Basic

Component Testing

Component Tests (Input) Con

t

'd..

.

Thermistor (Variable Resistance,

2-

wire) Tests Con 't..

.

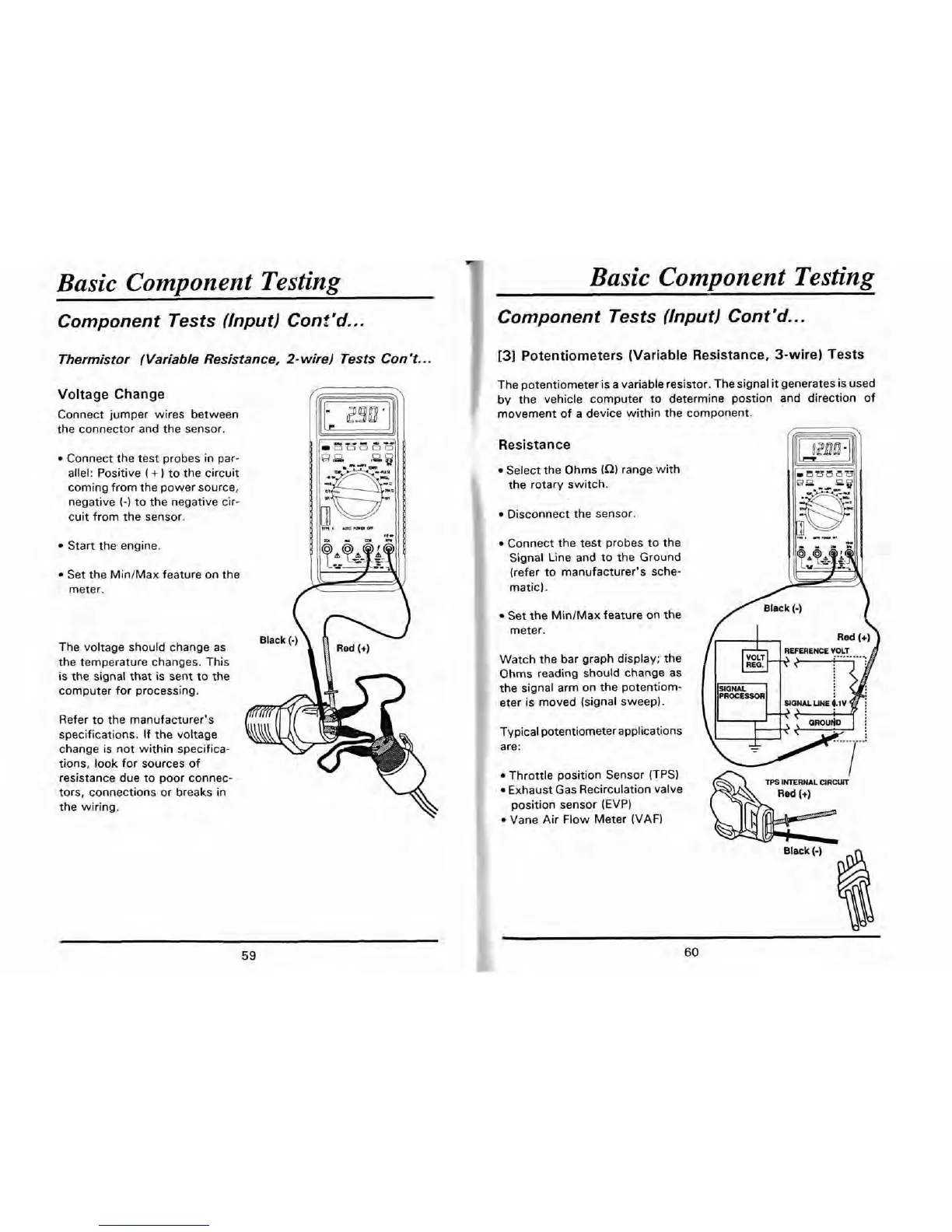

Voltage Change

Connect jumper wires between

the connector and the sensor.

Connect the test probes in par-

allel: Positive

(

+

)

to the circuit

coming from the power source,

negative

(-1

to the negative cir-

cuit from the sensor.

Start the engine.

Set the MinIMax feature on the

meter.

Black

(-)

The voltage should change as

the temperature changes. This

is the signal that is sent to the

computer for processing.

Refer to the manufacturer's

specifications. If the voltage

change is not within specifica-

tions, look for sources of

resistance due to poor connec-

tors, connections or breaks in

the wiring.

Basic Component Testing

Component Tests {Input) Con t

'd..

.

