www.parweld.com

6

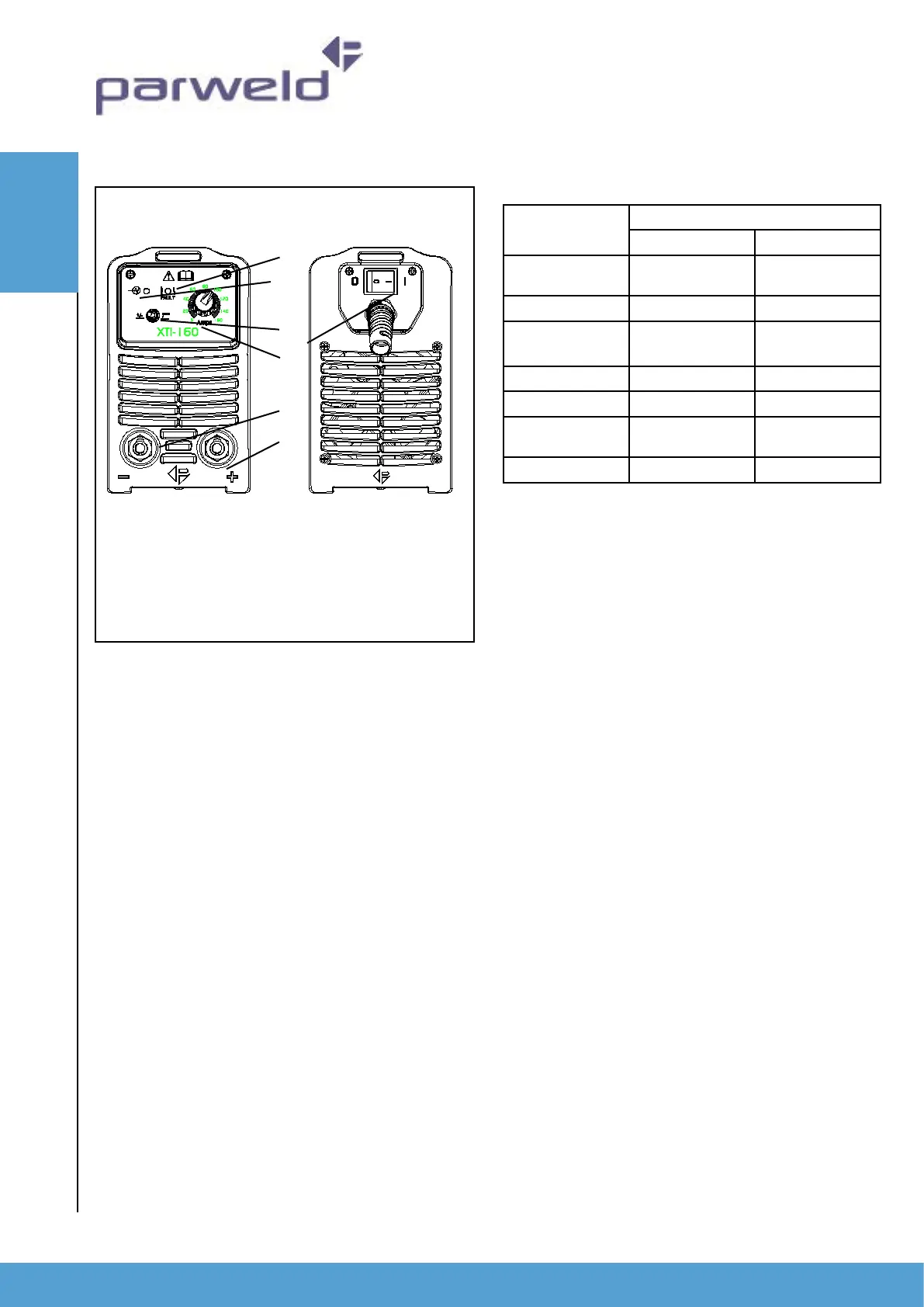

3.0 Technical Specicaons

Machine Model

XTI-160 XTI-161 DV

Input voltage 230V +/- 10%

230/110V +/-

10%

Frequency 50/60Hz 50/60Hz

Input current

32A max

16 e

25/42.5A max

16/27 e

Fuse rang 16A 16/32A

Output OCV 62 58

Output load

voltage

20.2-26.4 20.2-26.4

Output Current 5-160A DC 5-160A DC

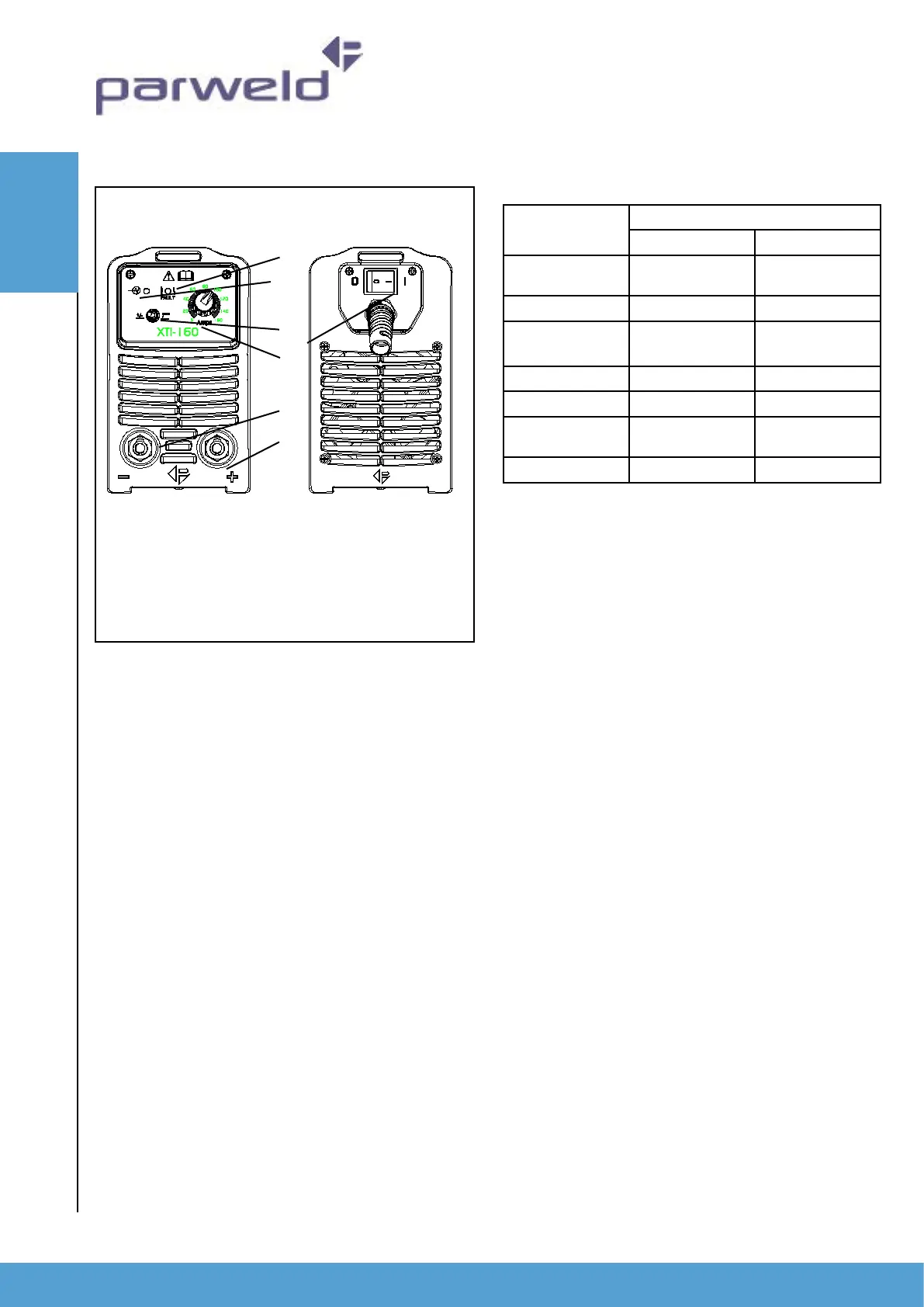

4.0 Descripon of Controls

1) ON OFF Switch for switching on or o the mains

supply to the machine. Note the output of the

machine is permanently on unless the on/o switch is

in the o posion.

2) Fault light This indicates a fault or over temperature

condion with the machine refer to the fault nding

secon for further informaon

3) Power light This indicates mains power is applied

to the machine and that the machine is currently

switched on when the light is illuminated

4) MMA/LIFT-ARC selector switch Used to select

between MMA welding mode and Li-arc TIG welding.

5) Output power control for adjustment of the power

out put of the machine in LIFT-TIG or MMA mode

6) Output power connecon - (Negave) this is the

50mm Dinse connecon socket for the connecon of

the negave welding lead.

7) Output power connecon + (Posive) this is the

50mm Dinse connecon socket for the posive

welding lead.

5.0 Installaon

Read enre installaon secon before starng

installaon.

SAFETY PRECAUTIONS

• ELECTRIC SHOCK can kill.

• Only qualied personnel should perform this

installaon.

• Only personnel that have read and understood the

Operang Manual should install and operate this

equipment.

• Machine must be grounded per any naonal, local

or other applicable electrical regulaons.

• The power switch is to be in the OFF posion when

installing work cable and electrode cable and when

2.0 Product Descripon

This welding machine is manufactured

using advanced inverter technology. The input

voltage is reced to DC and then inverted to high

frequency AC voltage. before being converted back

to DC for the output .This allows the use of a much

smaller transformer and so allowing weight saving and

improved power eciency.

1

2

3

4

5

6

7

COntrOlS

Loading...

Loading...