5

B1d.1

4/06

Supercedes 8/05

PACOPACO

PACOPACO

PACO

PUMPS

• Install a valve in the suction line to isolate the

pump during shutdown and maintenance.

• Valves should always be installed in positions

that avoid air pockets. Globe valves should

not be used,particularly when NPSH is critical.

• During pumping operation, valves on the suction line

must always be at FULL OPEN.

• Pressure gauges properly sized for the range of

operation, should be installed in gauge taps on the

pump suction and discharge nozzles.

I. DISCHARGE (OUTLET) PIPING

• Short discharge piping can be the same diameter as

the pump discharge opening. Longer piping should

be one or two sizes larger depending on length.

• Any high points in discharge piping may entrap air or

gas and thus retard pump operation. Air vents or

bleed valves as a means to release entrapped air

are recommended.

• An even gradient is best for long horizontal runs of

discharge piping.

• Install a valve near the pump discharge opening

to prime and start the pump. The discharge valve is

also used to isolate the pump during shutdown and

maintenance.

J. SHAFT SEALING-GENERAL COMMENTS

• PACO offers both mechanical seals and packed

stuffing boxes as a means to seal the shaft. Pumps

with stuffing boxes are normally packed before ship-

ment. If the pump is installed within 60 days after

shipment, the packing material will be in good condi-

tion for operation with a sufficient supply of lubrica-

tion. If the pump is stored for a longer period, it may

be necessary to repack the stuffing boxes (see Pack-

ing Replacement, Page 11, to repack the boxes).

• The stuffing box must be supplied at all times with a

source of clean, clear liquid to flush and lubricate the

packing (see Packing Replacement, Page 11). When

pumps are equipped with mechanical seals, no main-

tenance or adjustment is required.

K. GLAND ADJUSTMENT

• Make sure the flushing fluid lines are connected

and their valves are open. After pump start-up, with

the pump running,the packing gland should be ad-

justed to permit 40 or 60 drops per minute leakage,

this is required for shaft sleeve lubrication.

