- 15 -

4560 Mini Bench Top Reactors

Parr Instrument Company

Revision 6-28-02

PERIODIC PRESSURE TESTS

Each cylinder used in a Parr stirred

reactor is tested under hydrostatic pressure

to 1.3 times its maximum rating before it is

released from the factory. Micrometer

caliper measurements are taken during this

test to check the deflection of the walls of

the cylinder under pressure. Excessive

deflection or failure of the metal to resume

its original dimensions after pressure is

released indicates that a cylinder is

potentially unsafe and it will be rejected.

Similar tests should be made at regular

intervals during the life of each cylinder, and

particularly whenever the user suspects that

the equipment has been over-stressed or

damaged.

Some laboratories maintain hydraulic

test facilities and make it a rule that all

pressure vessels must be tested at regular

intervals. Records are kept of deflections at

specific test pressures so that any increase

in deflection becomes a warning that the

metal has lost strength. Any cylinder which

fails to return to its original dimensions after

application of the prescribed hydrostatic test

should be discarded as unsafe for further

use.

Users who do not have pressure test

facilities can return any Parr pressure vessel

to the factory for hydrostatic testing and

overhaul. This should be done whenever

the metal shows excessive damage from

corrosion or whenever an over-pressure or

other unusual occurrence raises any safety

questions. Apparatus returned for testing

and overhaul should be shipped prepaid to

the Parr Instrument Company,

211-53

rd

Street, Moline, Illinois 61265. An

order or letter of instructions should be

mailed to the same address, as no repair

work will be started without specific

instructions. A return authorization number

is required as well as a certificate of

cleanliness signed by a responsible user.

ACCESSORIES

Liners

Glass or PTFE liners can be

furnished to fit most Parr reactors. These

liners slide into the cylinder. Although they

will not keep corrosive vapors from reaching

the surfaces of the cylinder and head, they

make it much easier to add and remove

liquid reactants, and they give some

protection to the cylinder when working with

corrosive solutions. It must be noted,

however, that adding a PTFE liner will slow

the heat transfer rate into the vessel, and it

may be necessary to adjust the temperature

control method to prevent overheating.

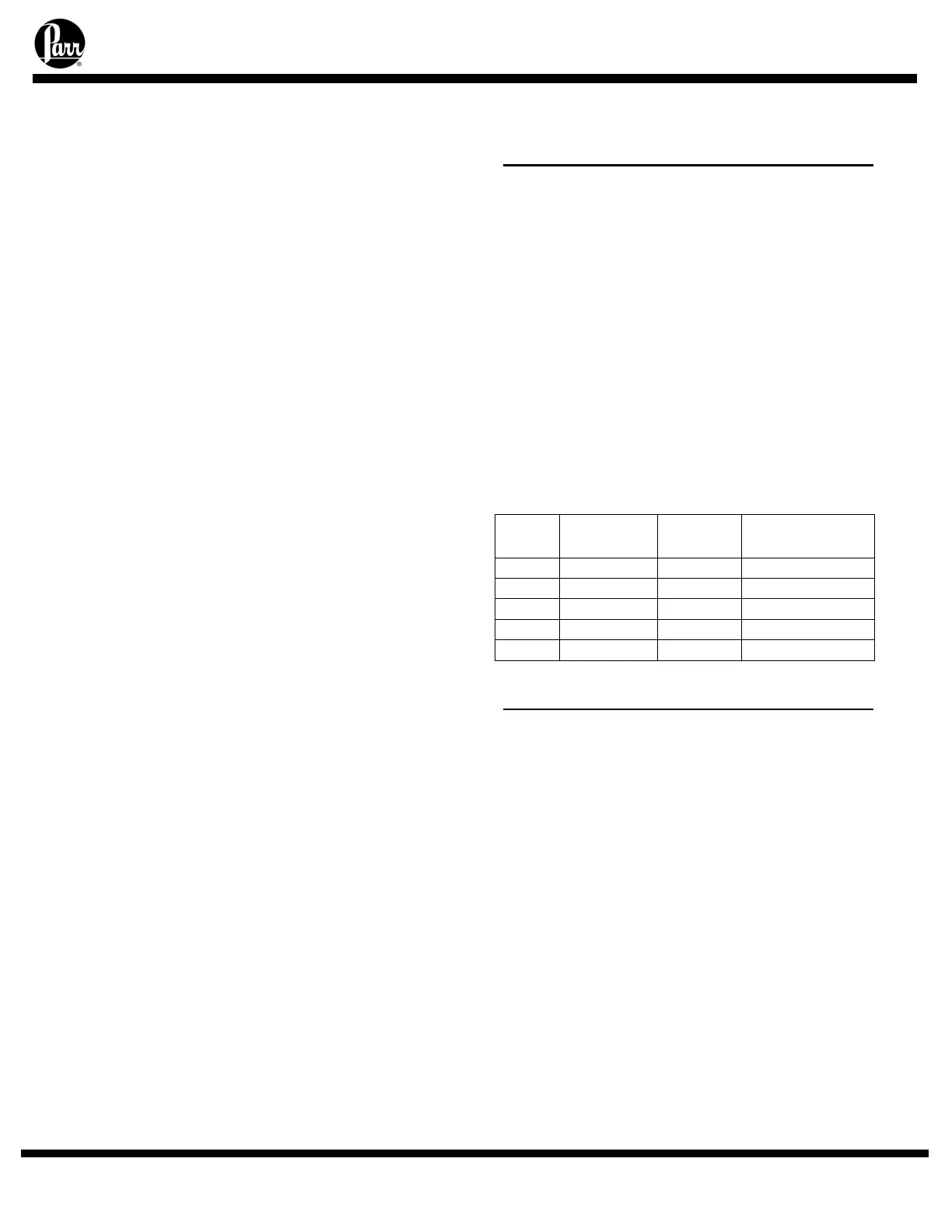

Liner Part Numbers

Fits

ID

Cylinder

Size

Glass

Liner

PTFE

Liner

2.06" 100 mL 762HC7 762HC7HA

2.5" 160 mL 762HC8 762HC8HA

2.5” 300 mL 762HC 762HC4HA

2.5" 450 mL 762HC2 762HC5HA

2.5" 600 mL 762HC3 762HC6HA

Spare Parts Kit

Spare parts kits are available for

these reactors. The kits will provide a

reserve supply of parts and tools sufficient to

handle most normal replacements and

emergency repairs during a year of heavy

usage.

The kits contain small perishable

items required for continuous operation

including gaskets, bushings, rupture discs

and seals. They can be ordered from any

Parr Dealer or direct from the Parr

Instrument Company. The order must

specify the reactor size and indicate type of

rupture disc, stirrer drive and whether it has

a flat-gasket or O-ring closure. It is most

advantageous to provide the complete

vessel number from the head or cylinder.

Loading...

Loading...