1.3 Multistretch control description

The multistretch drive is a solid state DC motor control especially designed for use in

constant tension mode on stretchwrapping machines. The unit functions as a pay-off

drive, unwinding the pre-stretched film as the turntable and pallet rotate, and

continuously regulating tension as the diameter of the wrapped load changes. Since the

typical pallet load is a square cross section, the effective diameter changes abruptly with

rotation; the film tension is monitored by a tension-arm, held in place by spring pressure.

As the film tension changes, the arm moves, rotating a cam, and the cam orientation is

sense by a hall effect transducer. The transducer is powered at 24VDC by a regulated

supply on the MCIA. The transducer signal varies with the separation between its

sensing head and the cam surface – the output range is from approximately 0.5 to 3.5

volts DC. The amplified transducer signal controls motor torque, increasing or

decreasing it so as to restore the tension arm to its previous position, and to maintain

tension at its preset level. The system response is tailored so that these small

corrections are smooth, continuous and largely imperceptible. The tension defaults to

minimum when the external tension adjustment circuit is opened.

ADJUSTMENTS:

The operator, using the digital interface can set the film tension. In addition to the

above-mentioned digital tension adjustment, there are three trimming potentiometers.

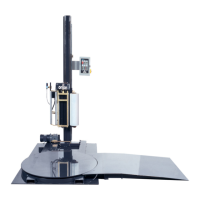

The trimmers are accessible through the faceplate of the plug-in control, (See Fig. 3),

functions as follows:

ZERO (RV1)

This control injects an offset voltage, which adds or subtracts from the tension voltage

reference; this will allow the extremes of adjustment from the digital interface to be set to

levels consistent with appropriate operation. Typically, the “Zero” will be used to center

the operating range in the linear portion of its characteristics. This adjustment is normally

made at the factory and should not require field adjustment. The machine should be

stopped and the film removed for this adjustment.

SPAN (RV2)

This controls the system loop gain, and may be adjusted if the motor continues to turn

when the dancer arm is unloaded. The potentiometer should be adjusted to ensure that

the motor is de-energized when arm is unloaded.

CURRENT LIMIT

To protect the unit against damage, if the motor should stall, jam, or current demands

exceed the rating, a current-limiting circuit is included which keeps motor current at a

safe level regardless of motor load, or input from the tension arm. The current limit is set

at the factory and should not require field adjustment.

CONNECTION

The motor armature attaches to terminals (+) (-) are accessible through the faceplate of

the plug-in module. The unit is suitable for permanent magnet shunt style DC motors

with 90 V armature rating, sized at up to 3/4HP.

Page 3

Loading...

Loading...