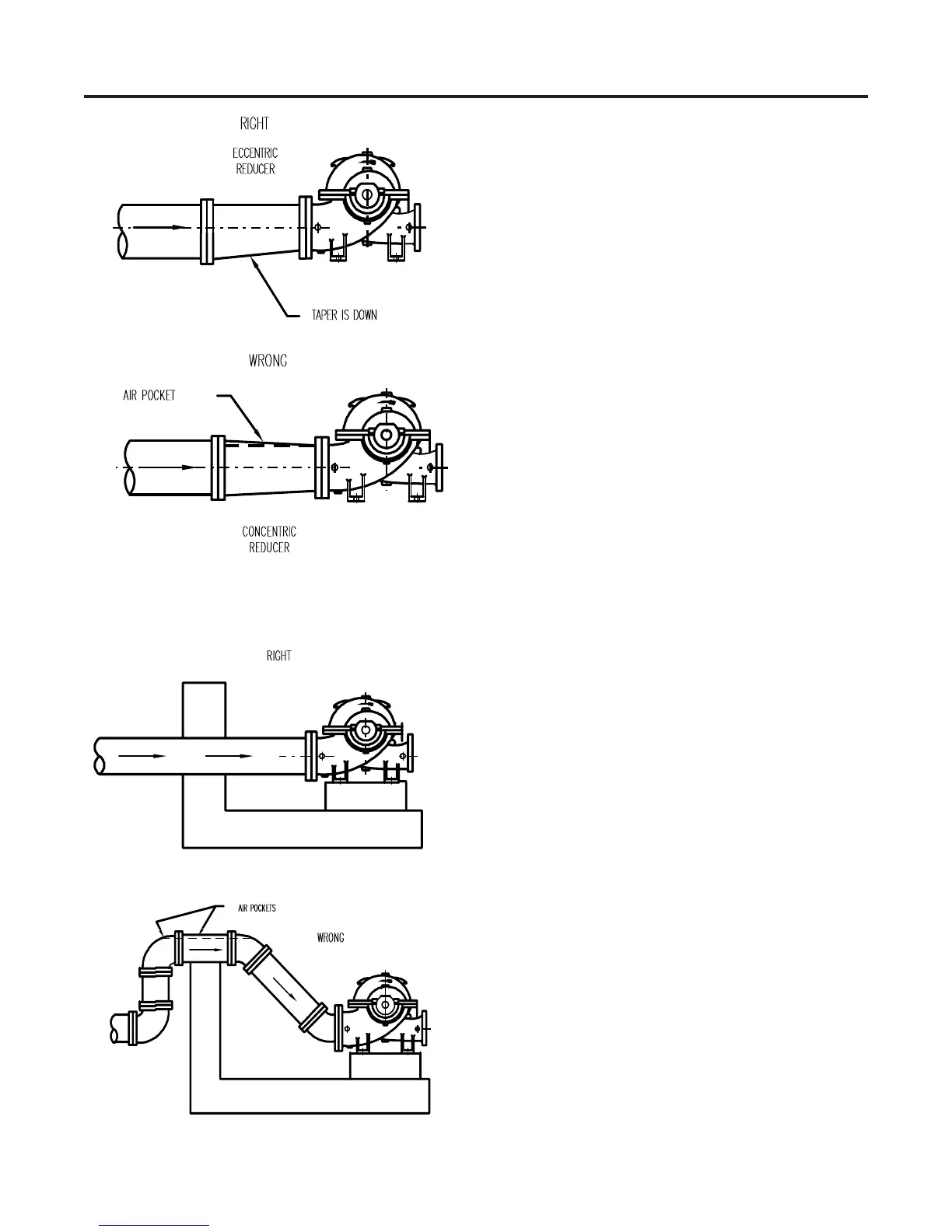

FIGURE 3a:

Suction Piping (Eccentric vs. Concentric).

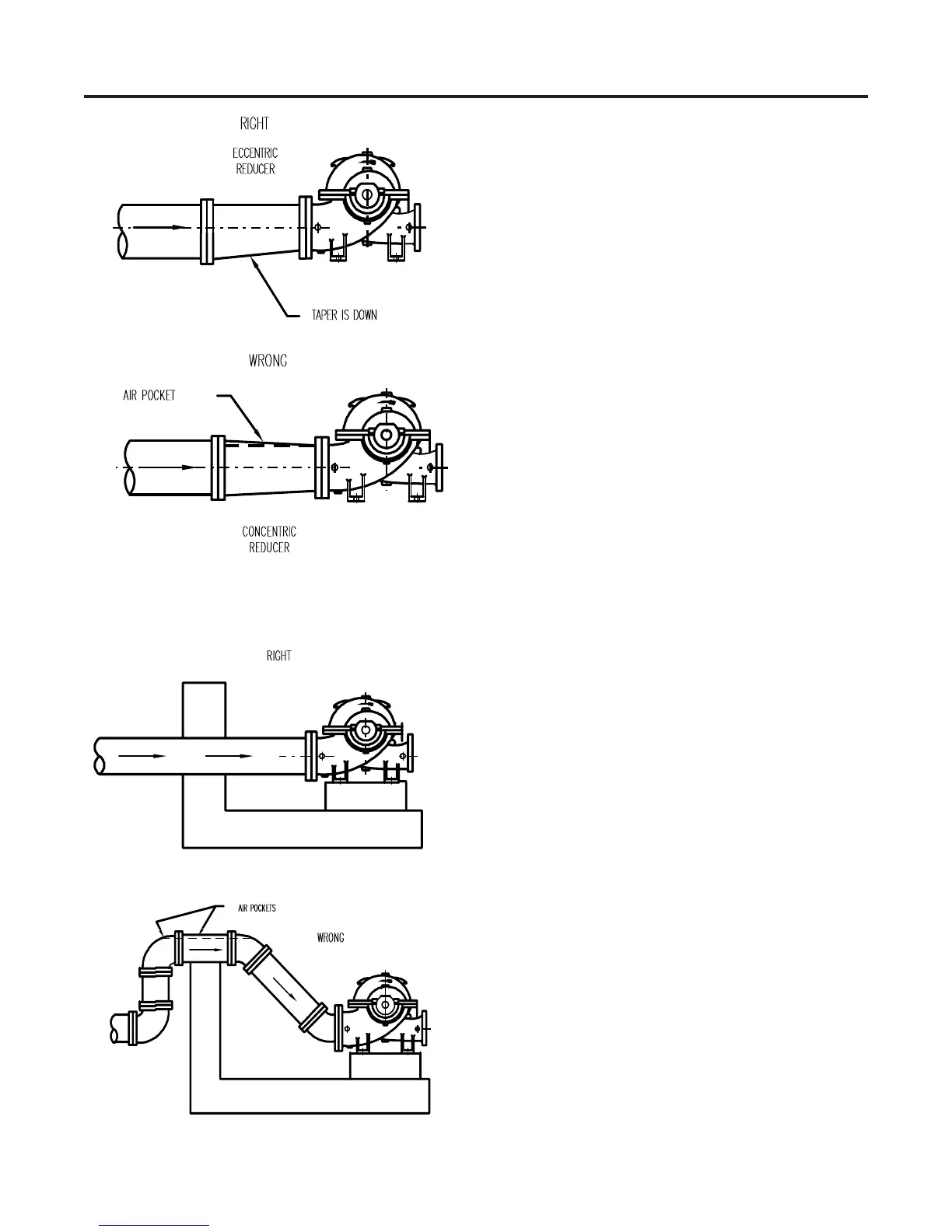

FIGURE 4a: Suction Piping (Avoid high points).

Loading...

Loading...