OSB

Series 2 Oil-Fired Steam Boilers – Boiler Manual

Part Number 550-110-772/0816 7

General

If installation is to comply with special codes, additional limit

controlsmayberequired.Ifinstallingaoat-typelowwatercutoff,

use only those devices that can be connected to the boiler gauge

glass tappings. Refer to the wiring diagrams on page 13 for correct

wiring location of additional limit controls.

Relief valve

Installboilerreliefvalveinthe¾”tappinginthebackoftheboiler,

usingthe¾”nippleandelbowsuppliedinthebagwithreliefvalve.

Follow the steps below to avoid potential severe

personal injury, death or substantial property damage.

• When installing the relief valve,ensure that all

connections, including the valve inlet, are clean and

free from any foreign matter.

• Mountthereliefvalveonlyintheverticalposition,

directly connected to the tapping designated in the

manual on top of the boiler.

• Usepipecompoundsparingly,ortape,onexternal

threads only.

• Donotuseapipewrench!Usepropertypeandsize

wrench on wrench pads only.

During operation, this valve may discharge large

amounts of steam and/or hot water. Therefore, to

reduce the potential for bodily injury and property

damage,adischargelineMUSTbeinstalledthat:

• Is connected from the outlet to a safepoint of

discharge with no intervening valve.

• Allowscompletedrainageofboththevalveandthe

discharge line.

• Isindependentlysupportedandsecurelyanchored

so as to avoid applied stress as possible.

• Terminatesfreelytoatmospherewhereanydischarge

willbeclearlyvisibleandisatnoriskoffreezing.

• Is,overitsentirelength,ofapipesizeequaltoor

greater than that of the valve outlet.

Use only schedule 40 metal pipe for discharge.

(Do not use schedule 80, extra strong or double

strongpipeorconnections.)DONOTCAP,PLUG

OROTHERWISEOBSTRUCTDISCHARGEPIPE

OUTLET!Ifdischargeispipedupward,acondensate

drain must be provided in the elbow below the vertical

pipe to prevent condensate from returning into the

valve. Failure to comply with these instructions will

cause a dangerous spray of hot water and steam

that would cause severe personal injury or death.