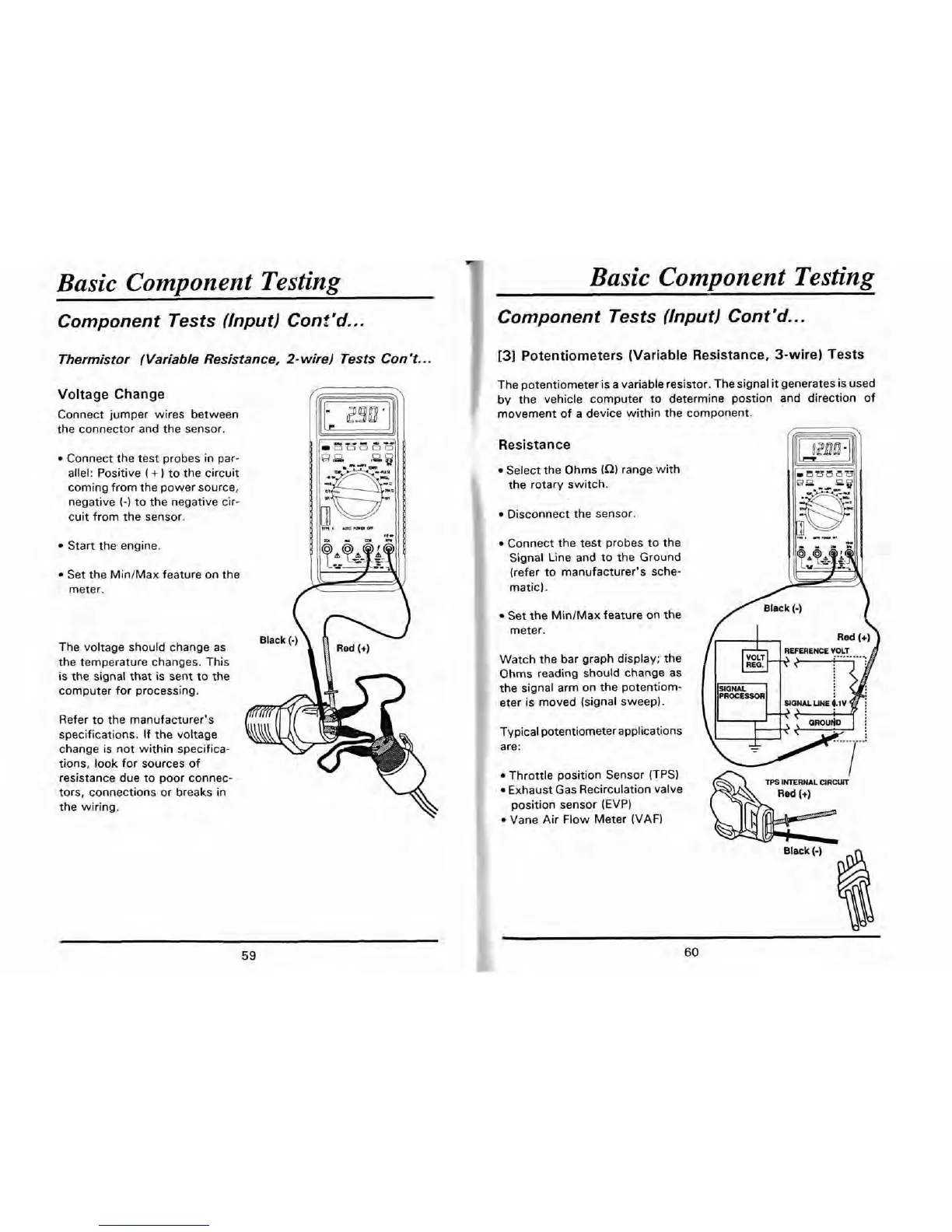

[3]

Potentiometers (Variable Resistance, 3-wire) Tests

The potentiometer is a variable resistor. The signal

it

generates is used

by

the vehicle computer to determine postion and direction of

movement of a device within the component.

Resistance

Select the

Ohms

(a)

range with

the rotary switch.

Disconnect the sensor

Connect the test probes to the

Signal Line and to the Ground

(refer to manufacturer's sche-

matic).

Set the MintMax feature on the

/

Black

(-)

I

meter.

Watch the bar graph display; the

Ohms reading should change as

the signal arm on the potentiom-

eter is moved (signal sweep).

Typical potentiometer applications

are:

Throttle position Sensor (TPS)

/

TPS

INTERNAL

CIRCUIT

Exhaust Gas Recirculation valve

position sensor

(EVP)

Vane Air Flow Meter WAF)

~-

Black

(-)

Loading...

Loading...