EN | Operating manual Technical product description

WVM 45 -1450 17

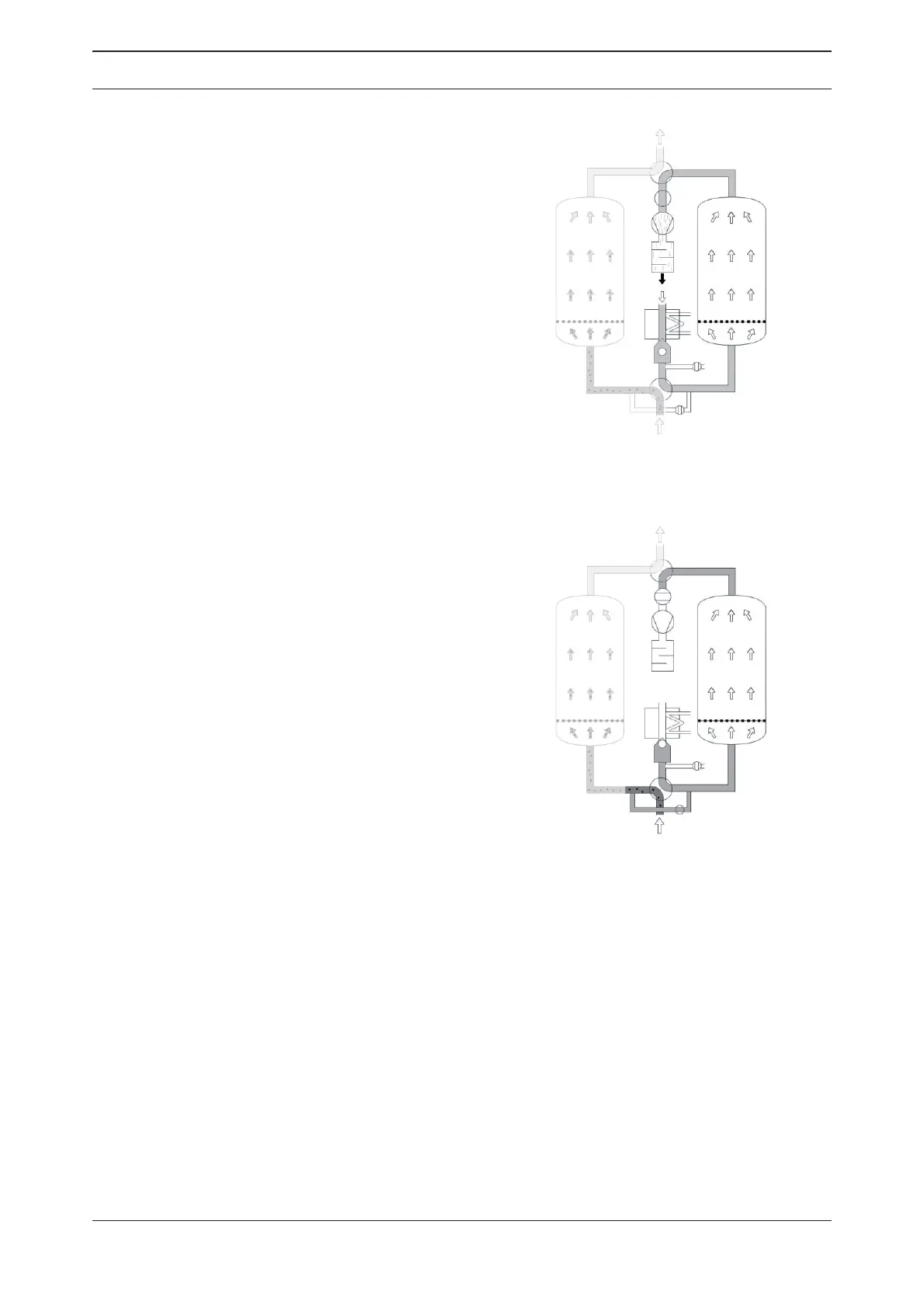

Cooling phase (duration: approx. one hour)

The hot, dried desiccant must now be cooled

and is then ready for absorption. The heater is

switched off so that the vacuum pump feeds

cold ambient air through the vessel.

If the “loop regeneration” option has been

installed, the regeneration air ows in a closed

circuit. Heat dissipation occurs via a water

cooled heat exchanger.

Advantage: No desiccant preloading with

ambient moisture.

