19

7.2 Cleaning the liner

►

Clean the liner as described in the liner instructions for use.

7.3 Cleaning the vacuum pump

> Required materials: 30ml to 60ml distilled water, vessel

1) Fill distilled water into the prosthetic socket.

Alternatively, a residual limb sock can be soaked with distilled water to flush the vacuum

pump while walking.

2) Position the vessel under the outlet of the vacuum pump.

3) Alternately load and unload the prosthesis to pump all the water through the vacuum system.

4) Clean and dry the interior surface of the prosthetic socket.

8 Maintenance

CAUTION

Failure to follow the maintenance instructions

Risk of injuries due to changes in or loss of functionality and damage to the product

►

Observe the following maintenance instructions.

►

A visual inspection and functional test of the prosthetic components should be performed

after the first 30days of use.

►

Inspect the entire prosthesis for wear during normal consultations.

►

Conduct annual safety inspections.

►

Check the condition of the functional ring as part of each inspection. If the user frequently

compresses the functional ring to the stop while walking, or if the functional ring exhibits vis

ible damage, replace the functional ring (see page20).

8.1 Checking for leaks

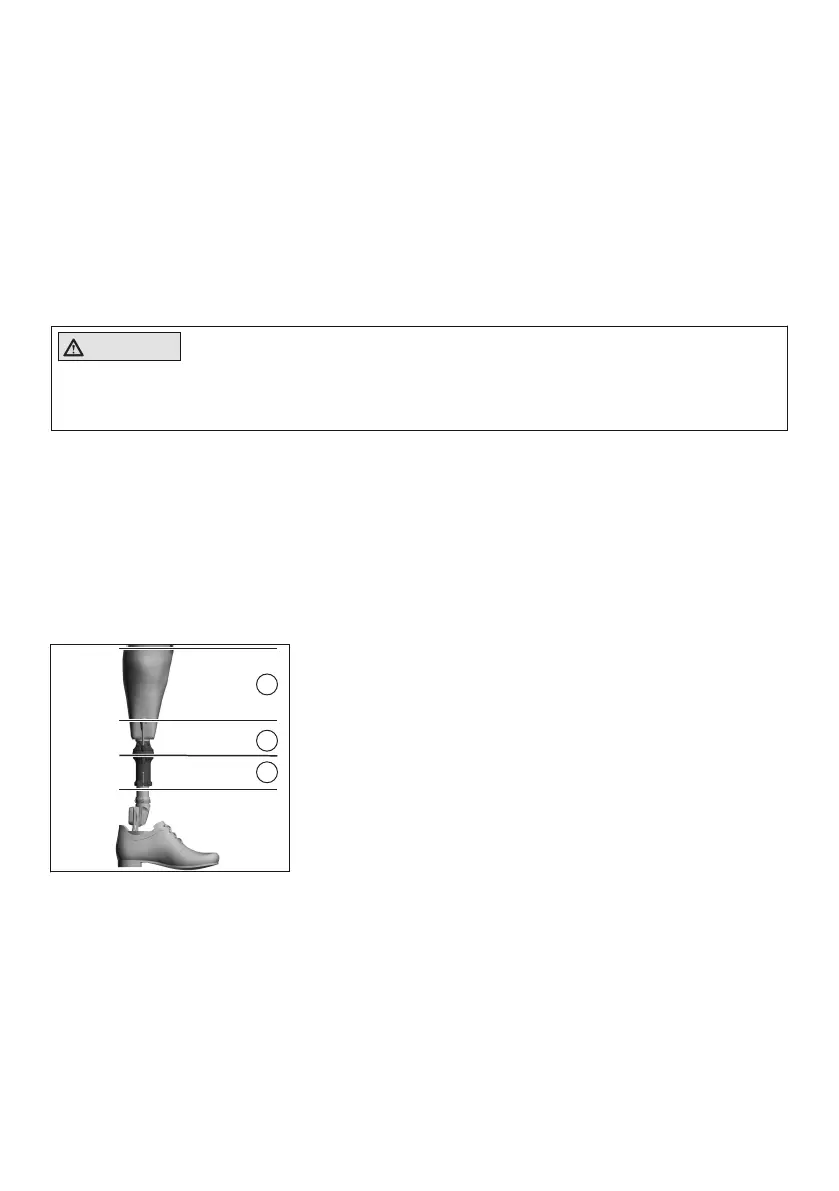

This section gives a methodical troubleshooting procedure for when the vacuum system leaks.

To check for leaks, the prosthesis is divided into areas.

• Area 1: Prosthetic socket and sealing sleeve

• Area 2: Socket connector and connection to the

vacuum pump

• Area 3: Vacuum pump

Checking area 1

First check the donning process and the sealing sleeve. No pressure gauge is needed. The vacu

um suctions the sealing sleeve against the socket brim. The socket brim is clearly visible under

the sealing sleeve during the stance phase. If no vacuum is generated or the vacuum decreases,

this can be identified on the sealing sleeve.

• Ask the user to put on the prosthesis. Check the process to exclude errors during donning.

• Get the user to walk in order to build up a vacuum. Get the user to stand and check whether

the vacuum is maintained.

• If the vacuum is not maintained: Replace the sealing sleeve with a new one.

Loading...

Loading...