21

Door Interrupt System with FYQLA1-140R-3 Logic Amplier

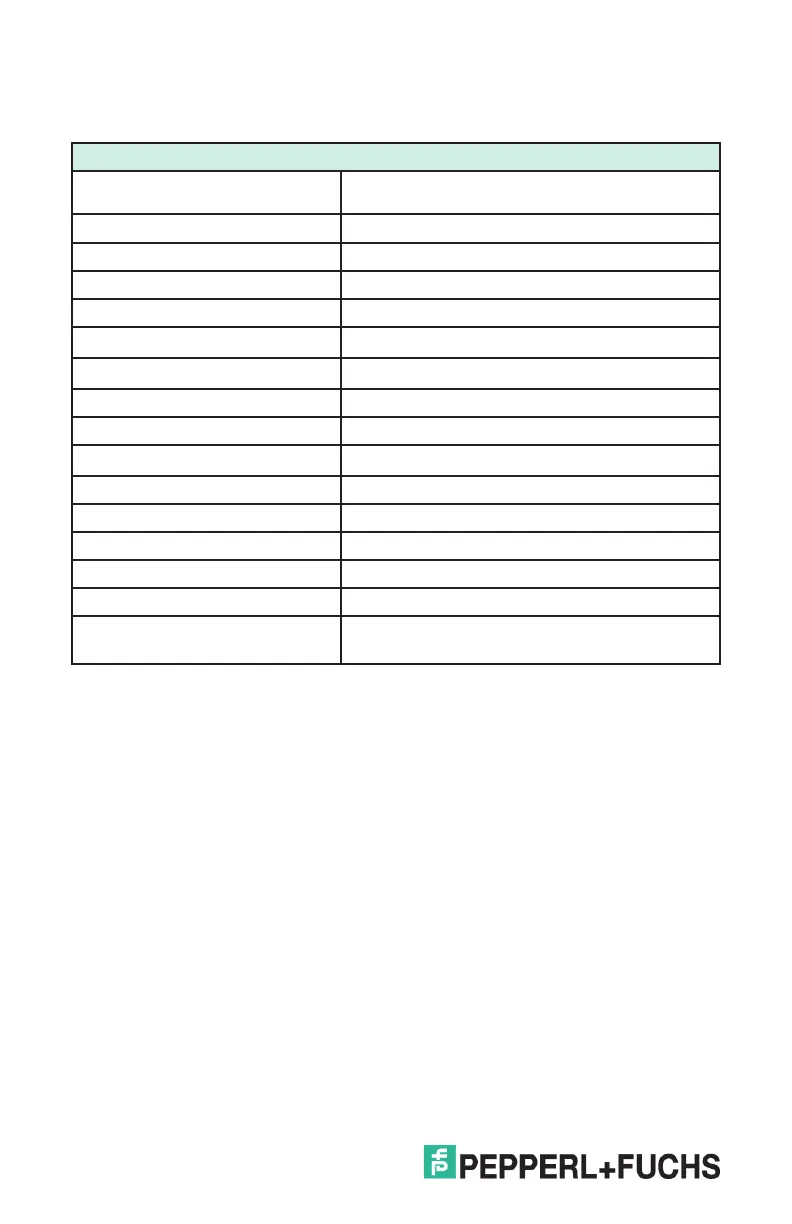

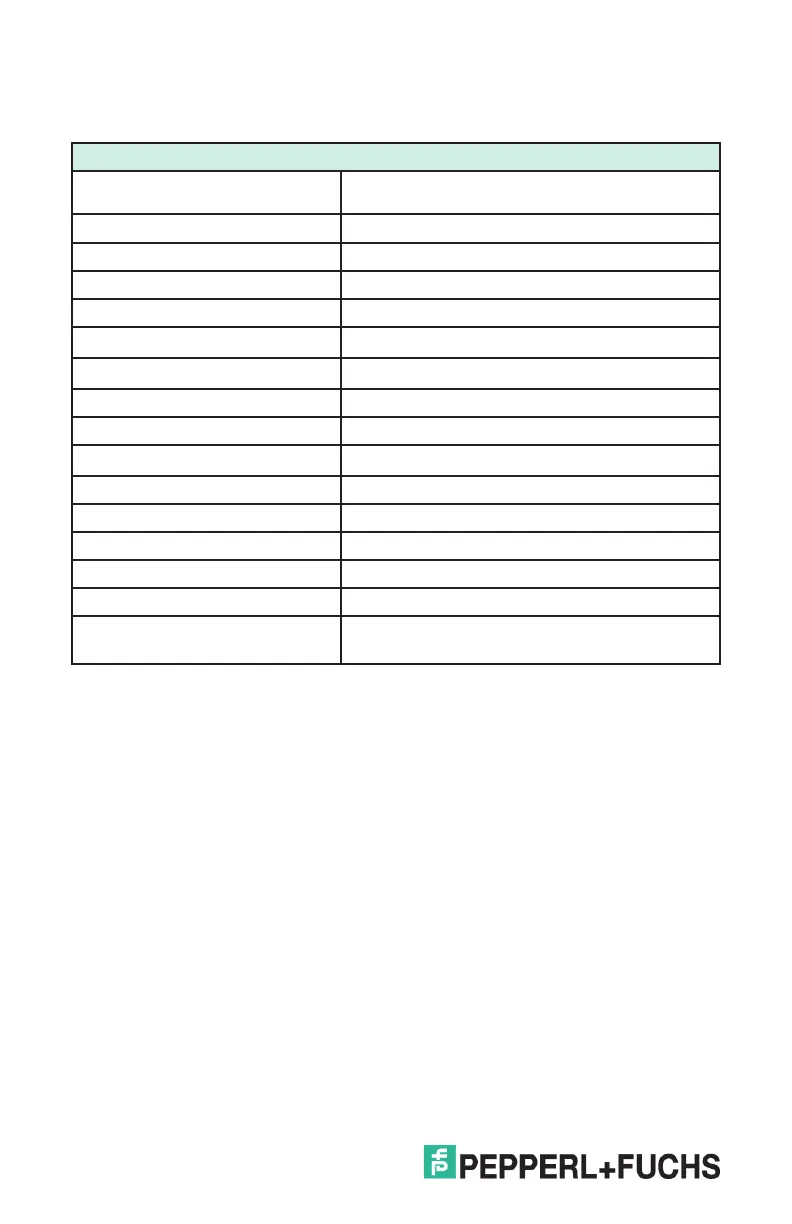

Functional safety related parameters*

Safety function

Relay output closed only when sensors activated by

appropriate target

Safe state

Relay output open

Standards/regulations ISO 13849-1 :2015/UL 508

Performance level acc. to ISO 13849-1 PL d

Structure acc. to ISO 13849-1 Category 3

MTTF

d

(years)

75850

DC

d

98.6 %

PFH 2.06 x 10E

-7

CCF

5 %

T

M

(years)

20

Pollution degree

2

Over-voltage category

(OC) II

Rated insulation voltage 250 V

Protection degree IP20, Class 1 “indoor use only”

Housing material 304 stainless steel

Internal hardware diagnostic fault

detection

< 4 s

*The following assumptions were made during the failure modes, eects, and diagnostic analysis (FMEDA) of the

FYQLA1-140R-3:

• Failure rates are constant, wear out mechanisms are not included.

• Failure rates are based on the Siemens standard SN29500.

• Power supply failures are not included in the FMEDA, a loss of power introduces the safe state.

• It was assumed that the appearance of a safe error (e. g., output in safe state) would be repaired within 8

hours (e. g., remove sensor burnout).

• During the absence of the device for repairing, measures have to be taken to ensure the safety function (for

example: substitution by an equivalent device).

• The stress levels are average for an industrial environment and can be compared to the Ground Fixed

Classication of MIL-HDBK-217F. Alternatively, the assumed environment is similar to IEC 60654-1 Class C

(sheltered location) with temperature limits within the manufacturer’s rating and an average temperature over

a long period of time of 40 °C. Humidity levels are assumed within manufacturer’s rating. For a higher average

temperature of 60 °C, the failure rates should be multiplied with an experience based factor of 2.5. A similar

multiplier should be used if frequent temperature uctuation must be assumed.

Product specications (cont.)

Loading...

Loading...