42

STARTING UP

- Before running, this Manual must have been carefully read and the instructions followed; wrong

settings and operations are thus prevented that could cause operating faults

- Before starting the system, the pumps must be primed (filling and air bleeding)

- After performing the operations described in the INSTALLATION chapter, the inverter can be started.

- When STEADYPRES is switched on, it enters the STARTING phase, which lasts 10 seconds, after

which STEADYPRES returns to the same operating conditions in which it was when it was last

switched off:

o in WORK mode if at the time of the last shutdown was IN SERVICE

o in OUT OF SERVICE mode if at the time of the last shutdown was OUT OF SERVICE

(OFF)

- In case of accidental fall of the power line, if it STEADYPRES was in serivce, when the power returns,

it automatically returns in service

- To put STEADYPRES IN SERVICE / OUT OF SERVICE, beat the START / STOP button.

- In applications with parallel inverters (MASTER / SLAVE) is just the MASTER inverter that receives input

from the keyboard

- SLAVE inverters operate independently only if the MASTER is turned off, in which case they receive input

from its own keyboard.

- In each group can be only one MASTER, one SLAVE 1 and one SLAVE 2.

- In normal operation, you can view the status parameters.

For visualization of the operating parameters see QUICK INSTALLATION GUIDE

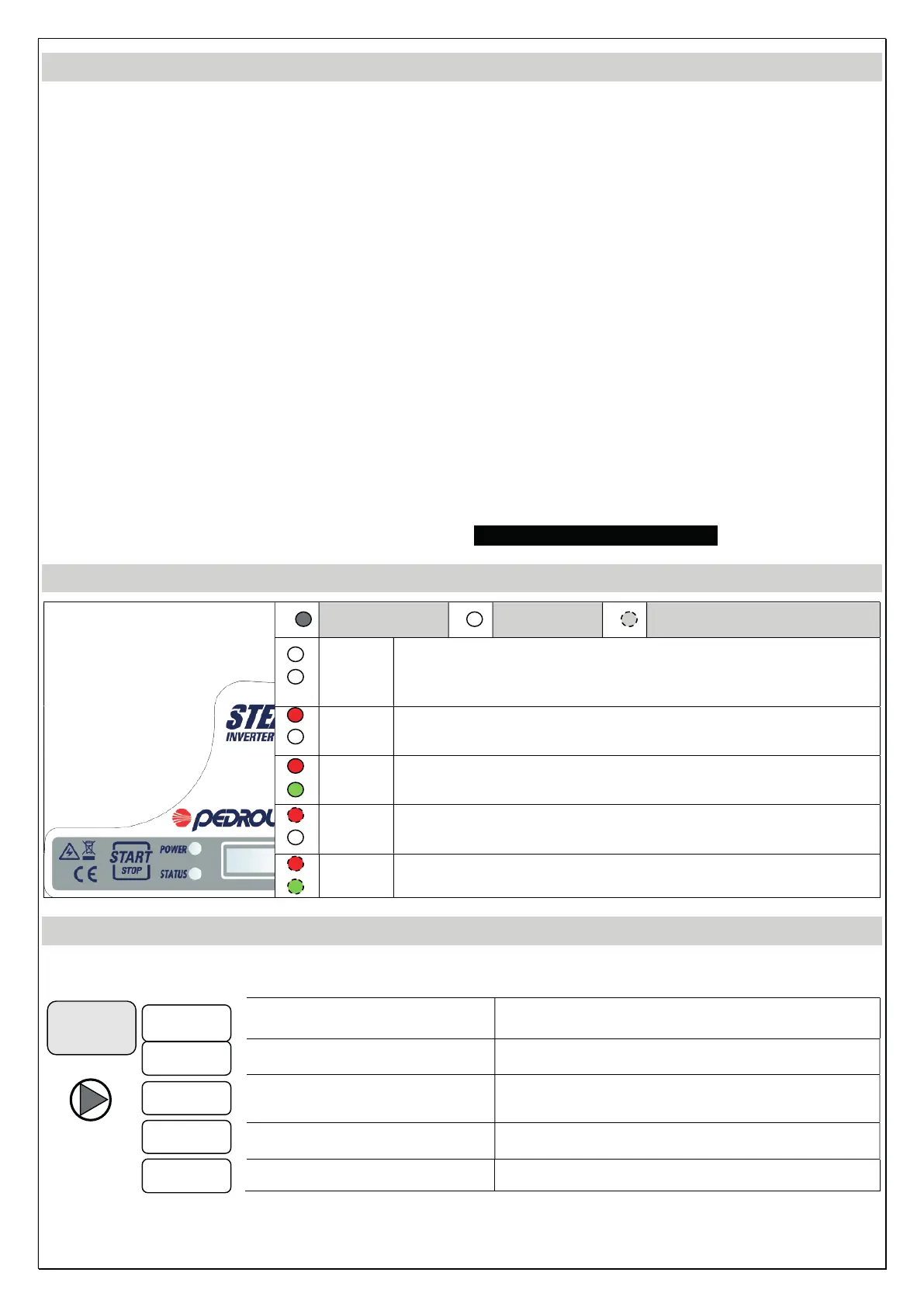

LIGHT SIGNALS

keyboard

ON OFF BLINKING

POWER

STATUS

STEADYPRES does not detect power supply. WARNING:

cannot guarantee the absence of power supply, the

electronic board may be faulty, but under tension

POWER

STATUS

STEADYPRES is live, but the pump is not running (STAND-

BY)

