25

Figure 21 - Seal seat removal hooked end

• Push back the O-ring with the end of the tool

and rotate the tool by 90 degrees, until the

hooked end locks in position behind the seal

seat. (Figure 20 & 24)

• Working the tool gently around the

circumference of the seal, carefully pull the

seal face out.

• Take great care not to scratch or damage the

smooth face of the seal.

• Keep each seal with its respective shaft to

ensure correct mating of the seal faces on re-

assembly.

• The joint ring (83) may come out with the

seal face. If not, then remove it from the

rotor case bore and keep it together with the

seal face.

• You may wish to label the components.

Note: static seal seats can also be accessed from

the back of the rotor case after removing the

rotor case and seal housings (see 6.6 SEAL

HOUSINGS).

• Only remove the rotary seal seat (80) from

the back of the rotor (56) if you intend to fit a

new seal or L cup rubber (83). Gently prise

out the seat from the rotor using two soft

levers to avoid scratching rotor and damaging

seal face. (Figure 22).

Figure 22 - Seal removal from rotor

HP32 & HP34 Pumps

ATTENTION

Note: Double mechanical shaft seals are not

available on the HP3 size pumps

• Pull the static faces (80) from their bores in

the rotor case (51), removing the joint ring

(83) with each seal face. Take care not to

scratch or damage the smooth face of the

seal.

• If you intend to re-use these faces keep each

seal with its respective shaft to ensure correct

mating of mating of seal faces on reassembly

- you may wish to label the components.

• Only remove the seal seat from the back of

the rotor (56 & 57) if you intend to fit a new

seal or cup rubber (83).

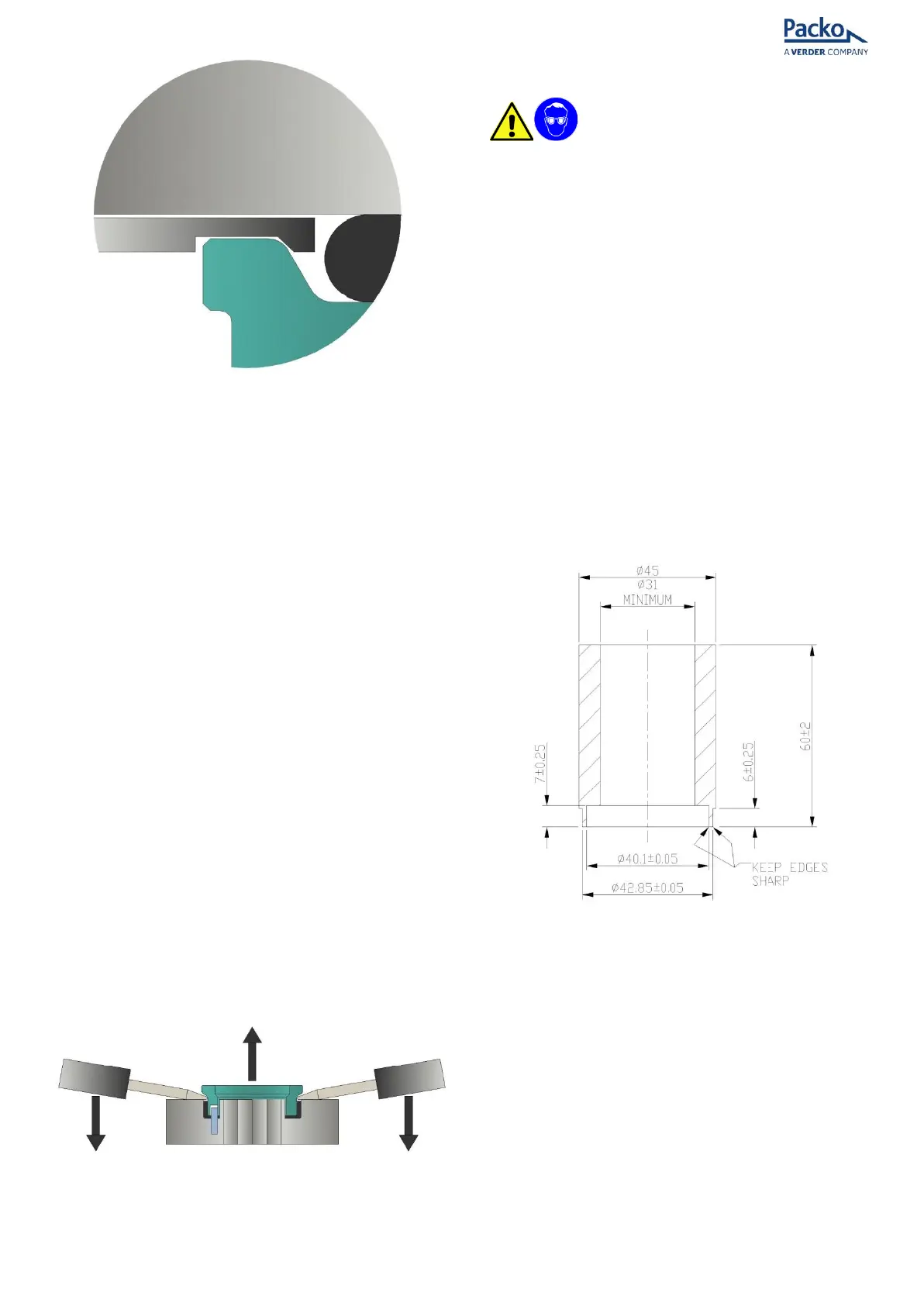

To remove the seal seat from the back of the

rotor a special tool is required. This tool needs to

be manufactured to the dimensions shown in

Figure 23.

Figure 23 - Sleeve dimension

• Press the sleeve down onto the visible edge of

the cup rubber. This will force the rubber

down into the seal bore in the rotor. The seal

face will be pushed out of its bore.

Do not lever out the seal face with screwdrivers

or similar tools as seal materials are brittle and

are easily damaged or broken.

If the seal face is to be re-used, note which way

up it was fitted - seal faces are not reversible.

Fitting Mechanical Seals:

Loading...

Loading...