7

y

Grounding multiple points will increase eect to block electrical noise

because impedance on the grounding points is decreased. However,

ground them so that a potential dierence does not occur among the

grounding points. A connection cable (for signal) that includes a ground

wire is provided. Refer to p.12 for details.

y

To ground a shielded cable, use a metal cable clamp that will maintain

contact with the entire circumference of the cable. Ground the cable clamp

near the product.

Cable clamp

Shielded cable

•

Suppression of eect by noise propagation

y

Loop the noise propagated cable around a ferrite core. Doing so will

prevent the propagated noise invades into the driver or emits from the

driver. The frequency band in which an eect by the ferrite core can be

seen is generally 1 MHz or more. Check the frequency characteristics of the

ferrite core used. To increase the eect of noise attenuation by the ferrite

core, loop the cable a lot.

y

Use the line driver type, which is less likely to be aected by electrical noise,

for the output circuit of pulse signals. If the pulse signal of the controller is

of the open collector type, use a pulse signal converter for noise immunity.

Refer to p.12 for details.

z

Noise suppression parts (accessories)

Refer to p.12 for accessory.

•

Connection cable (for signal)

This cable is a shielded twisted pair cable for good noise immunity to connect

the driver and controller. The ground wires useful to grounding are provided

at both ends of the cable. The EMC measures are conducted using the

Oriental Motor connection cable (for signal).

•

Pulse signal converter for noise immunity

This is a noise lter for pulse signal lines. It eliminates the noise of the pulse

signal, and converts the pulse signal to the line driver type.

•

Surge suppressor

This product is eective to suppress the surge which occurs in a relay contact

part. Connect it when using a relay or electromagnetic switch. CR circuit for

surge suppression and CR circuit module are provided.

Conformity to the EMC Directive

Eective measures must be taken against the EMI that the motor and driver

may give to adjacent control-system equipment, as well as the EMS of the

motor and driver itself, in order to prevent a serious functional impediment in

the machinery. The use of the following installation and wiring methods will

enable the motor and driver to be compliant with the EMC Directive. Refer to

p.2 for the applicable standards.

Oriental Motor conducts EMC measurements on its motors and drivers in

accordance with the "Example of motor and driver installation and wiring"

shown later.

The user is responsible for ensuring the machine's compliance with the EMC

Directive, based on the installation and wiring explained below.

•

Power supply

The

CMD

Driver is a product of DC power input. Use a DC power supply

(switched-mode power supply etc.) that conforms to the EMC Directive.

•

Connecting the signal cable

Refer to "Prevention of noise propagation" p.6.

•

How to ground

y

The cable used to ground the motor, driver and noise lter must be as thick

and short as possible so that no potential dierence is generated.

y

Choose a large, thick and uniformly conductive surface for the grounding

point.

y

Install the motor to the grounded metal plate.

