15

• Pumped fluid changes state in contact

with air, i.e. crystallizes, forms a film,

dries out or precipitates solids. The flush

dissolves and rinses away the small

amount of residue which could build up on

the edges of the seal faces.

• Pumped fluid is close to its boiling point,

e.g. water over 80°C (175°F). The

flushing fluid is used to cool the seal faces.

• Pumped fluid is temperature sensitive and

evaporates when heated by the shearing

action of the seal faces. The flushing fluid

is used to cool the seal faces.

• Pump may run “dry”, i.e. no liquid in

pump chamber for very short periods.

• Pump is under high vacuum.

• A low pressure sterile barrier is required.

A low-pressure flushing fluid system must

be installed as follows:

• Liquid must be compatible with the

pumped fluid; water is the most

commonly used liquid.

• Pressure shall typically be 0.5 bar (7 psi)

gauge. Maximum of 1.0bar (14.5 psi)

gauge.

• Temperature shall be maximum of 70ºC

(160ºF) for water, less for volatile liquids

(minimum 20ºC (68ºF) below boiling point

of liquid).

• Flow rate shall preferably be 2 to 3

litres/min. (0.5 to 0.75 US gal/min) per

seal.

• Flush fluid should be connected to enter

at the lowest point on the seal housing

and flow out at the highest point to vent

air pockets.

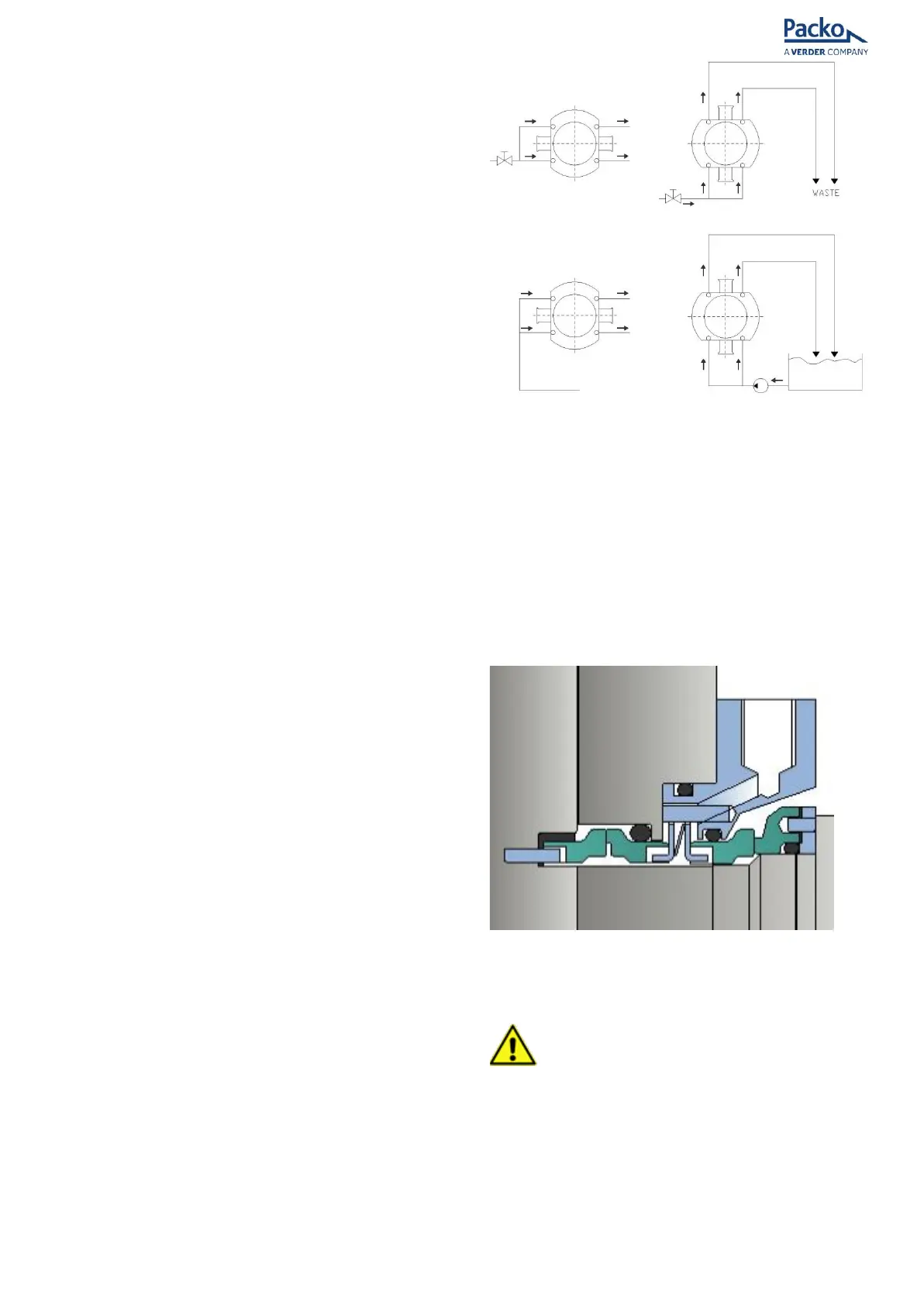

• Pipework should be as shown in the

diagram (Figure 11).

