26850A002 06/04/14

3

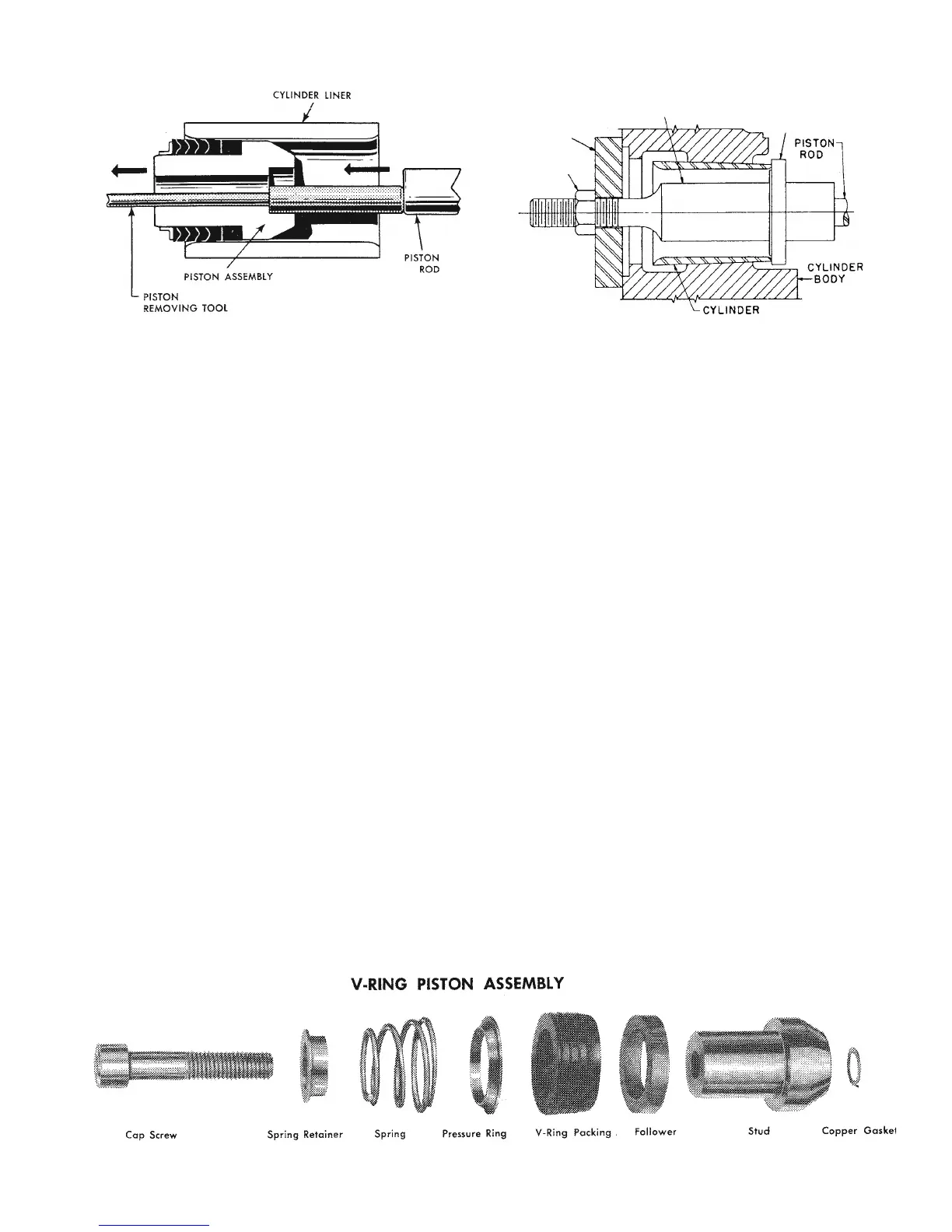

Inspect cylinders for linear grooving. If any is detected,

replace cylinders. New packing will rapidly cut or wear

out in grooved cylinders.

Assemble V-rings onto stud and lubricate the outside of

the assembly with Molykote

®

or other grease for ease in

insertion – do not use a graphite-type grease.

When installing each V-ring assembly, rotate crankshaft

until piston rod is at forward position. Place copper

gasket in position in stud using a small amount of

Permatex

®

to hold in place.

Assemble capscrew, etc., into piston assembly and push

into cylinder. Torque the cap screw to 50 ft/lbs.

