OSB

Series 2 Oil-Fired Steam Boilers – Boiler Manual

Part Number 550-110-772/0816 9

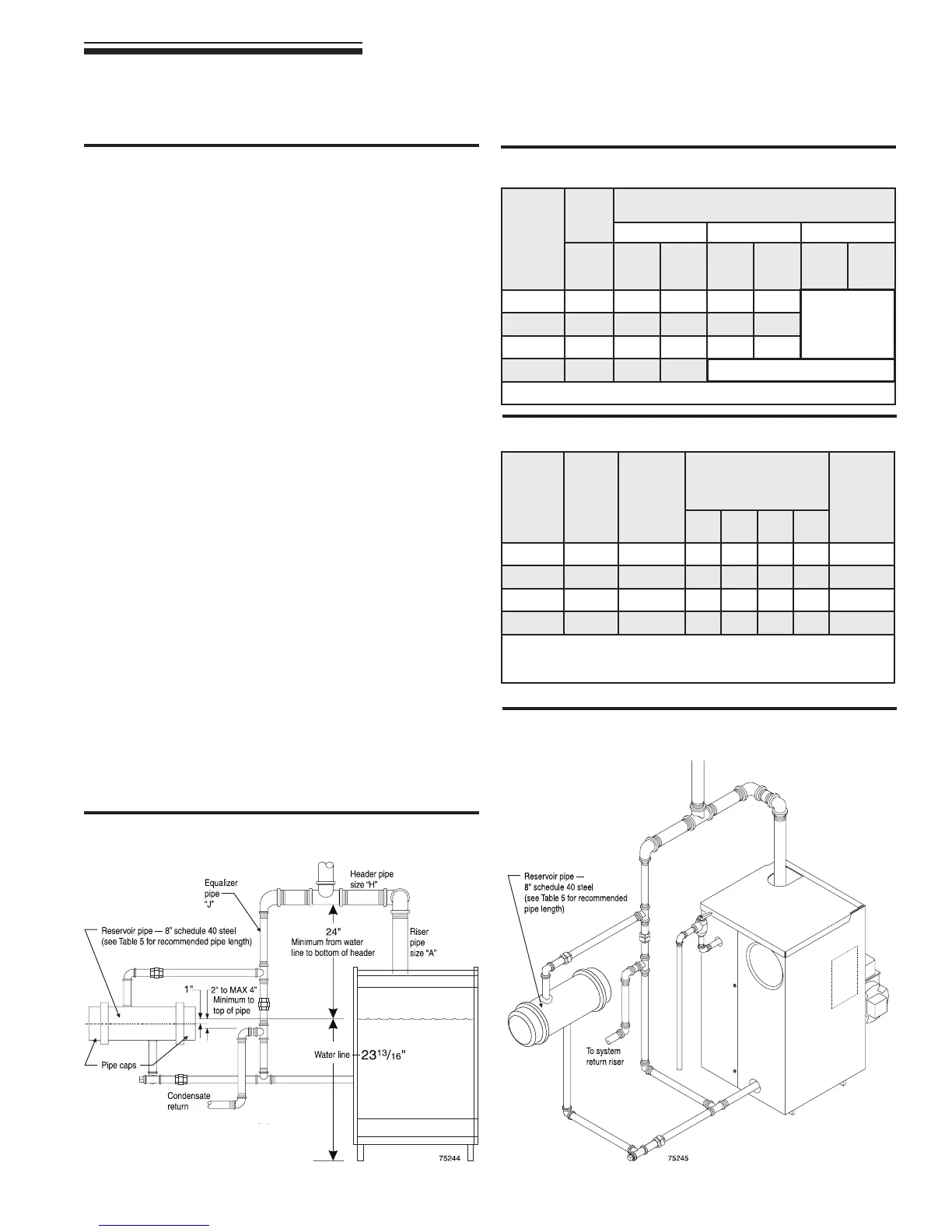

Figure 8 Recommended piping for parallel-ow

systems with optional reservoir pipe

Modernsteamboilersaredesignedtosteamforlesstimethan

older, larger boilers. When replacing an older steam boiler the

system condensate return time may be longer than the steaming

time. This could cause the following problems:

1. Boilers fitted with an automatic water feed could overfill.

2. Unitsttedwithonlyalowwatercutoffwouldshutdownand

cycle while waiting for condensate to return.

Following is a simple method for determining whether or not

a reservoir pipe is required to lengthen steaming time for a

residential installation:

1. Disconnectcondensatereturnlineatexistingboiler.

2. Heatboilerandallowtosteamfor10minutes.Turnoffboiler.

3. Measurelengthoftimefromwhenboilerstartedtosteamto

when condensate begins to return through condensate line.

4. Measurelengthoftimefromwhencondensatebeginstoreturn

to when it stops returning. Divide this time by 2.

5. Addtimemeasuredinstep3totimecalculatedinstep4.This

sum is the average time required for condensate to return to

the boiler.

6. Ifthistotaltimeis10minutesorless,noreservoirpipeisneeded.

If total time for condensate to return to boiler (from step 5) is

morethan10minutes,areservoirpipe(orboilerfeedsystem)is

recommended. See Table 5, this page, for suggested reservoir

pipesize.InstallasshowninFigures8and9,below.

Forlargersystems(asnotedinTable5),useaboilerfeedsystem

withacondensatetankandfeedpump.Youwillhavetoinstalla

low water cutoff/pump control on the boiler to operate the pump.

See“Lowwatercutoffs”onpage20andFigure18onpage26.

