EQUIPMENT INSTALLATION

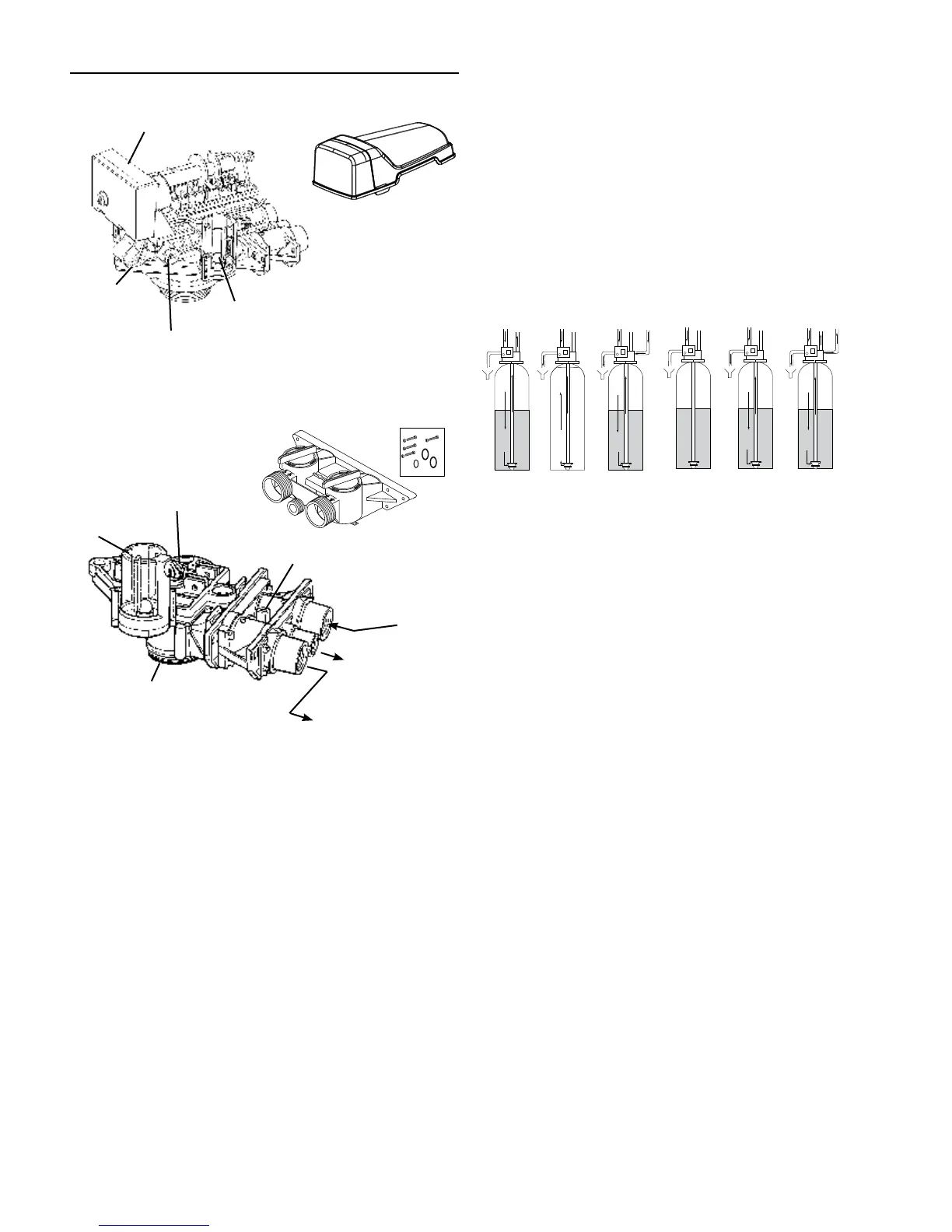

Autotrol 255 Valve Control Module Features

400 Series Control

Variable Brine

Control

Injector Access Plug

Air Check

Optional i-lid Cover

Figure 1

Tank Adapter Module Features

B

Y

P

A

S

S

B

Y

P

A

S

S

Optional Bypass

Probe Connection Slot

Air Check

Brine Line Fitting

Connection 1/4-inch NPT

Tank Thread 2-1/2 inch - 8 male

Inlet Connection

3/4-inch or 1-inch

NPT or BSPT

Drain Connection

3/8-inch or

1/2-inch NPT or

BSPT

Outlet connection

3/4-inch or 1-inch

NPT or BSPT

Figure 2

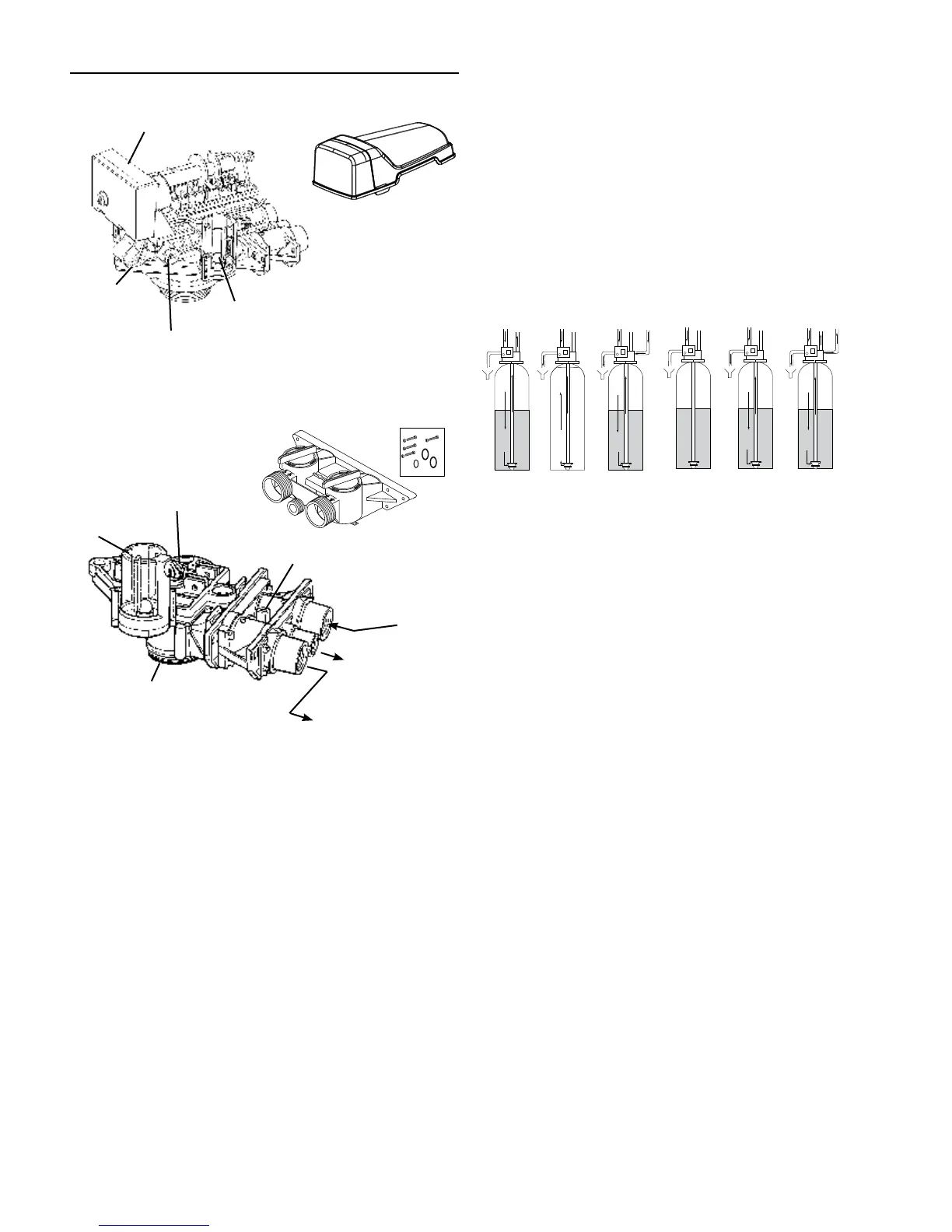

System Regeneration Cycles

1. Service (Downflow):

Untreated water is directed down through the resin bed and up

through the riser tube. The hardness ions attach themselves

to the resin and are removed from the water. The water is

conditioned as it passes through the resin bed.

2. Backwash (Upflow):

The flow of water is reversed by the control valve and directed

down the riser tube and up through the resin bed. During the

backwash cycle, the bed is expanded and debris is flushed to

the drain.

3. Brine/Slow Rinse (Downflow):

The control directs water through the brine injector and brine

is drawn from the regenerant tank. The brine is then directed

down through the resin bed and up through the riser tube to

the drain. The hardness ions are displaced by sodium ions and

are sent to the drain. The resin is regenerated during the brine

cycle. Brine draw is completed when the air check closes.

4. Fast Rinse (Downflow):

The control directs water down through the resin bed and

up through the riser tube to the drain. Any remaining brine

residual is rinsed from the resin bed.

5. Brine Refill (Downflow):

Brine refill occurs during a portion of the fast rinse cycle.

Water is directed to the regenerant tank at a controlled rate, to

create brine for the next regeneration.

6. Repressurize Cycle — (No Flapper Open):

This cycle closes all flappers for a short time to allow the

