OSAKA – SMART BOX – Simple Manual – v1.1 – Page 10

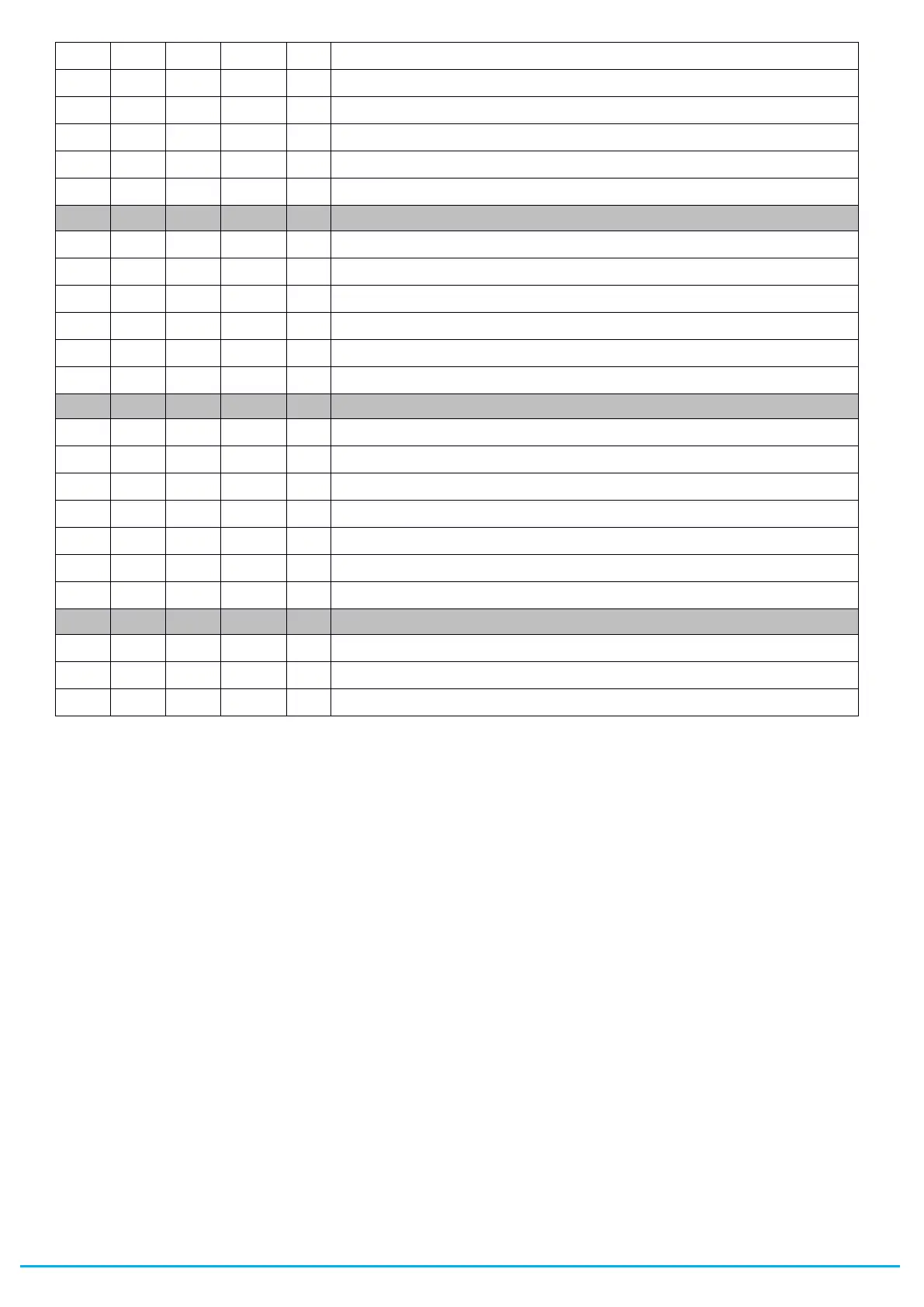

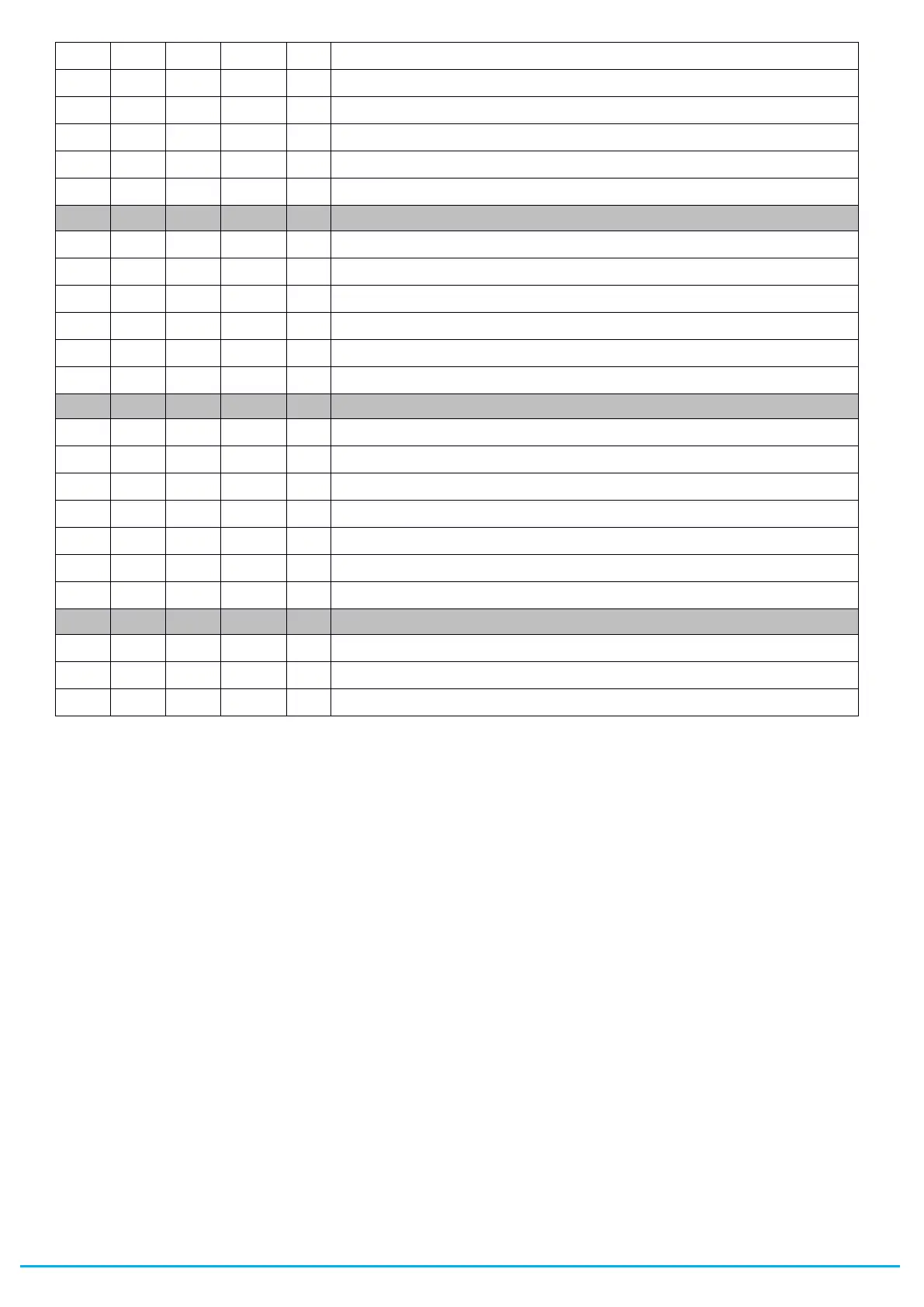

Hour of activation of the “energy saving” operation mode on Fridays.

Duration of the “energy saving” operation mode on Fridays.

