

V0 (5 VDC)

V0 (5 VDC)

GND

24 VDC±10%

Motor lead wire *

Controller

Photocoupler input

5 VDC

Input current 5 to 20 mA

Photocoupler input

5 VDC

Input current 1 mA

Photocoupler/open-collector output

5 to 24 VDC

Output current 10 mA or less

R2

200 Ω

200 Ω

3.3 kΩ

3.3 kΩ

3.3 kΩ

DIR

-

(CCW

-

)

PLS

-

(CW

-

)

PLS+ (CW+)

DIR+ (CCW+)

AWO

-

AWO+

CS

-

CS+

TIM

-

TIM+

ACDOFF

-

ACDOFF+

CN1

CN3

CN2

1

2

+

1

2

3

4

6

5

-

3

4

5

6

7

8

9

10

11

12

0 V

0 V

0 V

0 V

0 V

0 V

C

Twisted pair cable

* Connector pin assignments vary depending on the motor. For details, refer to "Connecting the motor" p.5.

y

If the output signal current exceeds 10 mA, connect external resistor R2 to keep the current to 10 mA or below.

y

Driving a large inertia at high speed will generate regenerated energy. This regenerated energy raises the power supply voltage, causing damage to the

driver. If such operation is performed, review the operating condition so that the temporary rise of the power supply voltage by the regenerated energy is

8 V or less, or connect an electrolytic capacitor C in parallel to the power line (A rated voltage of 50 V or more and a capacitance of 10,000 µF or more are

recommended).

Loading...

Loading...