16

full pressure within the pumped fluid pipe

system.

Double Mechanical Seal with a high

pressure liquid flush when:

• The pumped fluid has no lubricating

properties and cannot be allowed onto

seal faces

• The pumped fluid is highly viscous, i.e.

over 150,000 cP.

• A high pressure sterile liquid barrier is

required.

When the double seal is used with a high

pressure liquid flush for the reasons described

above, a flushing system must be installed as

follows:

• The flushing liquid used must itself be

compatible with the pumped fluid and

must itself not require a complex seal, i.e.

must be non-hazardous, non-abrasive and

lubricating.

• Flush liquid must be at a pressure of 1 bar

(15psi) above the discharge pressure of

the pump and should flow at 35 to 55

litres/hour (10 to 15 US gal/hour) per seal.

• Flush fluid should be connected to flow in

at the lowest point on the seal housing

and out at the highest point to vent air

pockets.

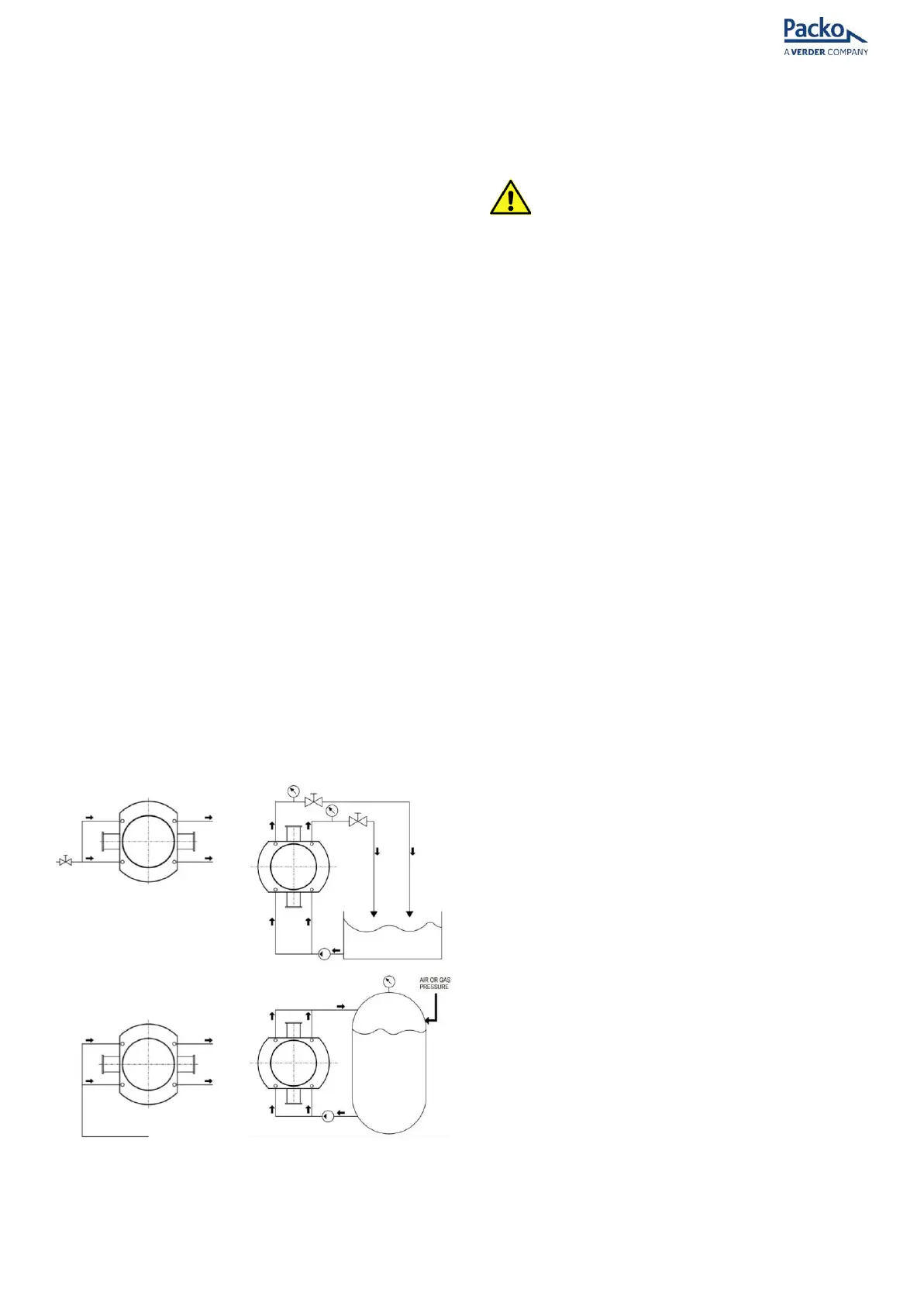

Refer to the drawing below for the suggested

liquid flush system (Figure 13).

