7

WARNING: This product can expose you to chemicals including lead or DEHP which are known to the state of California to cause cancer,

birth defects, and other reproductive harm. www.p65warnings.ca.gov

Catalog HY13-PMD600-SM/US

PGP/PGM 600 Series

Gear Pumps & Motors Service Manual

Disassembly Instructions

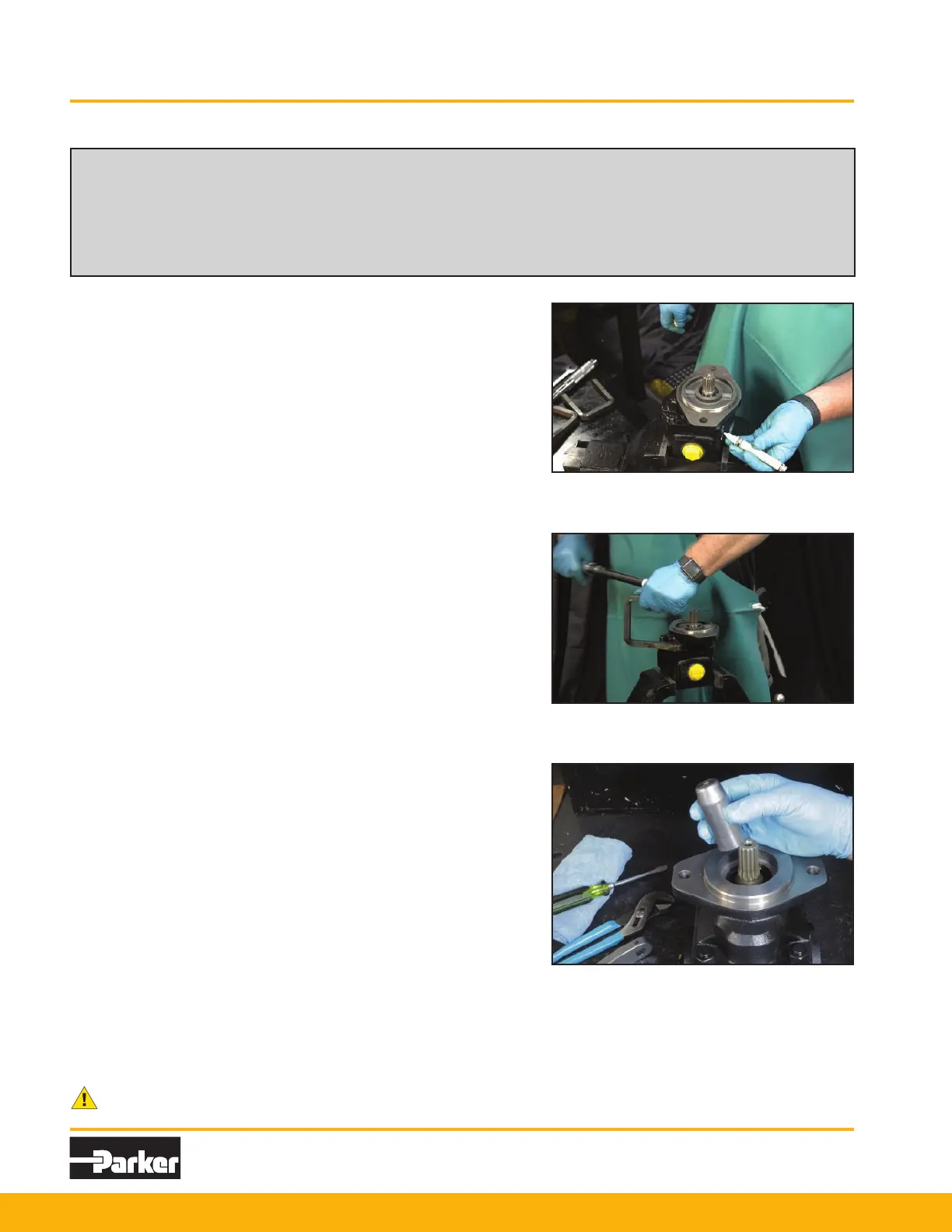

1) Place the pump in a vise with the drive gear pointing up

(Fig. 1). Match-mark all sections.

Be sure to align these marks when reassembling.

DO NOT GRIP ON OR NEAR ANY MACHINED

SURFACES DURING ASSEMBLY OR DISASSEMBLY.

Start Disassembly

CAUTION:

1. If prying off sections becomes necessary, take extreme care not to mar or damage machined surfaces. Excessive force

while prying can result in misalignment and seriously damage parts.

