26

Note: if refitting previously used seal faces

ensure that rotary and static faces are in their

original pairs.

HP4-6

ATTENTION

Fit the seal face with the narrow face track into

the rotor case. The seal face with the wide face

track should be fitted into the rotor.

• Fit the O-ring (83) to the static primary seal

face and lubricate the bore in the rotor case

with a suitable lubricant compatible with the

pumped fluid and the elastomer.

• DO NOT use mineral-oil based lubricants on

EPDM joints.

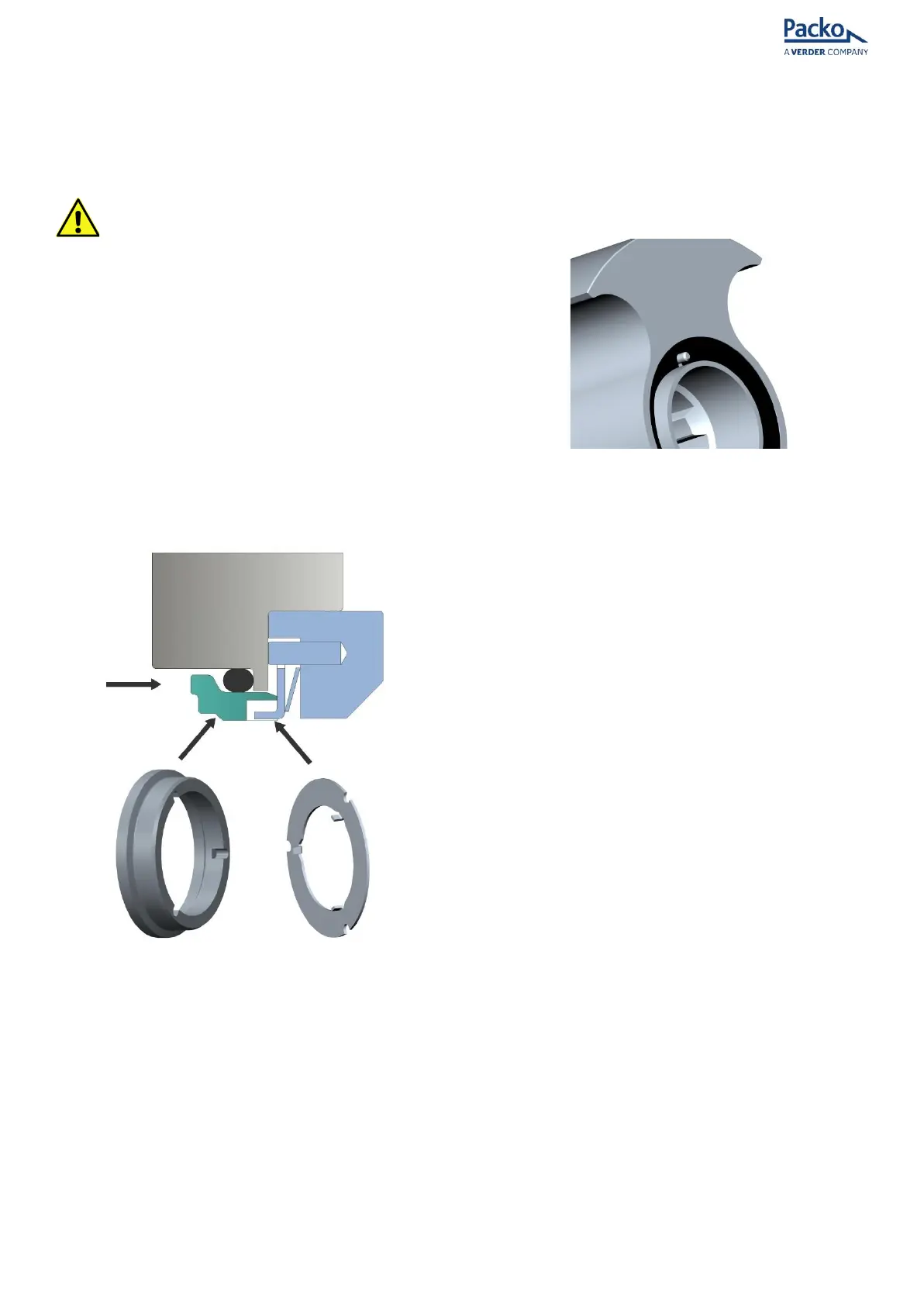

• Align slots in the seal face with tabs of drive

plate in the seal housing; a small cut-out is

provided so one drive tab can be seen (Figure

24).

Figure 24 - Fitting stationary seat

• Push each seal seat in straight; when

correctly fitted, seal seats should slide freely

against the resistance of their springs.

Undue pressure is not required or recommended

as seals are precision components. Be sure not to

damage the O-ring (83), if difficulty is

experienced put the O-ring into the rotor case

bore then push the seal seat into the bore.

Note: if the rotor case has been removed (see

6.7 ROTOR CASE), static seal seats should be

inserted into the rotor case, before mounting on

to bearing housing.