UseTable6tosizeboilerfeedsystems.(Theuseofacombination

condensate tank and float-controlled condensate return pump

is not recommended. These devices do not supply water to the

boiler on demand from the boiler, and cannot compensate for long

condensatereturntimes.)

For most residential installations a reservoir pipe may be all that

is necessary to ensure proper operation.

Condensate return

Table 6 Boiler feed system sizing

Table 5 Reservoir pipe sizing

4 Connect steam piping continued

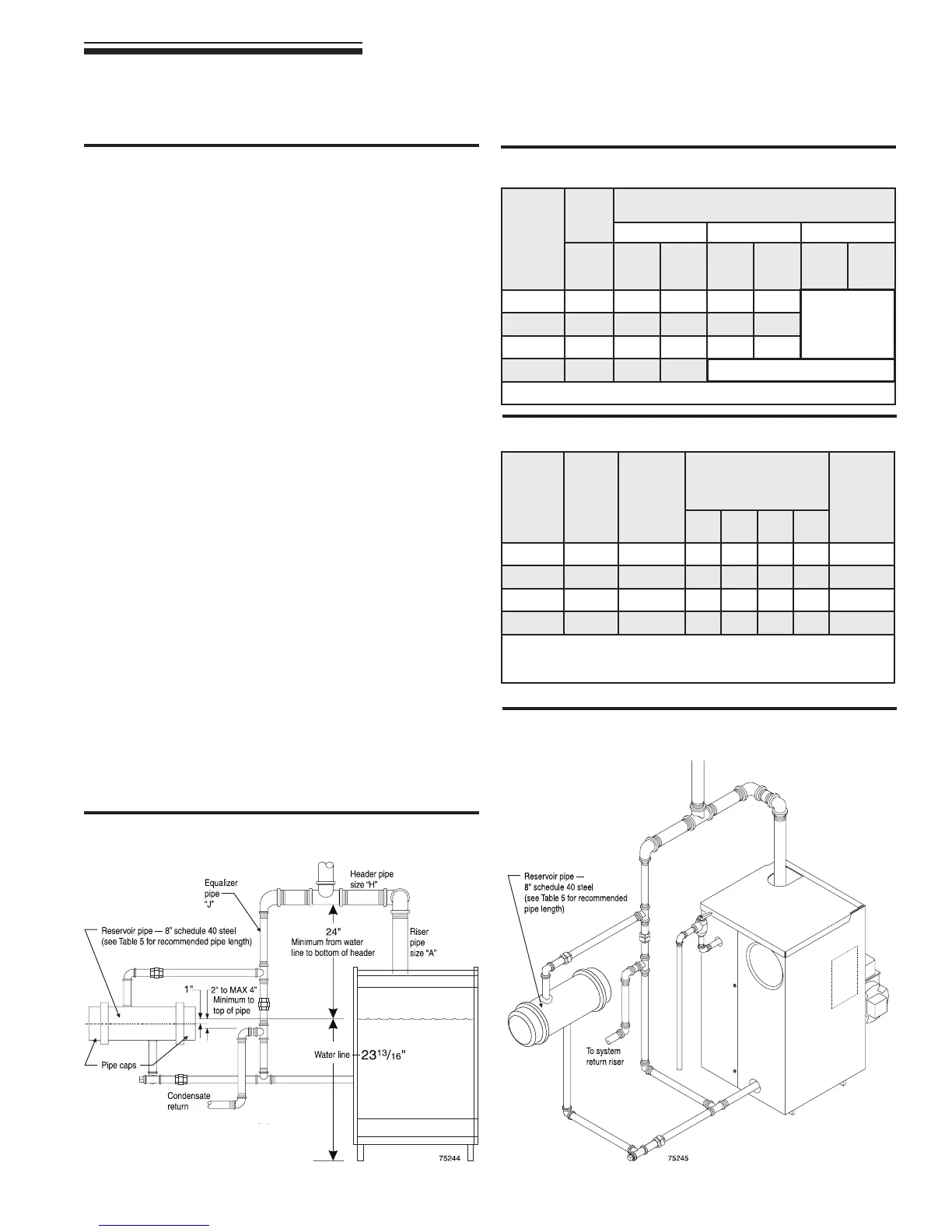

Figure 9 Recommended piping for parallel-ow

systems with optional reservoir pipe

Boiler

model

number

Net

output

Time from initial steaming to average condensate return

(boiler steaming capacity based on 970 Btu per pound of steam)

15 minutes 20 minutes 30 minutes

Steam

MBH

gallons

Pipe

length

(feet)

gallons

Pipe

length

(feet)

gallons

Pipe

length

(feet)

OSB-3 114 1 1 2 2

Use boiler feed

system

OSB-4 144 1-1/4 1-1/4 2-1/2 2-1/4

OSB-5 174 1-1/2 1-1/2 3 2-1/2

OSB-6 210 1-3/4 1-3/4 Use boiler feed system

Designed full capacity steaming time of modern boilers is 10 minutes.

Boiler

model

number

Net

output

(pounds

steam

per

hours)

Condensate

(gallons per

hours)

Minimum condensate

receiver capacity gallons

for steaming times

(minutes) of: (note 1)

Suggested

feed pump

capacity

(GPM @

15 PSI)

(note 2)

15

min.

30

min.

45

min.

60

min.

OSB-3 118 14 4 8 13 17 0.5

OSB-4 148 18 5 11 16 21 0.6

OSB-5 179 22 6 13 19 26 0.7

OSB-6 216 26 8 16 23 31 0.8

Notes:

1. Maximum time to when condensate returns to boiler.

2. If pump exceeds capacity shown, pump can be throttled with globe or ball valve.

Loading...

Loading...