•

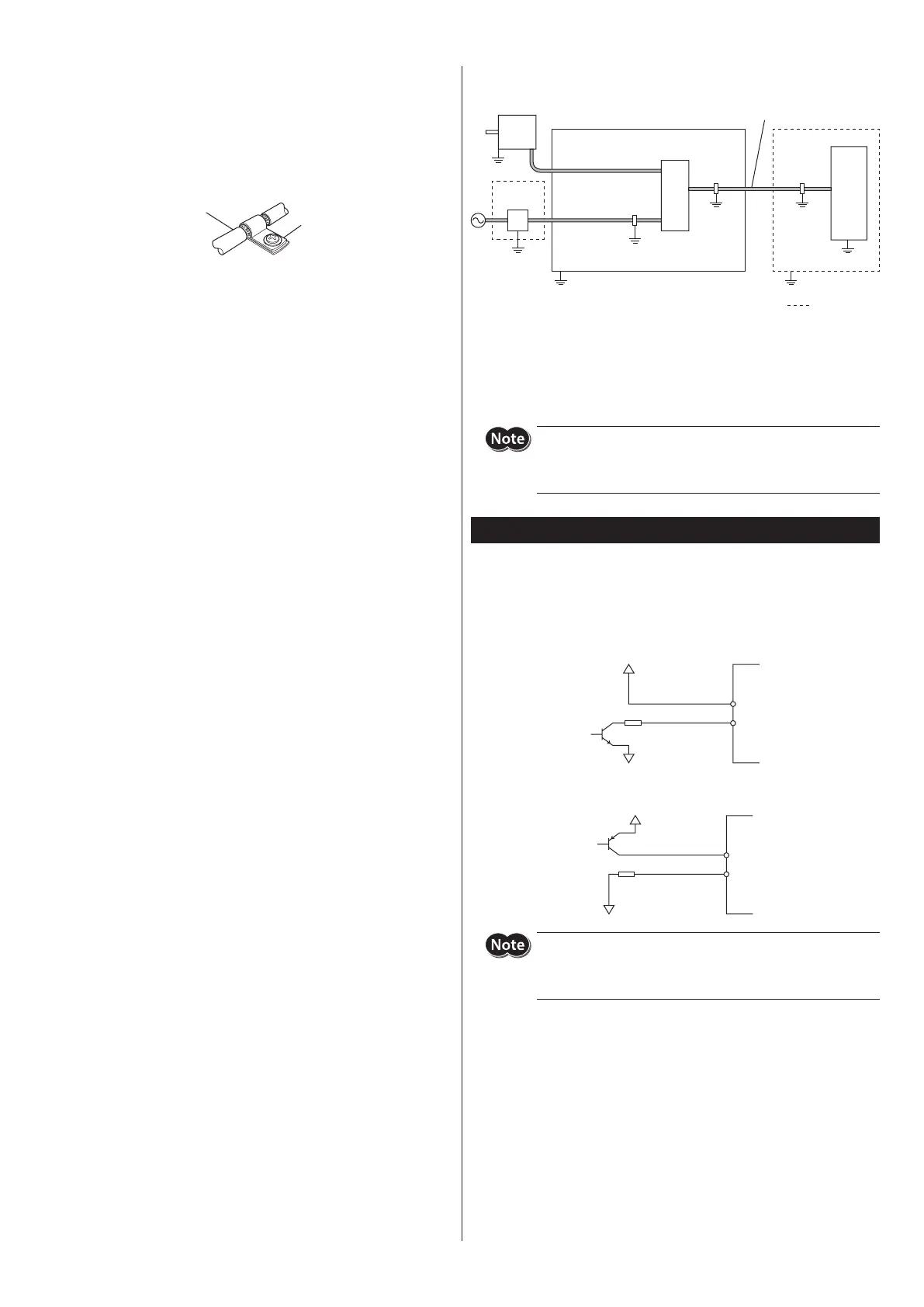

Example of motor and driver installation and wiring

Motor

Driver

DC power

supply

Cable

clamp

Cable

clamp

Grounded panel

Cable for motor

Controller

Power supply

cable

(connection cable)

Cable

clamp

Grounding

Grounding

Grounding

Grounding

Grounding Grounding

Grounding

Grounding

•

Precautions about static electricity

Static electricity may cause the driver to malfunction or suer damage. While

the driver is receiving power, handle the driver with care and do not come

near or touch the driver.

Always use an insulated screwdriver to adjust the driver's switches.

The driver uses parts that are sensitive to electrostatic charge. Before

touching the driver, turn o the power to prevent electrostatic charge

from generating. If an electrostatic charge is impressed on the driver,

the driver may be damaged.