air and water to hydraulically balance in the valve before

continuing the regeneration.

SERVICE BACKWASH BRINE/SLOW RINSE

FAST RINSE

From Regenerant

Tank

To Regenerant

Tank

BRINE REFILL

REPRESSURIZE

C0 C1 and C6 C2 and C3

C4 C5 and C7 C8

Figure 3

NOTE: All plumbing must conform to local codes. Inspect

unit carefully for carrier shortage or shipping damage.

Location Selection

1. The distance between the unit and a drain should be as

short as possible.

2. If it is likely that supplementary water treating equipment

will be required, make certain adequate additional space

is available.

3. Since salt must be added periodically to the brine tank, the

location should be easily accessible.

4. Do not install any unit closer to a water heater than a total

run of 10 feet (3 m) of piping between the outlet of the

conditioner and the inlet to the heater. Water heaters can

sometimes overheat to the extent they will transmit heat

back down the cold pipe into the unit control valve. Hot

water can severely damage the conditioner. A 10 foot (3-m)

total pipe run, including bends, elbows, etc., is a reasonable

distance to help prevent this possibility. A positive way to

prevent hot water from flowing from heat source to the

conditioner, in the event of a negative pressure situation,

is to install a check valve in the soft water piping from

the conditioner. If a check valve is installed, make certain

the water heating unit is equipped with a properly rated

temperature and pressure safety relief valve. Also, be

certain that local codes are not violated.

5. Do not locate unit where it or it’s connections (including

the drain and overflow lines) will ever be subjected to room

temperatures under 34°F (1°C) or over 120°F (49°C).

6. Do not install unit near acid or acid fumes.

7. The use of resin cleaners in an unvented enclosure is

not recommended.

4 •AUTOTROL

®

255 Valve/400 Series Service Manual

Loading...

Loading...