Figure 11 - Suggested low pressure flushing system

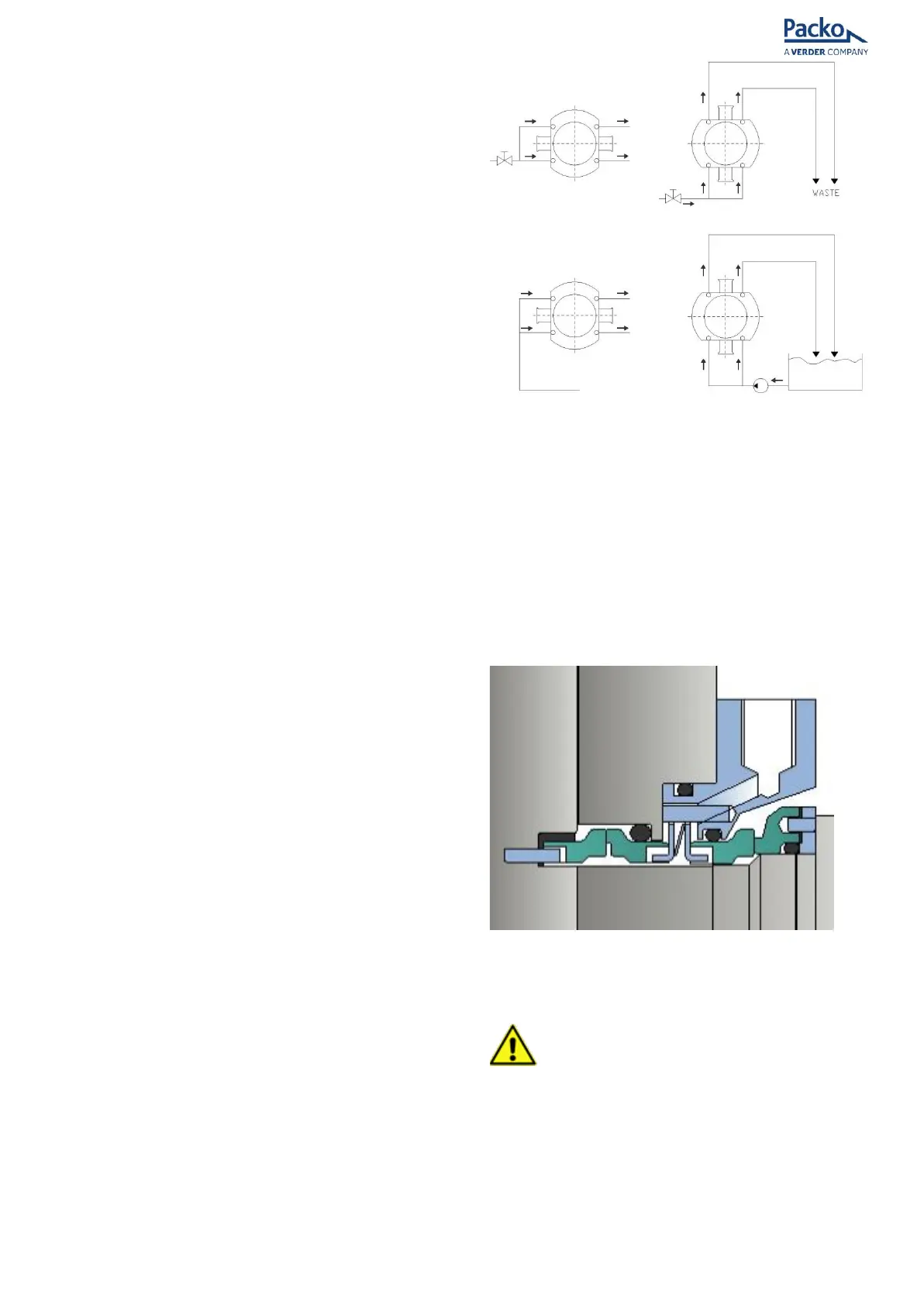

The Double Mechanical Seals fitted to HP &

LH pumps provide the facility to contain a high

pressure fluid behind the primary seal. This allows

the pump to be used for applications where the

single seal is unsuitable.

Double seals code D are run with a fluid between

the primary and secondary mechanical seals to

form a barrier between the pump and the

atmosphere. (Figure 12)

Figure 12 - Double mechanical seal (Size 4-8)

Double Mechanical Seal with a low pressure

liquid flush when:

ATTENTION

• The pumped fluid is toxic or hazardous

and must not escape from the pump even

in minute quantities.

• The system can be installed as in figure 12,

but must be capable of withstanding the

Loading...

Loading...