EN | Operating manual Identify and eliminate faults

48 WVM 45 -1450

Identify and eliminate faults

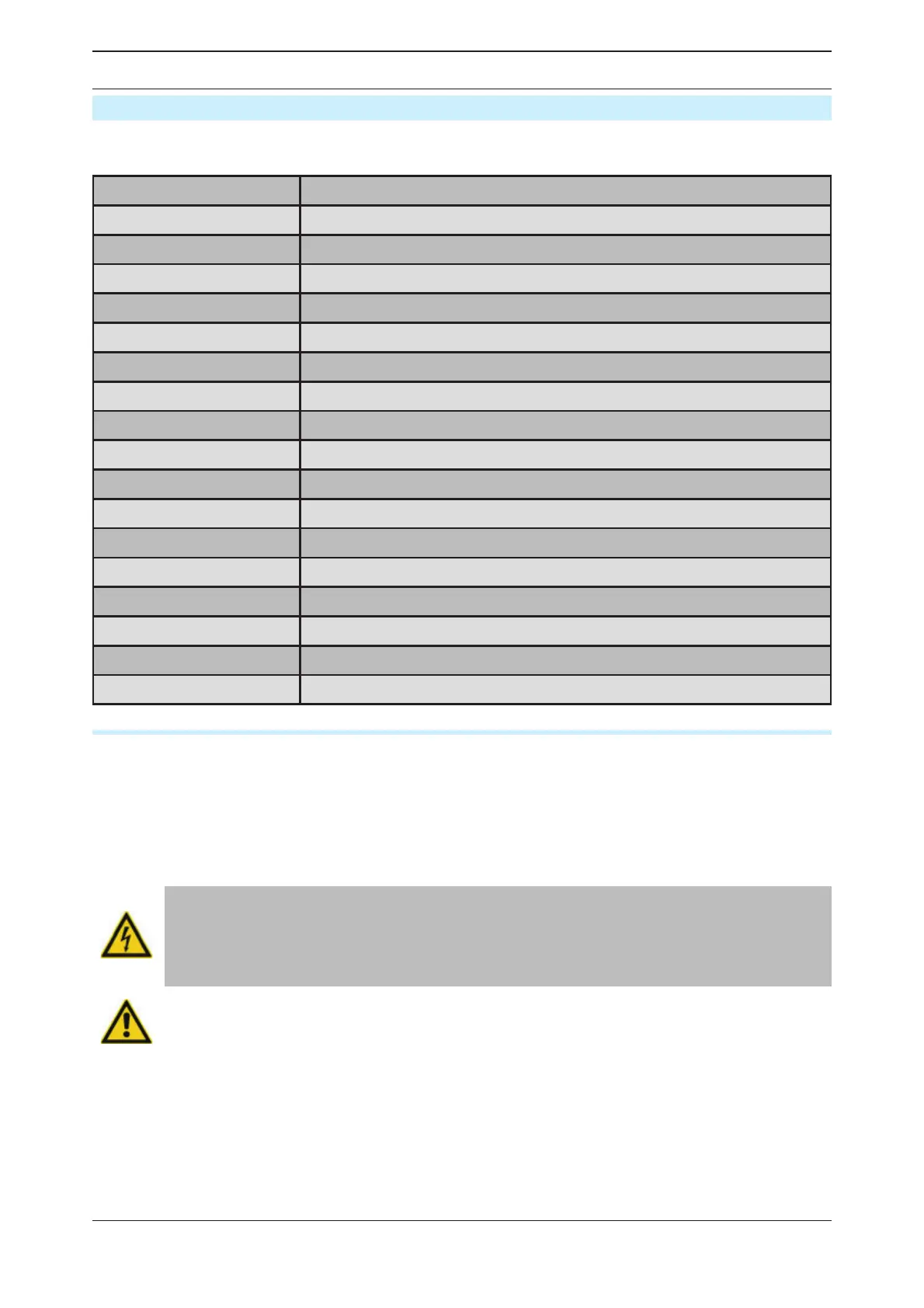

The following table provides information on what designatory abbreviations are to be used for

the various components. These designations are also found in the technical documentation.

Abbreviation Component

AA Fittings, general

AK Butter y valve

AR Check valve

AU Cardan shaft

AV 4/2-way tap cock

BB Dummy plug/ ange

BF Sieve bottom/desiccant sieve/ ow distributor

BS Silencer

BT Dessicant

GS Limit position monitor

H Air heater

MT Moisture measurement/pressure dewpoint

PT Pressure measurement

PI Pressure gauge

TT Temperature measurement

TSH Delimiter thermostat

V Vacuum pump

Notes on error messages and errors

The error message from the dryer are displayed on the operating panel. The controller manual

provides appropriate information. You are given information on the possible causes for the

error and tips how to eliminate the error.

If the dryer is connected to a fault signalling system, all error messages are transmitted

through the potential-free busbar connection to the operator’s control room.

Also heed the following notes when working at the electric system:

Electric current warning!

Work on the electrical system must only be carried out by qualifi ed technical

personnel! The electrical panel in particular must be opened and serviced by an

instructed trained electrician only.

Caution!

Arbitrary changes to the factory settings of the control programme may result

in damage to the dryer.

Loading...

Loading...