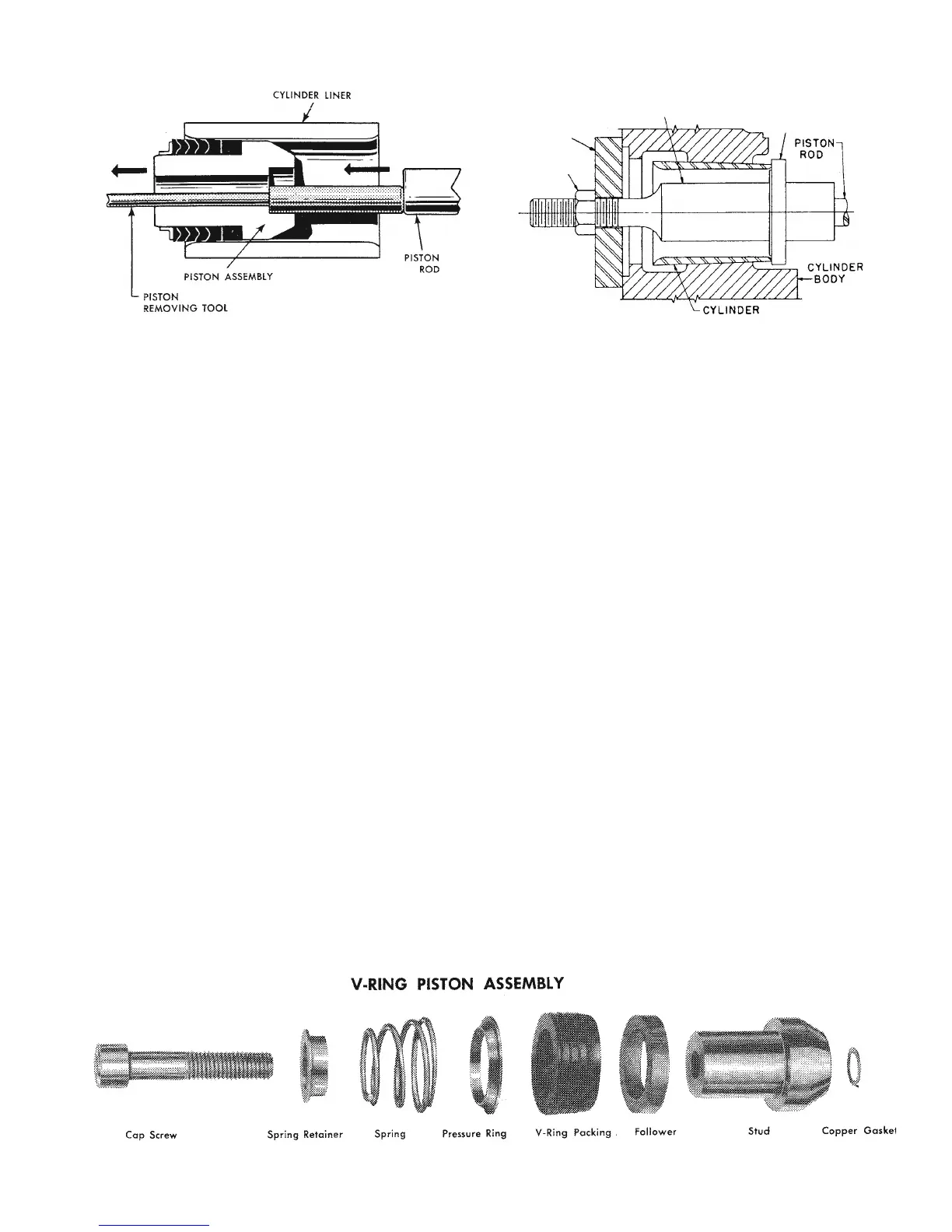

REPLACING CYLINDERS

Remove packing and rotate crankshaft until piston rod

is in rear position. Insert puller through inside of cylinder

and pilot over piston rod. Insert disc into slots on puller

and slip plate over threads on puller. Screw nut on thread

of puller and snug up. Tighten nut until cylinder breaks

loose. Loosen nut and slip disc out of slots. Remove

puller and repeat to remove other cylinders.

Reasonable care and judgment should be used when

installing the new cylinder. Clean out any accumulation

of loose rust or corrosion in cylinder body. Install a new

O-ring in groove on tapered portion of cylinder and

lubricate with oil or grease. Position cylinder carefully

by hand to avoid cutting the O-ring. Drive into position

firmly, but never use a hydraulic press as excessive force

can cause damage and make cylinders very difficult to

remove for later replacement.

REPLACING VALVE SEATS - D65-16 SERIES

First remove spring retaining bar, spring and flat valve.

When removing upper valve seat, pass head of puller

through hole in valve seat before sliding wedge is

inserted alongside puller bolt. Draw down on nut at top

of bolt. When removing lower seats, drop puller bolt

through opening for upper seat and remove in same

manner. Using sliding wedge on pumps where lower

seats are the same size as upper seats.

Place new lower seat in tapered hole in cylinder body.

Hold a soft brass or hardwood round bar against seat

and drive into place. The knocker stem is in two pieces

so that it can be shortened for installing discharge seats

after suction seats have been installed.

SCREW

NUT

PLATE

PULLER

DISC

Loading...

Loading...