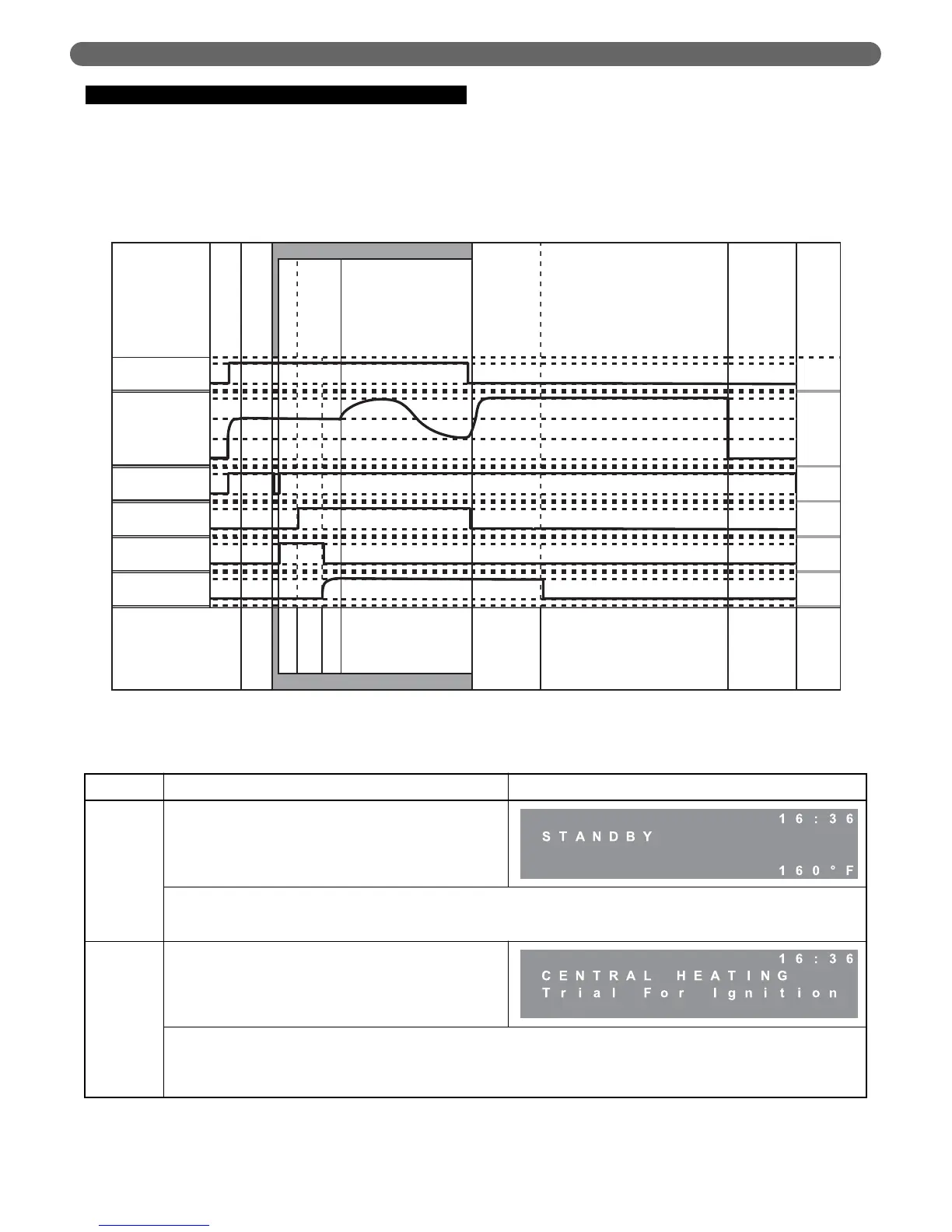

B. IGNITION SEQUENCE

Figure 8.1 shows the ignition sequence for the PUREFIRE

®

boiler control. Table 8.3 describes each step in the

sequence in detail. The P

UREFIRE

®

boiler control provides

dual sensing of the flame to maximize the reliability. The

control senses the burner flame with both the flame

sensor and the ignition electrode.