2. If parts are difcult to t during assembly, tap gently with a soft hammer. (Never use an iron hammer.)

3. Gears are closely matched, therefore they must be kept together as sets, avoid touching gear journals when removed

from a unit. Handle with care to avoid damage to the journals or teeth.

4. Never hammer bushings into bores. Use an arbor press.

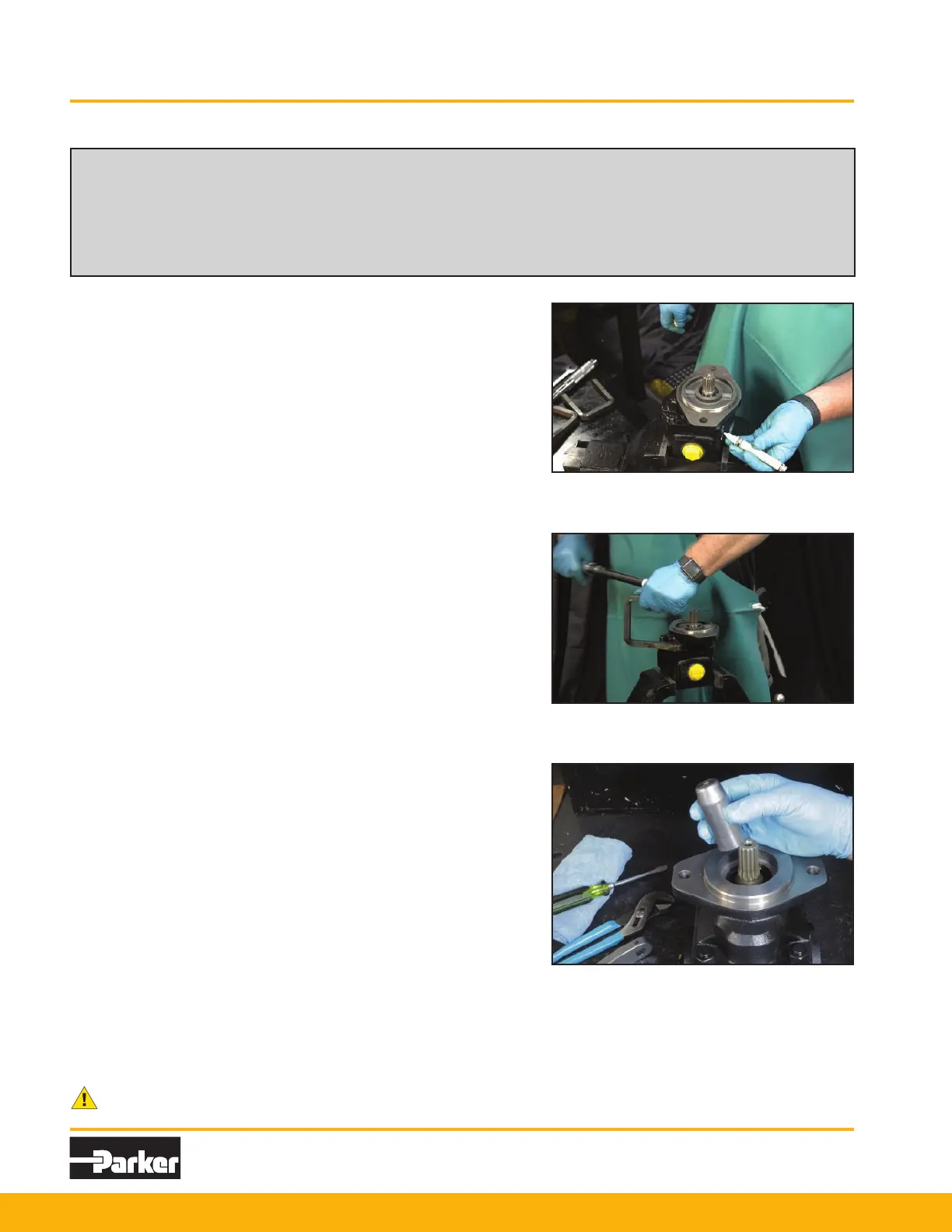

2) Remove four bolts and cap screws on single units

or the 4 hex nuts, studs and washers of multiple

units (Fig. 2).

Use a wrench to remove the 4 capscrews on

single units or the 4 hex nuts, studs and washers

of multiple units. The back bolts might need to be

loosened and the shaft end cover slightly lifted to

reach the back nuts all the way removed.

3) Place a seal guide over the seal before removing

the shaft end cover (Fig. 3). This step will help

avoid damaging the seal.

Figure 1

Figure 2

Figure 3

Loading...

Loading...