11

y

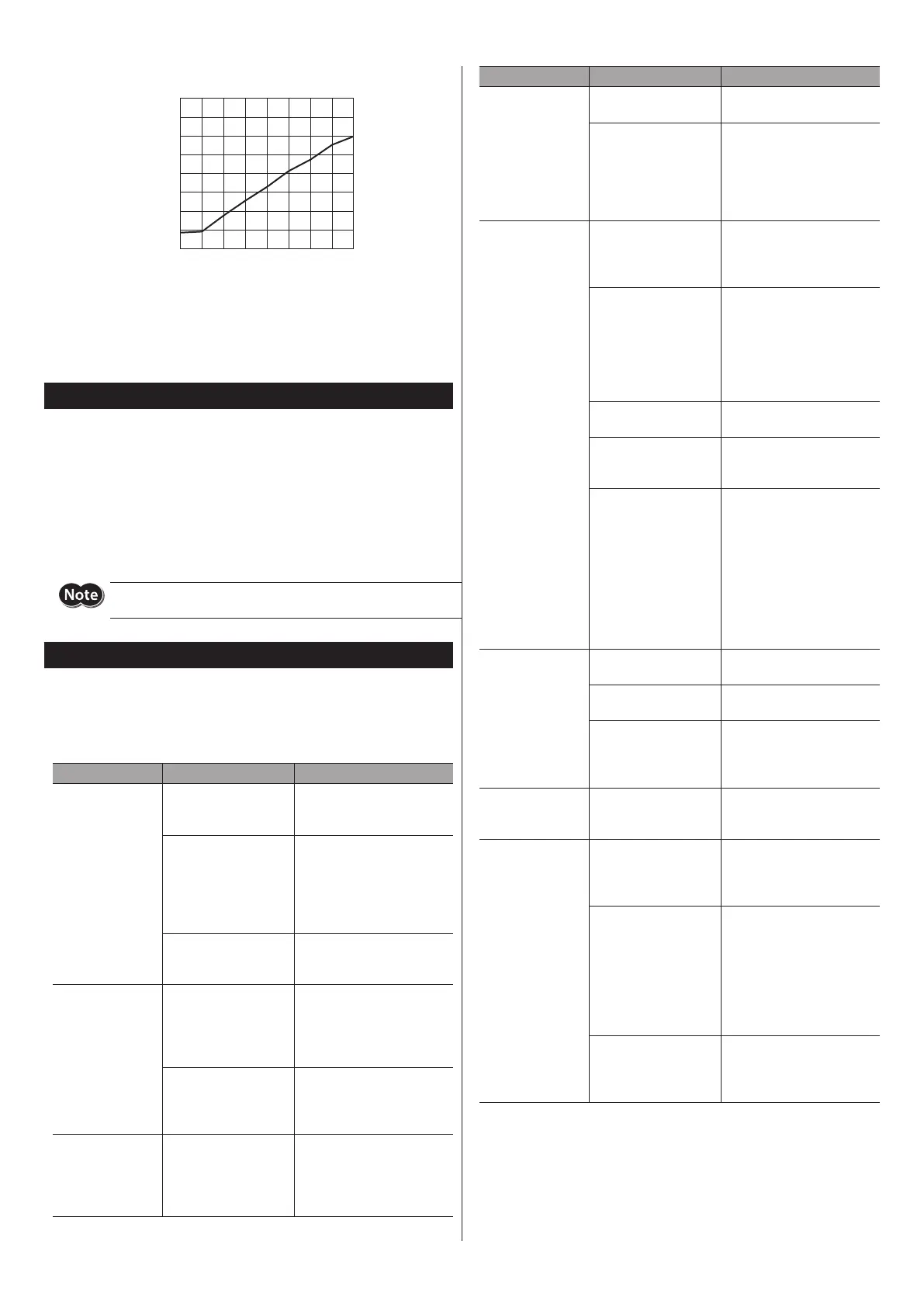

CMD2120P

[Representative values]

0

10

20

30

40

50

60

70

80

12345678

STOP potentiometer

Current-cutback ratio (%)

4. When the setting is complete, turn o the power supply.

After about 0.1 second has passed since the pulse was stopped, the

motor’s operating current automatically decreases to the set value of

current at motor standstill.