40

BOILER CONTROL: INTERNAL WIRING & OPERATION

Figure 8.1: Ignition Cycle – Graphical Representation

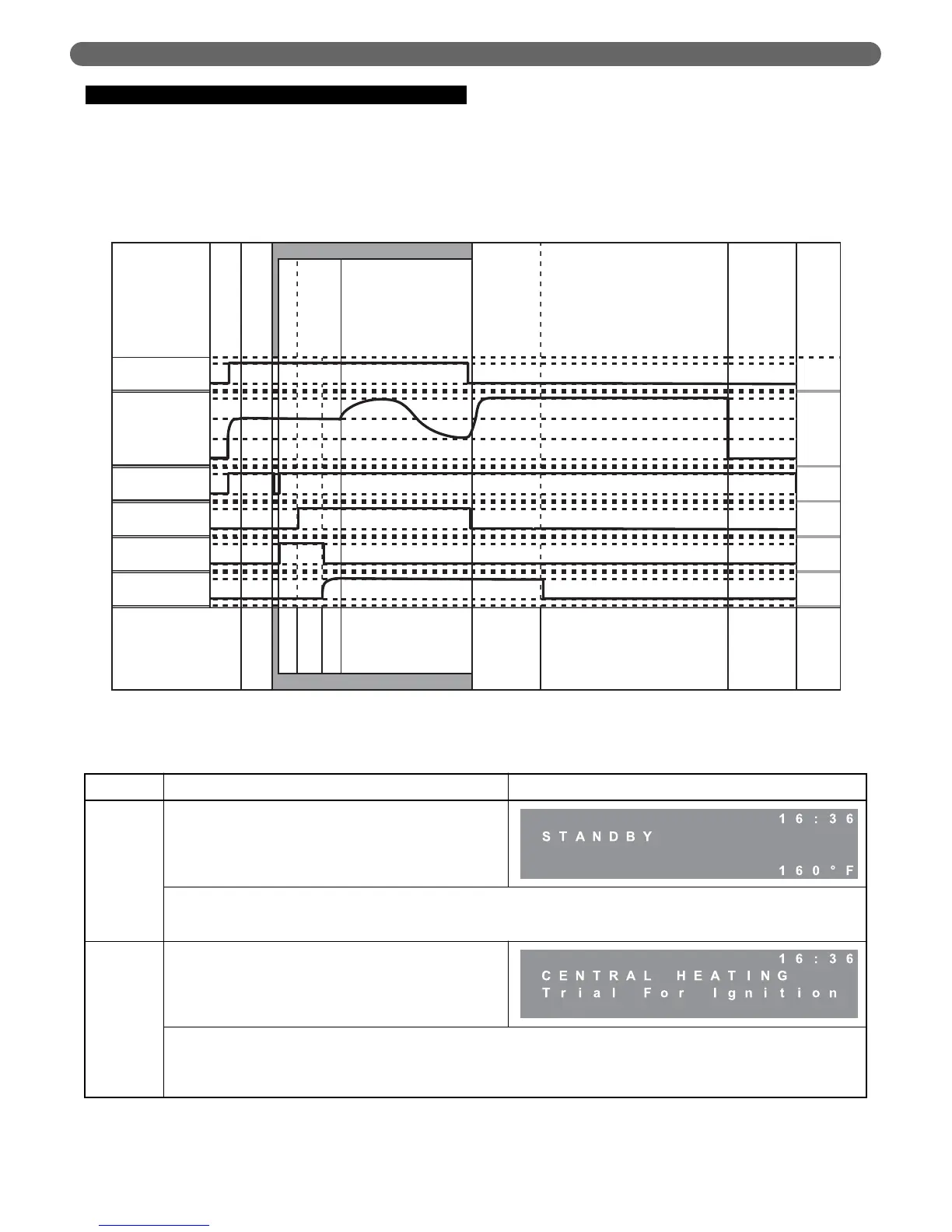

Table 8.4: Ignition Sequence

Period Demand Status User Interface Display

Standby

No demand is present

If the power is on to the PUREFIRE

®

boiler and there is no heat demand, the user interface will display “Standby” and show the

boiler supply temperature in the lower right corner. The time, in 24 hour format, is shown in the upper right. When a heat demand

(either CH or DHW) is present, the boiler begins the ignition cycle.

Pre Purge

A CH or DWH demand must be present to initiate ignition.

Once initiated the boiler will light.

When a demand is present, the PUREFIRE

®

control starts the combustion air fan. The fan speed then increases to ignition speed

and the user interface displays the Source of the call for heat along with “Trial for ignition.” This screen is displayed until the

burner is lit and stable or until a fault occurs. Once the ignition sequence begins it will continue through ignition even if the

demand has ended.

Loading...

Loading...