English

11/12

PSE 120-350

7 Maintenance

a) The machine is designed and built to guarantee continuous opera-

tion; however, the life of its components depends on the mainte-

nance performed.

b) Z When requesting assistance or spare parts, identify the machine

(model and serial number) by reading the data plate located on the

unit.

c) Circuits containing 5t < xx < 50t of CO2 are checked to identify

leaks at least once a year.

Circuits containing 50t < xx < 500t di CO2 are checked to identify

leaks at least once every six months. ((EU) No. 517/2014 art. 4.3.a,

4.3.b).

d) For machines containing 5t CO2 ore more, the operator must keep a

record stating the quantity and type of refrigerant used, an quantities

added and that recovered during maintenance operations, repairs

and nal disposal ((EU) No. 517/2014 art. 6). .An example of this

record sheet can be downloaded from the site: www.polewr.com.

7.1 General instructions

! Before any maintenance, make sure:

• the pneumatic circuit is no longer pressurized;

• the dryer is disconnected from the main power supply

Y In case of refrigerant leakage, contact quali ed and authorized per-

sonnel.

Y The Schrader valve must only be used in case of machine malfunc-

tion: otherwise any damage caused by incorrect refrigerant charging will

not be covered by the warranty.

7.2 Refrigerant.

Charging: any damage caused by incorrect refrigerant replacement car-

ried out by unauthorized personnel will not be covered by the warranty.

Z

Y

The equipment contains uorinated greenhouse gases.

At normal temperature and pressure, the R513A refrigerant is a colour-

less gas classi ed in SAFETY GROUP A1 - EN378 (group 2 uid accord-

ing to Directive PED 2014/68/EU)

GWP (Global Warming Potential) = 573.

! In case of refrigerant leakage, ventilate the room.