Inspection

It is recommended that periodic inspections are conducted for the items

listed below after each operation of the motor. If an abnormal condition is

noted, discontinue any use and contact your nearest Oriental Motor sales

oce.

Inspection item

y

Are any of the mounting screws having installed the driver or connection

parts of the driver loose?

y

Is there attachment of dust, etc., on the driver?

y

Are there any strange smells or appearances within the driver?

The driver uses semiconductor elements, so be extremely careful when

handling them. Static electricity may damage the driver.

Troubleshooting and remedial actions

During motor operation, the motor or driver may fail to function properly due

to an improper speed setting or wiring. When the motor cannot be operated

correctly, refer to the contents provided in this section and take appropriate

action. If the problem persists, contact your nearest Oriental Motor sales

oce.

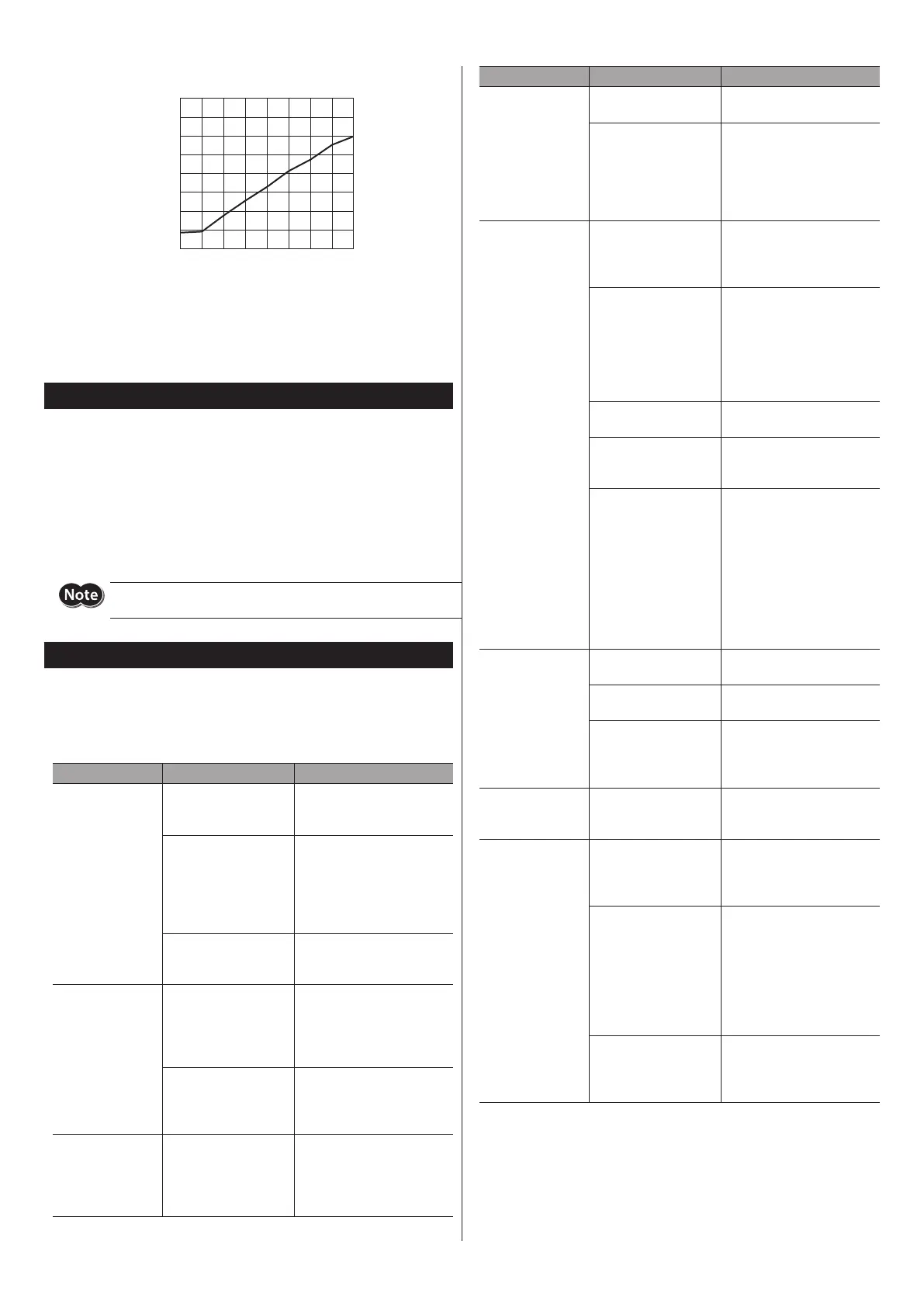

Phenomenon Possible cause Remedial action

y

The motor is not

excited.

y

The motor’s

output shaft can

be turned easily by

hand.

Connection error in the

motor or power supply.

Check that the connections

between the driver, motor and

power supply are correct.

Motor operating current

incorrectly set. If the

setting is too low, the

motor torque will also be

too low and operation

will be unstable.

Return the motor operating

current to its factory setting

and check.

The AWO input is set to

ON.

Switch the AWO input to OFF

and conrm that the motor is

excited.

The motor does not

run.

Pulse input line

connection error.

y

Check the controller and

driver connections.

y

Check the pulse input

specications (voltage and

width).

The CW input and the

CCW input came ON at

the same time.

Input either the CW input or

the CCW input, and always

switch the other terminal to

OFF.

The motor rotates

in the direction

opposite that which

is specied.

The CW input and the

CCW input are connected

in reverse.

Connect the CW pulses to the

CW input (pin Nos.1 and 2),

and connect the CCW pulses

to the CCW input (pin Nos.3

and 4).

Phenomenon Possible cause Remedial action

Motor operation is

unstable.

