EN | Operating manual Installation

28 WVM 45 -1450

Installation of pipelines

To ensure proper operation of the dryer, its connection to the compressed air system must be

free from stress.

Prior to installation, check all incoming and outgoing compressed air lines and valves for

damage or contamination.

Inspect screw connections and retighten, if necessary (screw connections might become

loose during transport).

Ensure that the pipelines are not under any stress when installed!

Stress on pipes might result in the rupturing of the lines during operation, re-

sulting in damage to persons and property.

Connect the dryer to the compressed air system, while heeding rated diameter and

pressure.

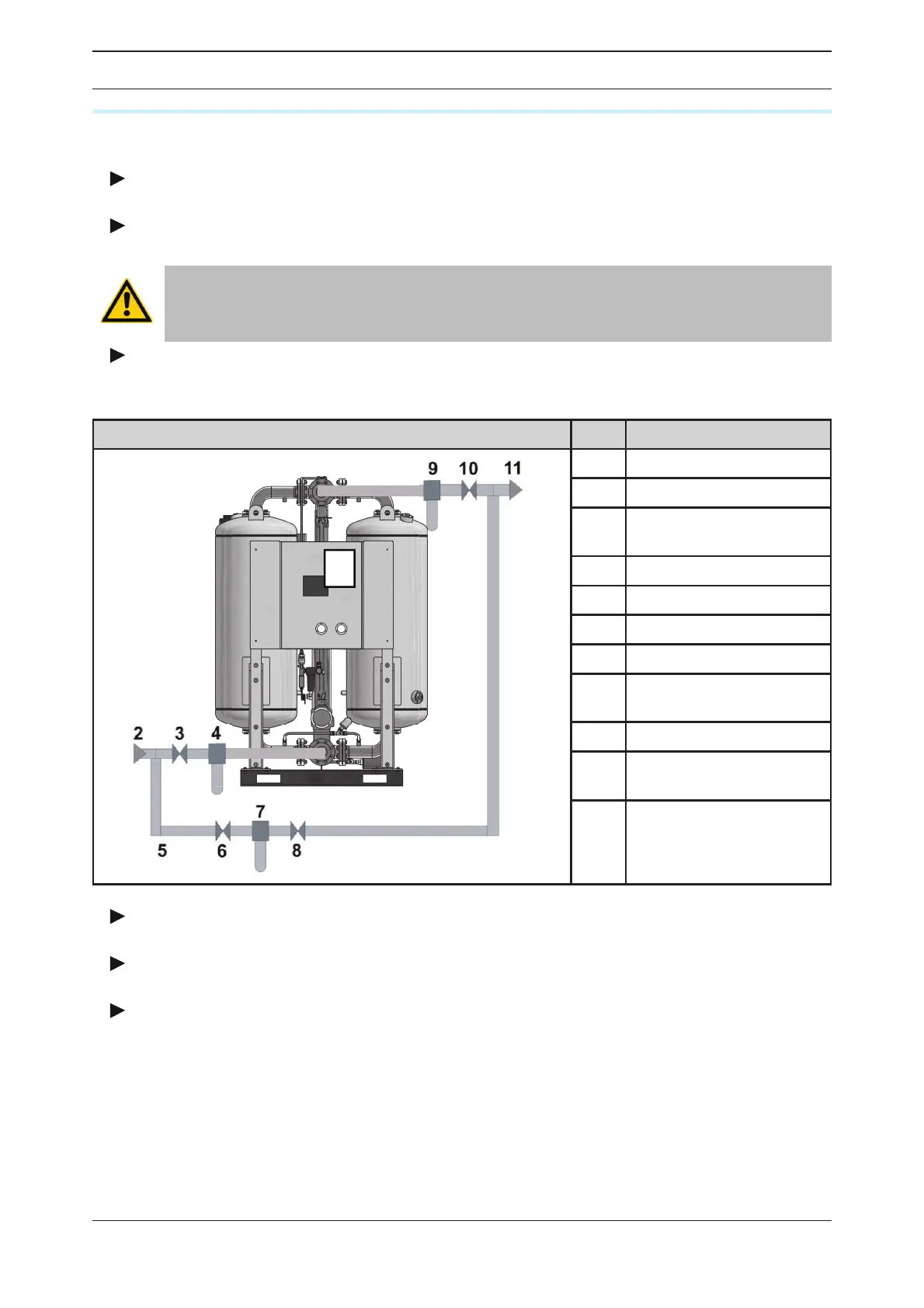

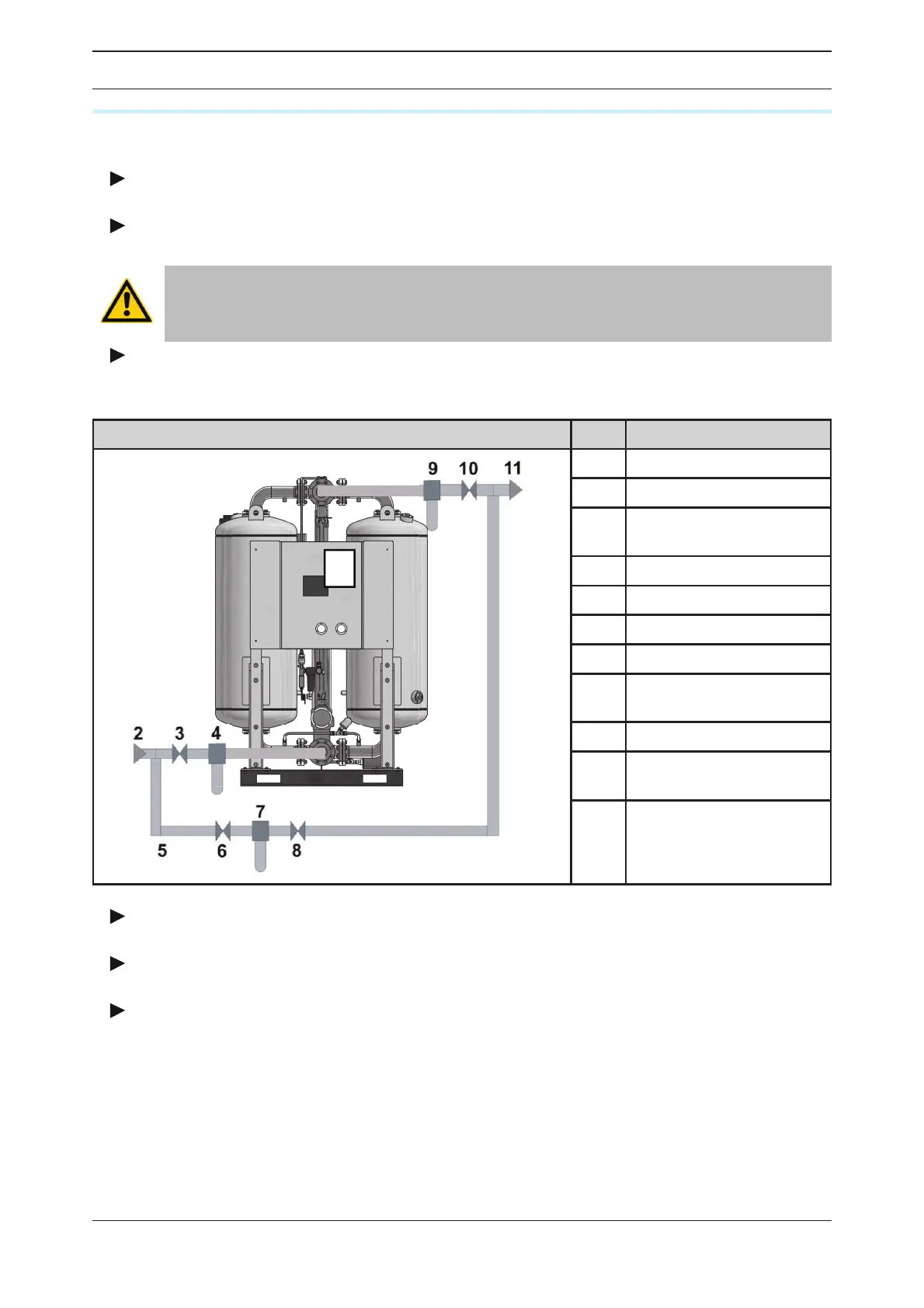

The gure below shows a proper installation.

Compressed air system Item Component

1

1 Dryer

2 Humid air inlet

3

Compressed air inlet

valve

4 Pre- lter

5 Bypass line

6 Valve in bypass line

7 Bypass lter

8

Valve at outlet of by-

pass lter

9 After lter

10

Compressed air outlet

valve

11 Dry air outlet

Example of a proper installation with bypass line

The connecting lines of the preliminary lter (4) should be at a slight slope towards the

lter.

A shut-off valve (3, 10) at both the inlet and outlet for the compressed air must be in-

stalled.

In units with bypass line (5) and additional shut-off valve:

Ensure that the line is installed in such a way that the compressed air ow must not be inter-

rupted during maintenance of the dryer.

Loading...

Loading...