Hour of activation of the “energy saving” operation mode on Saturdays.

Duration of the “energy saving” operation mode on Saturdays.

Hour of activation of the “energy saving” operation mode on Sundays.

Duration of the “energy saving” operation mode on Sundays.

Activation time of the first daily defrosting (h - - = not used).

Activation time of the second daily defrosting (h - - = not used).

Activation time of the third daily defrosting (h - - = not used).

Activation time of the fourth daily defrosting (h - - = not used).

Activation time of the fifth daily defrosting (h - - = not used).

Activation time of the sixth daily defrosting (h - - = not used).

Writing interval in the “HACCP” type modes.

Writing interval in the “service” type modes.

Duration of the “service” type writing mode.

Enable the auxiliary 3 temperature probe; 0 = NO; 1 = YES

Enable the writing of the value of the room temperature; 0 = NO; 1 = YES

Type of decimal separator; 0 = comma; 1 = Period

Type of auxiliary 2 and auxiliary 3 probe; 0 = Reserved; 1 = NTC; 2 = Pt1000

Device’s serial direction (node)

Transmission speed (Bauds); 0 = 2.400 bauds; 1 = 4.800 bauds; 2 = 9.600 bauds; 3 = 19.200 bauds

Parity; 0 = None; 1 = Odd; 2 = Even

Notes:

(1) The unity of measurement depends on the P2 parameter.

(2) The unity of measurement depends on the P9 and P10 parameters.

(3) Properly configure the parameters considering the value of the P2 parameter.

(4) The formula to calculate the CPT temperature is as follows:

CPT temperature = {[(P7 parameter) x (air input temperature) + [(100 – P7 parameter) x (air output temperature)] : 100}

(5) The value depends on the P2 parameter (0.1 °C or 1 °C)

(6) When working with only one compressor the parameter is the differential of the regulation Set Point. However, if one of the outputs is configured as compressor 2, r0

becomes the proportional band of a regulation with two stages.

- Temperature below the SP, disconnected compressors.

- Temperature above the SP+r0/2 (half of the band) the controller activates a compressor.

- Temperature above the SP+r0, the controller activates both compressors.

(7) The differential of the h02 and h03 parameters is 2.0 °C/4 °F

(8) The differential of the h13 parameter is 2.0 bar g/PSI g

(9) The pre-dripping is used with the hot gas defrostings and in parallel to the hot gas solenoid valve (which is controlled with the defrosting output); an electric resistance

of “evaporator drying” is also controlled.

How the regulation works:

When a hot gas defrosting is initiated the controller activates the compressor’s output and the defrosting output. This way the compressor, the hot gas solenoid valve and

the drying resistance will be activated.

When the defrosting finishes (when the evaporator has reached the “end of defrosting” temperature) the controller deactivates the compressor’s output but keeps the

defrosting output activated for the d16 time in order to keep the drying resistance activated for some minutes (usually it is 2 or 3 minutes).

After this the controller starts the dripping, where all outputs are deactivated. In general, the pre-dripping is used instead of the dripping when the installation has this

drying resistance.

(10) Example: if the compressor is working for 180 minutes straight without reaching the SP, the controller will perform a defrosting cycle due to the suboptimal

performance of the plant.

(11) Ignited fan during the “energy saving” mode, it doesn’t have an effect on the behavior during the defrosting. The F13 and F14 parameters have an effect when the

compressor is turned off.

(12) The F13 and F14 parameters have an effect when the compressor is ignited.

(13) The F13 and F14 parameters have an effect when the evaporator’s temperature is below the temperature set in the F1 parameter.

(14) The F13 and F14 parameters have an effect when the compressor is turned off and the evaporator’s temperature is below the temperature set in the F1 parameter.

(15) This alarm is only a signal in the controller’s display, the alarm output can be activated if it is configured.

(16) This parameter only has a function if one of the outputs is configured as a resistance for a dead-zone operation. In such a case, u7 establishes at how many

degrees below the working set point will the heat resistance be activated.

Loading...

Loading...