Motor connection error.

Check that the driver and

motor connections are correct.

Motor operating current

incorrectly set. If the

setting is too low, the

motor torque will also be

too low and operation

will be unstable.

Return the motor operating

current to its factory setting

and check.

Loss of

synchronization

during acceleration

or running.

The centers of the

motor’s output shaft

and load shaft are not

aligned.

Check the connection

condition of the motor output

shaft and load shaft.

The load or load

uctuation is too high.

Check for large load

uctuations during motor

operation. If adjusting the

motor’s operating speed to

low and high torque eliminates

the problem, it is necessary to

review the load conditions.

The speed of the starting

pulse is too high.

Lower the speed of the starting

pulse.

The acceleration

(deceleration) time is too

short.

Lengthen the acceleration

(deceleration) time.

Eect of electrical noise.

Check running with only the

motor, driver and required

controller. If the impact of

noise is recognized, take

countermeasures, such as

rewiring for greater distance

from the noise source,

changing the signal cables to

shielded wire, or mounting a

ferrite core.

Motor does not

move the set

amount.

Mistake in switching CS

input.

Check the CS input state.

Wrong step angle

settings.

Check the settings of the step

angle setting switches.

Pulse output count is too

low or too high.

Check whether or not the

number of pulses required for

operation at the set step angle

are being output.

Current does not

drop when the

motor stops.

The ACDOFF input is set

to ON.

Switch ACDOFF input to OFF.

Motor vibration is

too loud.

The centers of the

motor’s output shaft

and load shaft are not

aligned.

Check the connection

condition of the motor output

shaft and load shaft.

Motor is resonating.

If the vibration decreases

when the operating pulse

speed is changed, it means

the motor is resonating.

Change the operating pulse

speed setting or install a

clean damper (accessory) to

suppress vibration.

Load is too small.

Lower the motor operating

current. Vibration will increase

if the motor’s output torque is

too large for the load.

Loading...

Loading...