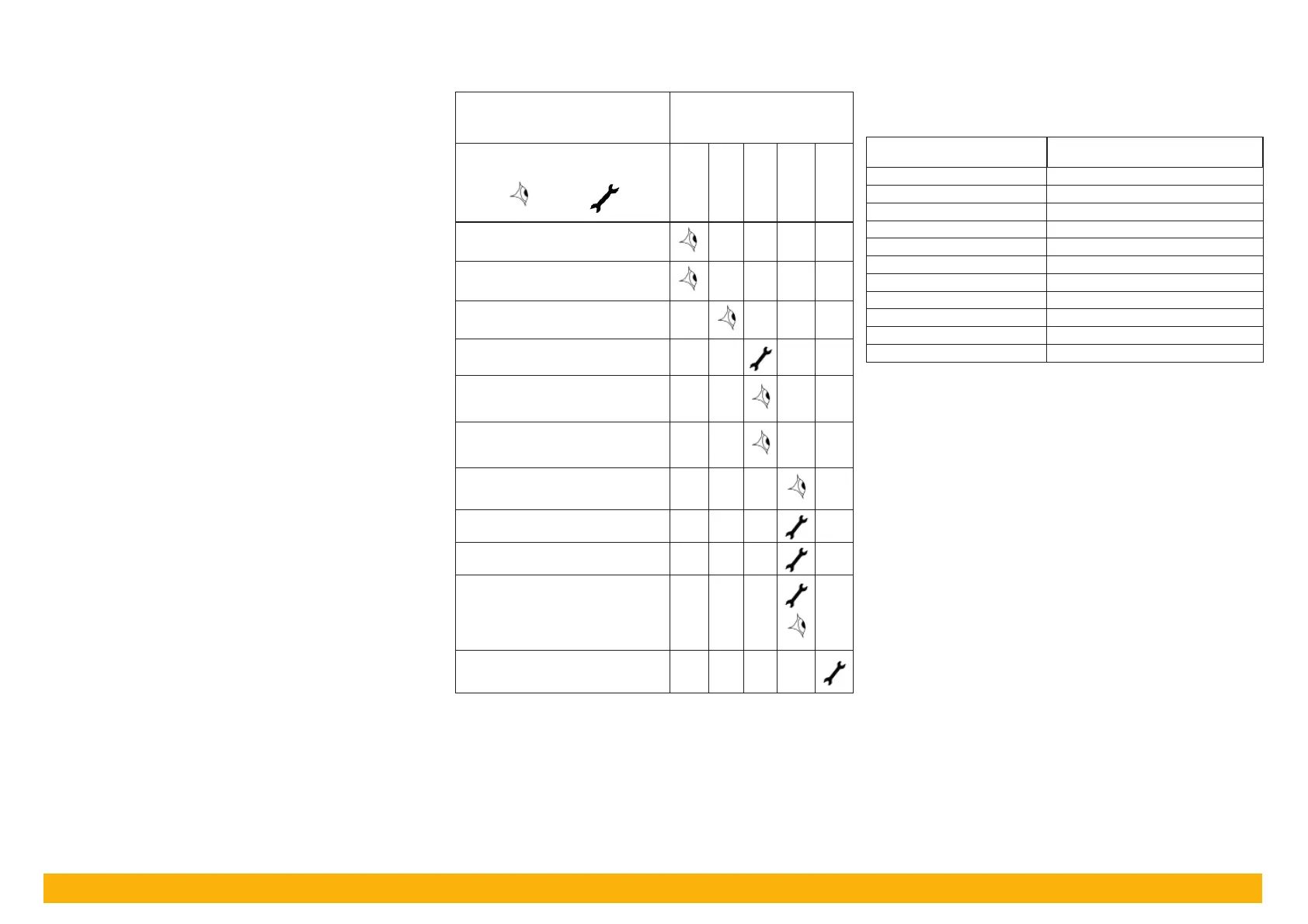

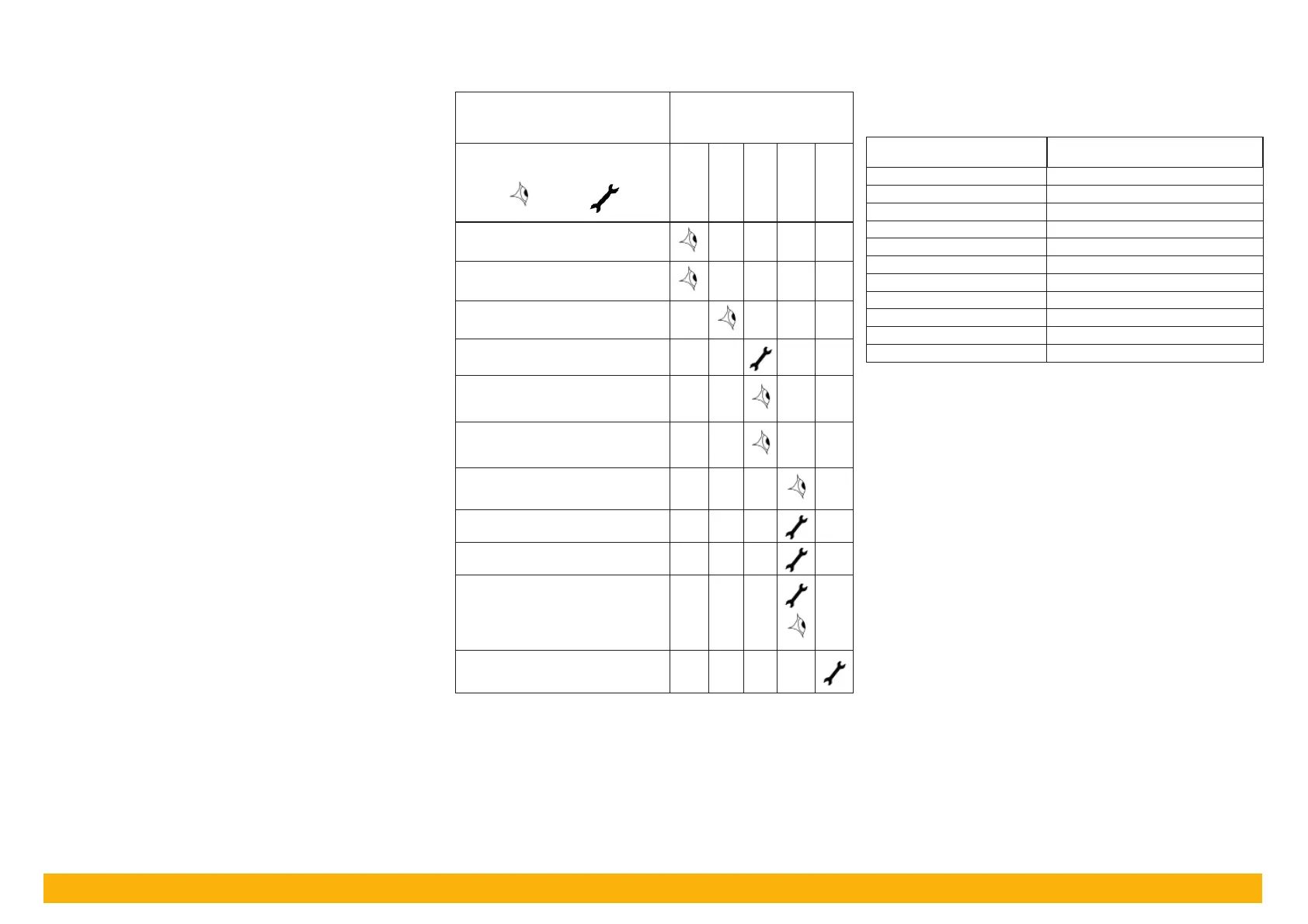

7.3 Preventive Maintenance Programme

To guarantee lasting maximum dryer ef ciency and reliability

Maintenance

Activity Description

Maintenance Interval

(standard operating condi-

tions)

Activity

Check

Service

Daily

Weekly

4 Months

12 Months

36 Months

Check POWER ON indicator is lit.

Check control panel indicators.

Check condensate drain.

Clean condenser ns.

Verify that the crakcase heater is cor-

rectly positioned

Check electrical absorption.

Check refrigerant leaks.

Depressurize the dryer. Complete

drain maintenance.

Depressurize the dryer. Replace pre-

and post- lter elements.

Check temperature sensors.

Replace if necessary.

Dryer maintenance kit.

The following are available (see par. 9.4):

a) 3 years preventive maintenance kits;

b) service kit

• compressor kits;

• fan kits;

• hot gas valve kits;

• water condenser kits;

c) individual spare parts.

7.4 Dismantling

The refrigerant and the lubricating oil contained in the circuit must be

recovered in conformity with current local environmental regulations.

The refrigerant uid is recovered before nal scrapping of the equipment

((EU) No. 517/2014 art.8).

%

Recycling Disposal Z

structural work steel/epoxy-polyester resins

exchanger aluminium

pipes/headers copper/aluminium/carbon steel

drain polyamide

exchanger insulation EPS (sintered polystyrene)

pipe insulation synthetic rubber

compressor steel/copper/aluminium/oil

condenser copper/aluminium

refrigerant R513A

valves brass

electrical cables copper/PVC

Loading...

Loading...