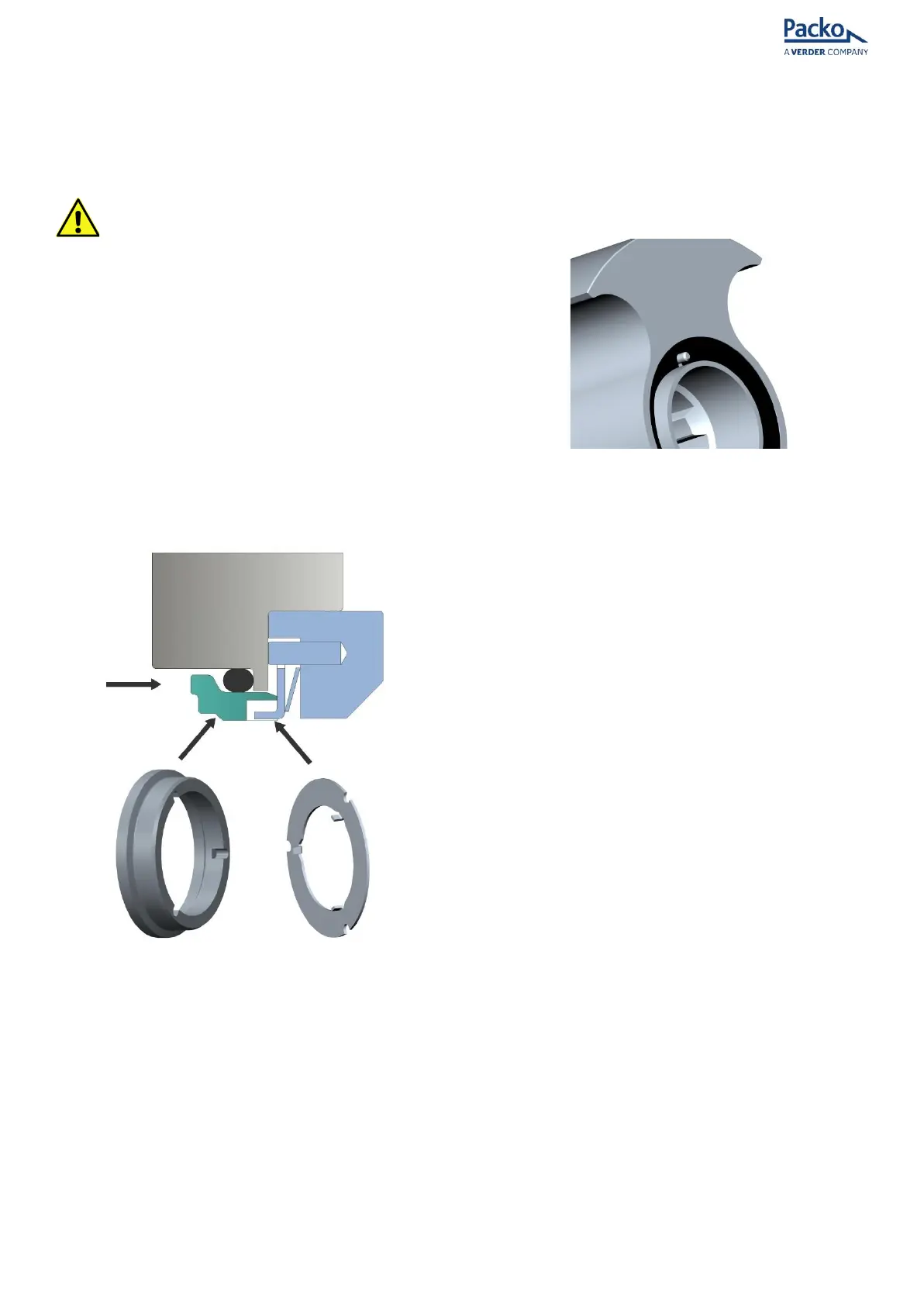

• To fit the seal seat to the rotor (56), first

insert L cup rubber (83) into the rotor (DO

NOT lubricate), ensure alignment with the

drive pin. (Figure 25).

Figure 25 – Align the L cup to the rotor drive pin

• If the PTFE trim is fitted, insert the rubber

washer first followed by the PTFE sleeve. Note

that the sleeve is slightly tapered and will be

easier to fit if the narrow side is inserted first.

Then lubricate the outside diameter of the

seal seat.

• Align the rotor drive pin with one of the three

slots in seal seat.

• Engage the leading edge of the seal seat into

the cup rubber or PTFE sleeve. Push down

evenly until the seal seat rests squarely on

the bottom of the seal bore in the rotor.

• DO NOT damage the seat face.

• When correctly fitted, the seat is parallel with

the back face of the rotor and must not be

tilted. Any “run-out” of the seat will cause

leakage of the seal.

• Assembly of the seal is now complete.

• Carefully clean all the seal faces with a soft

lint free cloth and to remove all dust and

grease.

• It may be necessary to use a compatible

solvent to remove oil or grease.

• It is not normally necessary to remove the

seal housings (86) from the back of the rotor

case except to check the condition of the

springs (82) and drive plates (81).

• If re-fitting the seal housings, align the 3 slots

in outer edge of drive plate with the 3 pins.

When fitted, ensure the drive plate can slide

freely against the spring pressure. (see 6.6

SEAL HOUSINGS)

HP3 size pumps:

Loading...

Loading...