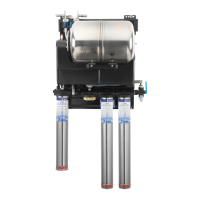

What to do if return flow to pool diminished, low filter pressure in Pentair SAND DOLLAR Water Filtration Systems?

- DDerrick ThomasJul 27, 2025

If you notice a diminished return flow to the pool and low filter pressure in your Pentair Water Filtration System, start by cleaning the basket in the strainer to remove any obstruction in the pump hair and lint pot. Next, disassemble and clean the pump to eliminate any obstructions there. Finally, clean the skimmer basket, remove any obstructions in the lines, and open the valves in the suction line to the pump.