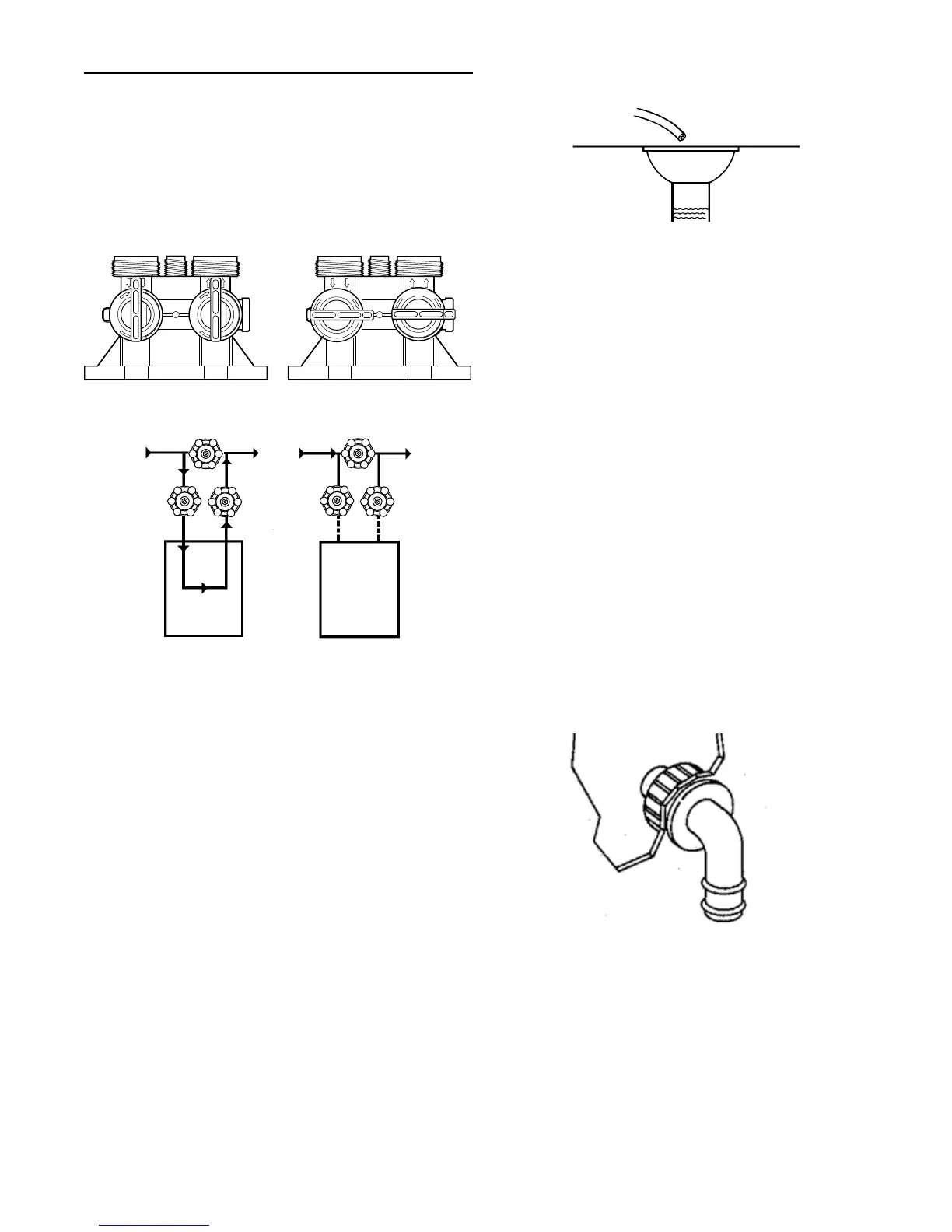

Water Line Connection

The installation of a bypass valve system is recommended to

provide for occasions when the water conditioner must be

bypassed for hard water or for servicing.

The most common bypass systems are the Autotrol

®

Series

256 bypass valve (Figure 4) and plumbed-in globe valves

(Figure 5). Though both are similar in function, the 256

Autotrol bypass offers simplicity and ease of operation.

B

Y

P

A

S

S

B

Y

P

A

S

S

Not in Bypass

B

Y

P

A

S

S

B

Y

P

A

S

S

In Bypass

Figure 4 Autotrol Series 256 Bypass Valve

Water

Conditioner

Water

Conditioner

Not in Bypass

In Bypass

Figure 5 Typical Globe Valve Bypass System

Drain Line Connection

1. Ideally located, the unit will be above and not more than

20 feet (6.1 m) from the drain. For such installations, use

an appropriate adapter fitting (not supplied), to connect

1/2 inch (1.3 cm) plastic tubing to the drain line connection

of the control valve.

2. If the unit is located more than 20 feet (6.1 m) from drain,

use 3/4 inch (1.9 cm) tubing for runs up to 40 feet (12.2 m).

Also, purchase appropriate fitting to connect the 3/4 inch

tubing to the 1/2 inch NPT drain connection.

3. If the unit is located where the drain line must be elevated,

you may elevate the line up to 6 feet (1.8 m) providing the

run does not exceed 15 feet (4.6 m) and water pressure

at conditioner is not less than 40 psi (2.76 bar). You may

elevate an additional 2 feet (61 cm) for each additional

10 psi (0.69 bar).

4. Where the drain line is elevated but empties into a drain

below the level of the control valve, form a 7-inch (18 cm)

loop at the far end of the line so that the bottom of the loop

is level with the drain line connection. This will provide an

adequate siphon trap.

5. Where the drain empties into an overhead sewer line, a

sink-type trap must be used.

