14 Part Number 550-110-772/0816

OSB

Series 2 Oil-Fired Steam Boilers – Boiler Manual

7 Connect oil piping

General oil piping requirements

• Locationandinstallationofoiltanks,oilpipingandburners

must follow:

• NFPA31,latestedition-StandardfortheInstallationof

Oil-BurningEquipment.

• Localcodesandregulations.

• Informationprovidedwithburnerandfuelpump.

• Ifanypartoffueloiltankisabovelevelofburner,ananti-siphon

device installation is highly recommended to prevent flow of

oil in case of oil line break.

• Supportoillinesasrequiredbycodes.

• Maketankconnectionswithswingjointsorcoppertubingto

preventbreakingincasethetanksettles.Makeswingjoints

so they will tighten as tank settles. Non-hardening pipe joint

compounds should be used on all threads.

DonotuseTeontapeasanoilpipesealant.Itcan

causevalvestofail,creatinghazards.Donotuse

compression fittings, only flare fittings. Failure to

comply could result in severe personal injury, death

or substantial property damage from oil leakage

and/orrehazard.

• Undergroundpipemustberuninacasingtopreventoilleaking

into ground or under floor. Check local codes for information.

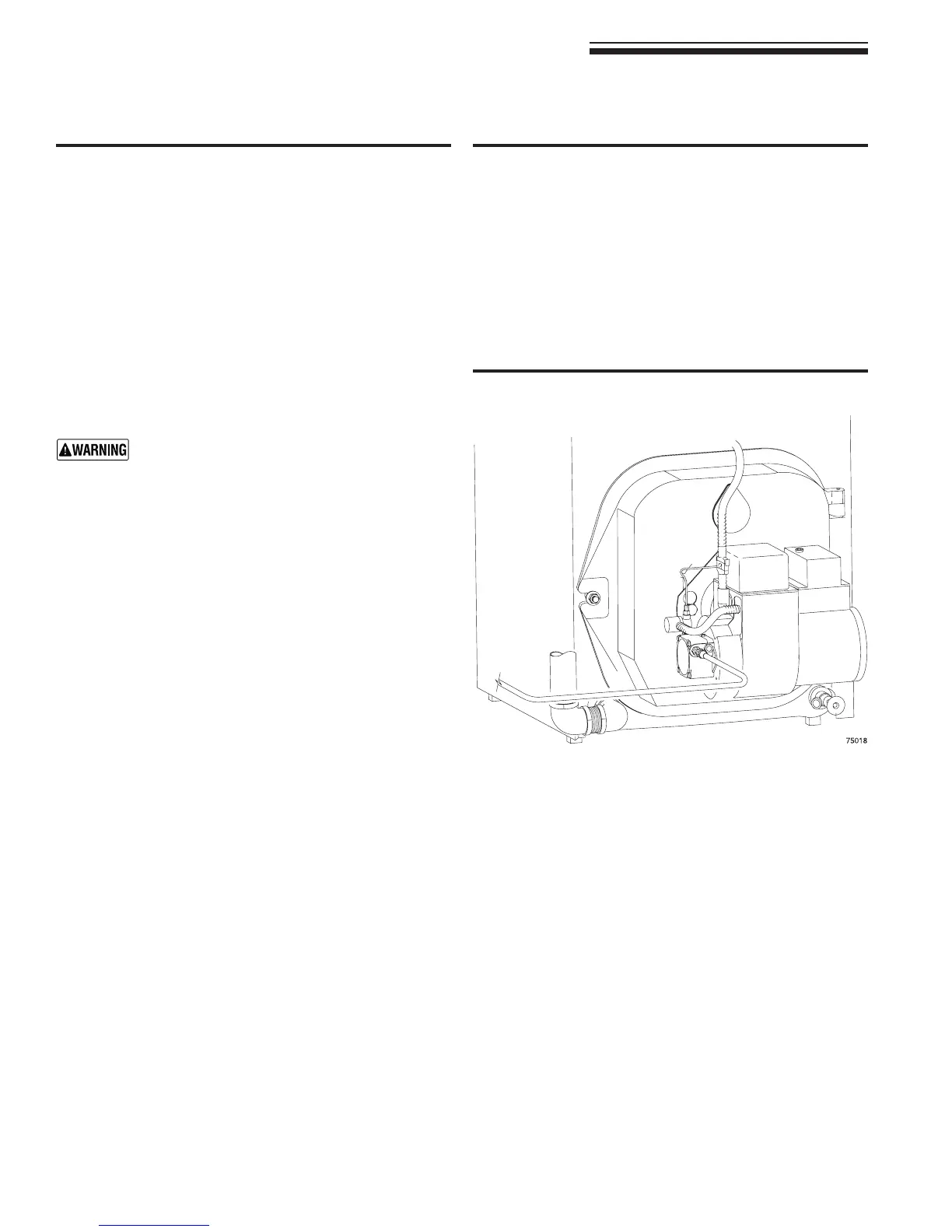

Oil piping connection at burner

• SeeFigure 13 fortypical oilconnectionatburner, allowing

burner mounting door to swing open completely for servicing.

• Connectoillinetoburnerusingaretting(Figure13).

• Seelocalcodesforappropriatearrangementandpiping of

filter, control valves, etc. connecting to oil tank.

• Refertoburnermanualforoilsystemrequirements.Verifythat

suctionliftdoesnotexceedstatedlimit.Whereliftexceeds

limit for a one-pipe system, use a two-pipe system as directed

in burner manual.

Figure 13 Oil piping connection to burner, typical

Loading...

Loading...