Cooling phase

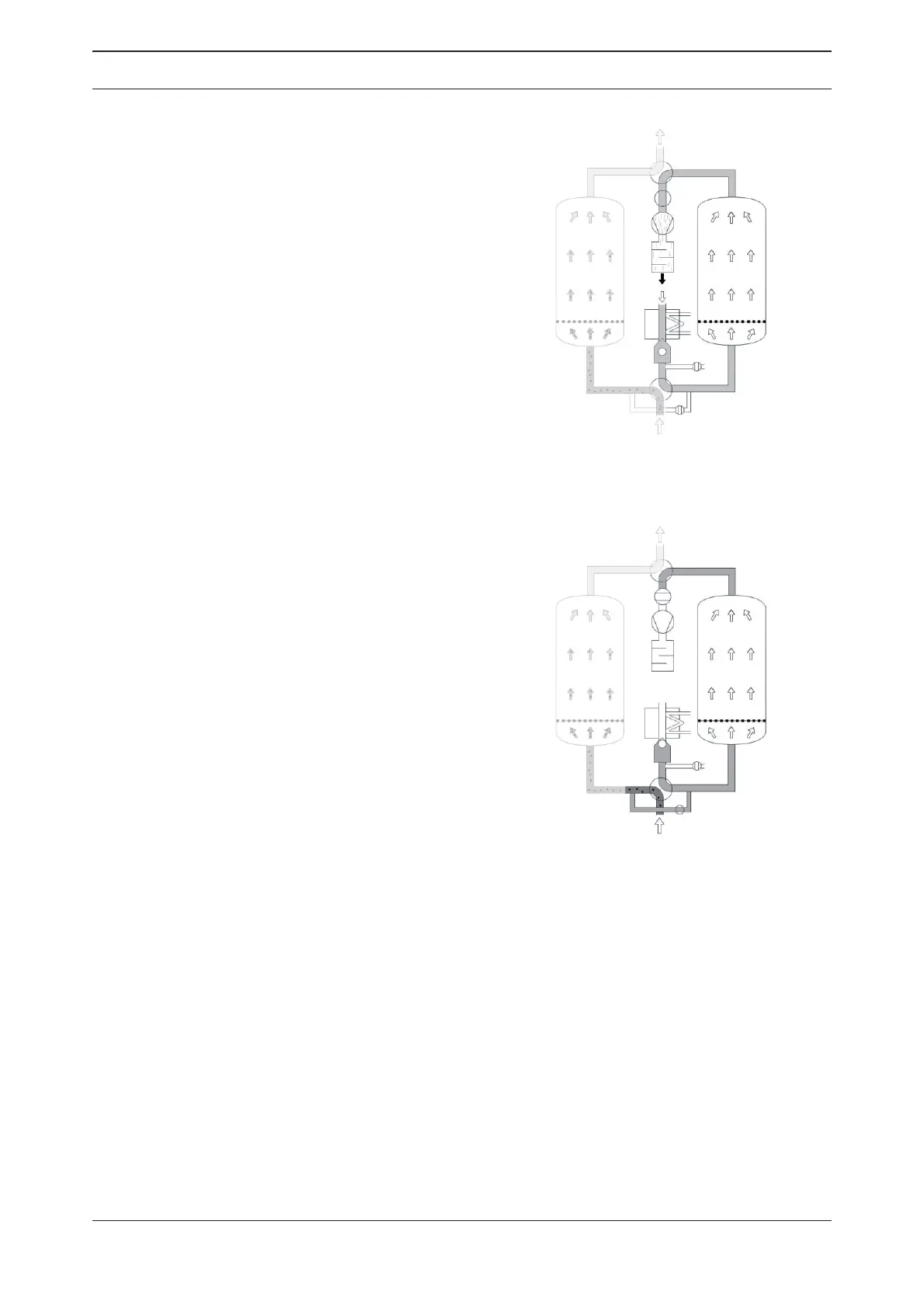

Pressure build-up phase (duration: several minutes)

After completion of the cooling phase, the

pressure in the vessel is raised to operating

pressure via the pressure build-up line.The

vessel can now be switched from regeneration

to absorption operation.

Pressure build-up

Stand-by-phase (for dewpoint measurement

option)

The regenerated vessel remains in the stand-

by phase as long as the pressure dewpoint is

better than the set switch over value. Switch

over only occurs when the switch over value is

reached or after a maximum cycle duration of

24 hours.

Switching over

In the fi xed cycle

A switch-over between the vessels occurs after 6 hours. After switching over, the process

described above is repeated, respectively exchanging the tank that was previously in adsorp-

tion with that in regeneration and vice versa.

In the variable cycle

The pressure dewpoint-dependent controller lets you operate the dryer in the xed or varia-

ble cycle.

In the variable cycle, switchover occurs in dependence of the measured pressure dewpoint.

Loading...

Loading...