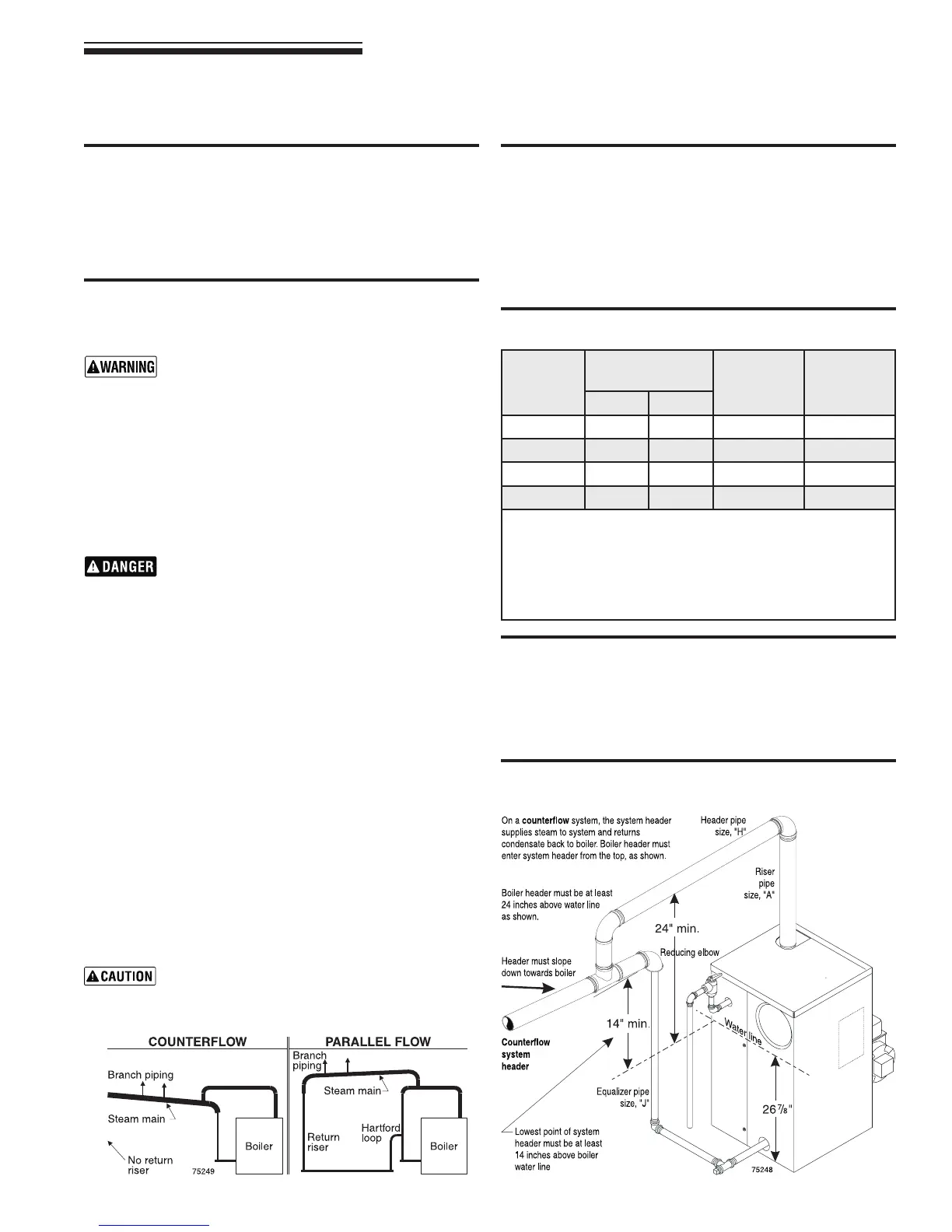

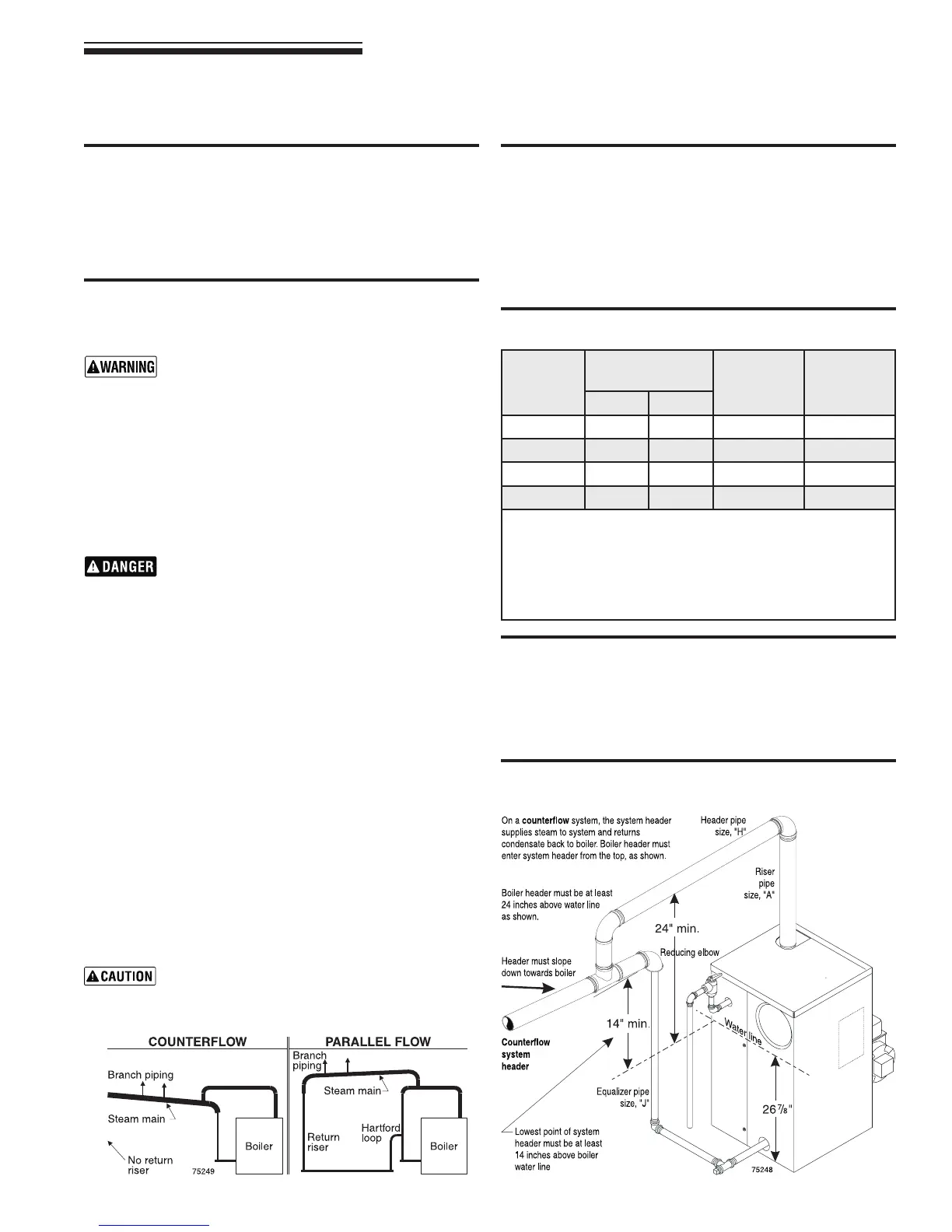

Connecting to counterflow piping

ApplytherecommendedpipinginFigures4through7onlywhen

connecting to a parallel-flow system. When connecting to a

counterflow system, the boiler steam supply must connect into the

top of the counterflow system header, as shown in Figure 3, below.

Figure 3 Connection to counterow steam piping only

(for parallel ow systems, see page 8)

The piping in Figure 3 applies only to the special

case of counterflow steam systems. Refer to page

8 for parallel flow steam systems. See below.

4 Connect steam piping

Table 4 Recommended pipe sizing

Near-boiler piping

SeeFigures4and5,page8,forrecommendedpipingofboilersizes

OSB-3,-4and-5.SeeFigures6and7,page8,forrecommended

pipingofOSB-6boilers.Thesepipingrecommendationsapplyonly

to connections to parallel-flow one-pipe and two-pipe systems.

For counterflow systems, connect boiler supply and return to

counterflow system header as shown in Figure 3, below. Table 4,

below,givesrecommendedpipesizes.

Boiler

model

number

Riser

pipe size

(Note 1)

Header

pipe size

“H”

(Note 2)

Equalize

pipe size

“J”

A B

OSB-3 2-1/2” --- 2-1/2” 1-1/2”

OSB-4 2-1/2” --- 2-1/2” 1-1/2”

OSB-5 2-1/2” --- 3” 1-1/2”

OSB-6 2-1/2” 2-1/2” 4” 1-1/2”

Notes:

1. Based on ASHRAE Fundamentals Handbook recommendations,

allowing ½ oz. pressure drop at 0 psig.

2. Based on ASHRAE Fundamentals Handbook recommendations,

allowing 2 oz. pressure drop per 100 feet of pipe at 3.5 psig.

Maintain minimum 24” height from waterline to bottom of header.

Note Figure 3, showing the special connection required to a

counterow system.

Loading...

Loading...