– 48 –

1-3-3-1-2. Wrapping

1) Prior to steam sterilization, wrap the components and accessories individually with

two layers of one-ply Kimguard KC200 sterilization wrap (Kimberly-Clark) using

sequential wrapping technique.

1-3-3-1-3. Parameters

Steam sterilization can be performed under the following conditions:

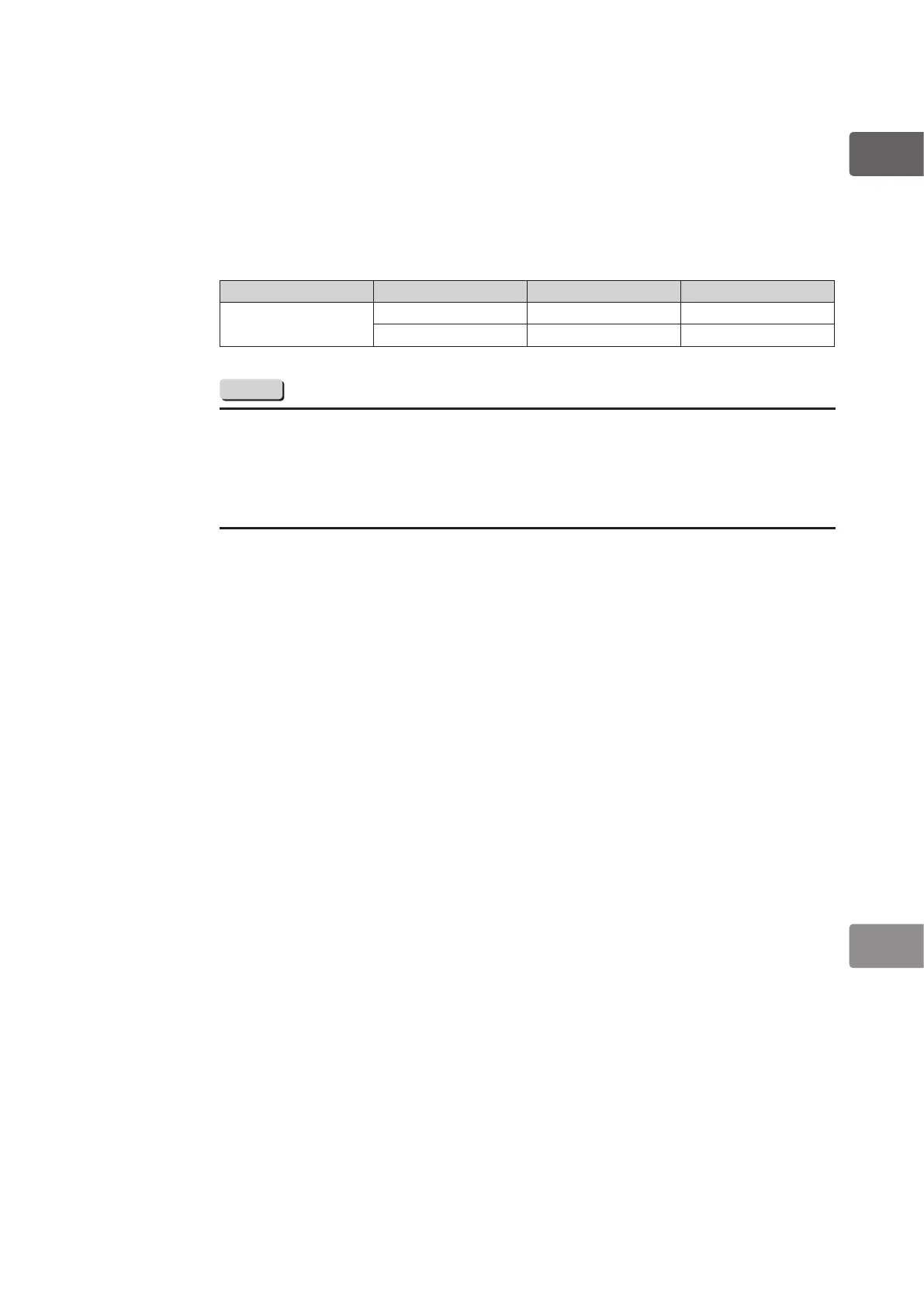

Sterilizer Type Temperature Exposure Drying Time

Pre-vacuum

132°C 4 minutes 30 minutes

135°C 3 minutes 16 minutes

• Validation testing of these parameters was performed using two layers of

one ply Kimberly Clark Wrap KC-200 Sterilization Wrap (Kimberly-Clark).

Sequential wrapping technique was employed.

• Biological and/or chemical indicators used must be appropriate for the

stated sterilization cycle parameters and cleared by FDA.

1-3-3-2. Sterilization using STERRAD

®

NX™ system

The suction control valve (OF-B179) and the inlet seal (OF-B190) can be sterilized using

the STERRAD

®

NX™ sterilization.

1-3-3-2-1. Items required

• protective garments such as gloves, gowns, face masks, etc., to minimize the

risk of cross contamination.

• APTIMAX Instrument Tray (270 mm in width, 576 mm in length, 100 mm in height)

• APTIMAX Instrument Tray Mat (254 mm in width, 546 mm in length)

• instrument wrap recommended by STERRAD

®

for use of STERRAD

®

NX™

system

• tape recommended by STERRAD

®

for use of STERRAD

®

NX™ system

Accessory

Sterilization

1

Loading...

Loading...