Figure 13 - High pressure liquid supply for double seals

Double Mechanical Seal with steam when:

No bacteria or contamination can be allowed to

enter the pump, i.e. an aseptic system.

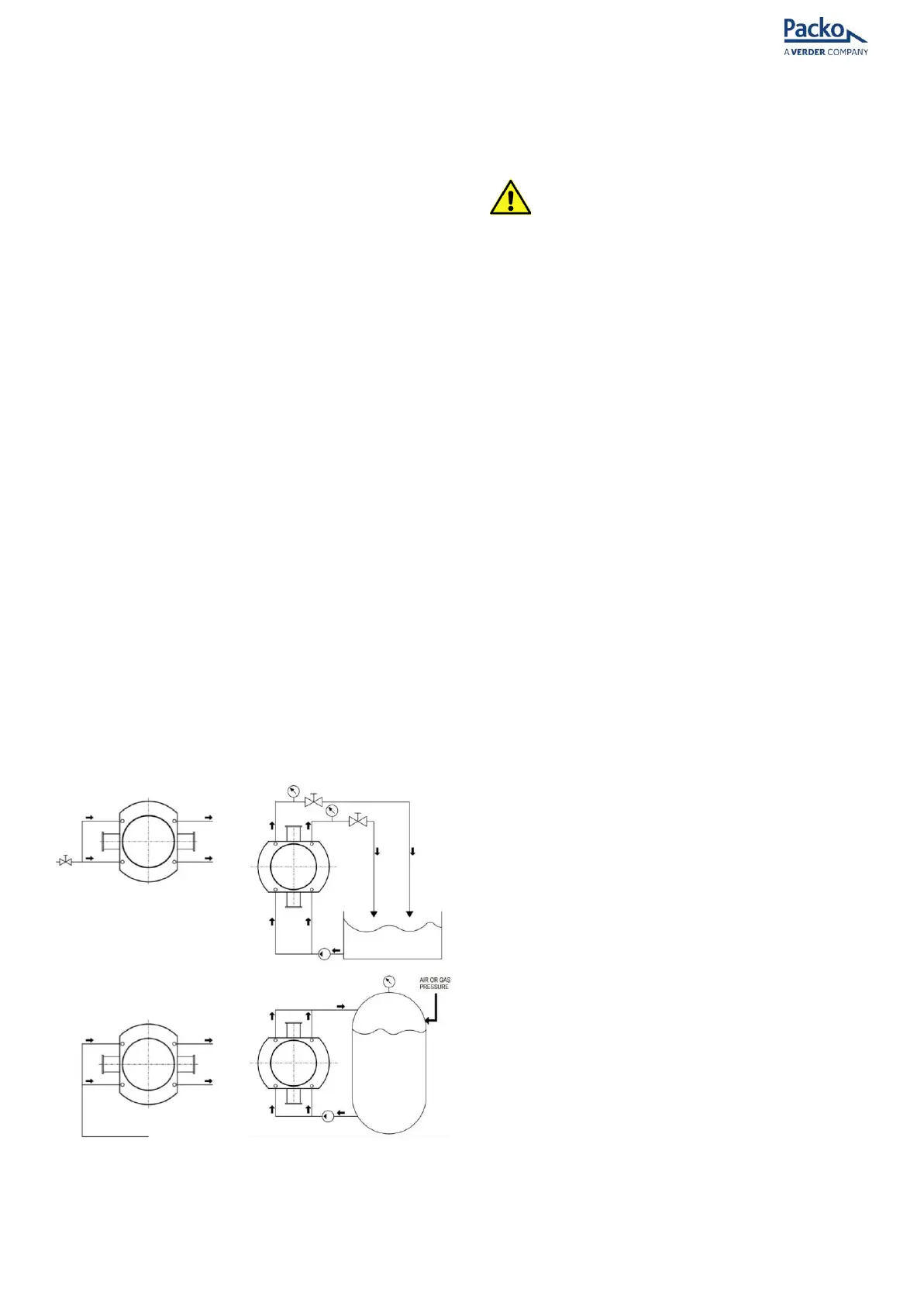

A steam barrier system must be installed as

follows:

ATTENTION

• Wherever possible, sterile liquid i.e. steam

condensate should be used as a flush.

Condensate should be connected to flow

in at the lowest point on the seal housing

and out at the highest point to vent air

pockets.

• Where steam is essential, great care must

be taken with the design of pipework,

steam traps and controls.

• Steam must be clean, filtered and wet, i.e.

not superheated.

• The pressure of steam should be as low as

possible consistent with the desired

temperature.

• Steam should be connected in at the

highest point on the seal housing and out

at the lowest point to allow any

condensate to drain from the lowest point.

• Refer to Figure 14 for suggested steam

connection.

Loading...

Loading...