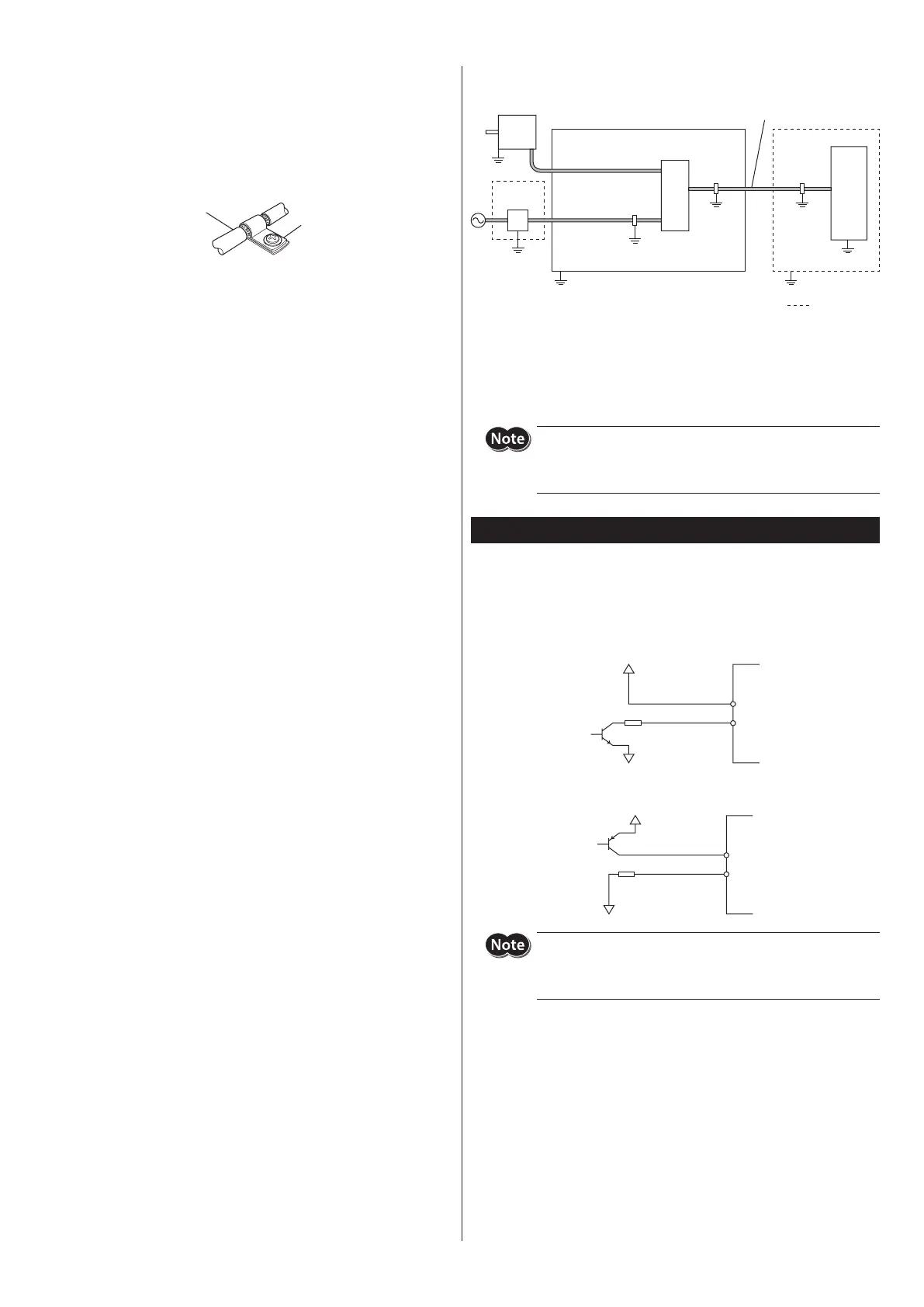

Explanation of I/O signals

Input signals

The signal input state represents "ON: Carrying current" or "OFF: Not carrying

current" state of the internal photocoupler.

•

Example of connection with a current sink output circuit

1, 3, 5, 7, 9

2, 4, 6, 8, 10

•

Example of connection with a current source output circuit

1, 3, 5, 7, 9

2, 4, 6, 8, 10

The PLS (CW) input and DIR (CCW) input are of the 5 VDC input

specication. If V0 exceeds 5 V, connect an external resistor. The AWO

input, CS input and ACDOFF input can be connected directly to 5 VDC

or 24 VDC.

Loading...

Loading...