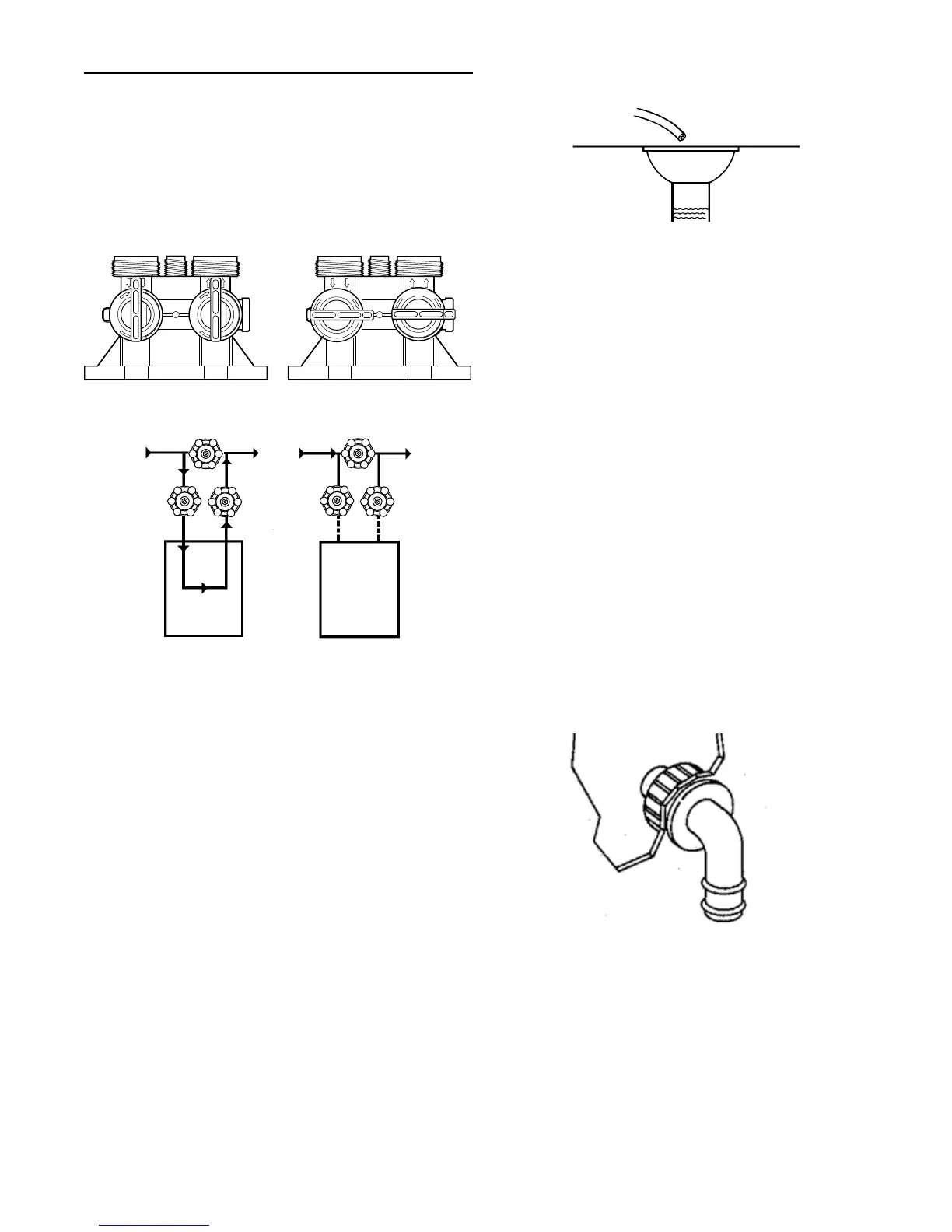

IMPORTANT: Never insert drain line into a drain, sewer line or

trap. Always allow an air gap between the drain line and the

wastewater to prevent the possibility of sewage being back-

siphoned into conditioner.

Right Way

Drain Line Tube

Drain

Correct Way

Figure 6

NOTE: Standard commercial practices have been expressed

here. Local codes may require changes to

these suggestions.

Brine Line Connection

It will be necessary to install the brine tube and line to a fitting

installed on the air check. Apply plumber tape on all

threaded connections.

Be sure all fittings and connections are tight so that premature

checking does not take place. Premature checking is when

the ball in the air check falls to the bottom before all brine

is drawn out of the brine tank. See Placing Conditioner into

Operation section.

Overflow Line Connection

In the absence of a safety overflow and in the event of

a malfunction, the BRINE TANK OVERFLOW will direct

“overflow” to the drain instead of spilling on the floor where it

could cause considerable damage. This fitting should be on the

side of the cabinet or brine tank.

To connect overflow, locate hole on side of brine tank. Insert

overflow fitting (not supplied) into tank and tighten with plastic

thumb nut and gasket as shown (Figure 7). Attach length of

1/2 inch (1.3 cm) I.D. tubing (not supplied) to fitting and run to

drain. Do not elevate overflow line higher than 3 inches

(7.6 cm) below bottom of overflow fitting. Do not tie into drain

line of control unit. Overflow line must be a direct, separate

line from overflow fitting to drain, sewer or tub. Allow an air

gap as per drain line instructions (Figure 6).

Brine Tank

Overflow Fitting

Installed

Connect 1/2-inch

(1.3 cm) Tubing or

Hose and Run to

Drain

Figure 7

Low Voltage Transformer

Use only the included transformer for powering the 400 series

timers. Connect the plug of the transformer secondary cable

to the mating socket on the control (see Figure 8).

Be certain that the transformer is plugged into a correct

voltage source that is not controlled by a wall switch.

EQUIPMENT INSTALLATION continued

AUTOTROL

®

255 Valve/400 Series Service Manual • 5

Loading...

Loading...