POWER

STATUS

STEADYPRES is live, and the pump is running

POWER

STATUS

STEADYPRES is live, but out of serivce; the re-arm is only

manual

POWER

STATUS

STEADYPRES is in ALARM mode, re-arm is only manual

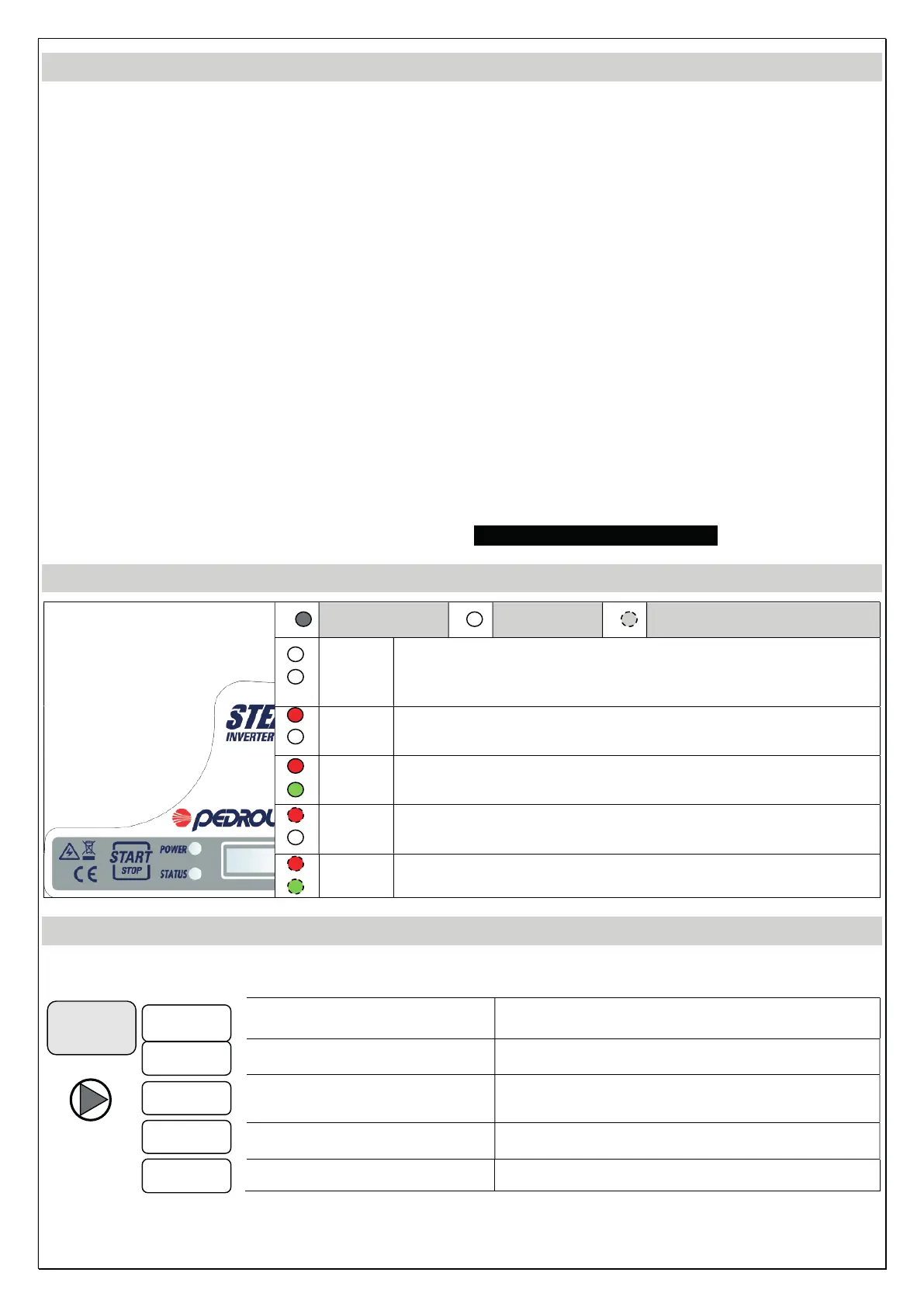

INSPECTION MENU

the menu INSP (inspection) allows you to view the history of the inverter: the operating hours,

number of starts, alarm recording.

WH

OPERATING HOURS

Operating hours with the pump running

TH

TOTAL OPERATING HOURS

Total No. Hours working

NS

NO. START-UPS

total Number of start-ups

SH

AVERAGE NO. START-UPS

Average number of start-ups per working hour.

E1 LAST FAULT

last fault that occurred in chronological order

Loading...

Loading...