Functional Safety KCD2-UT2-(Ex)1, HiC2081

Operation

2018-02

25

5.3.2 Resistance Thermometer Input (RTD)

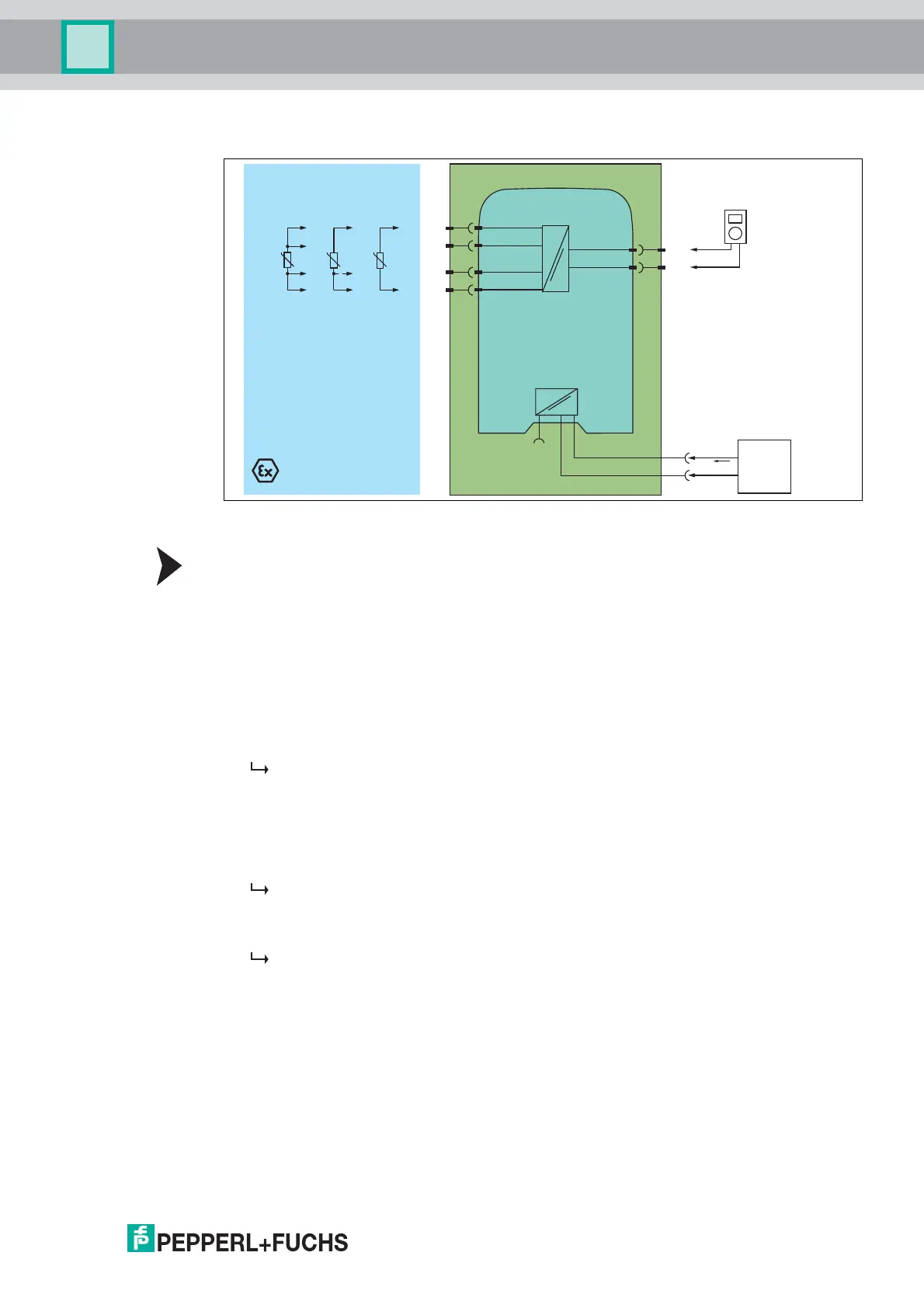

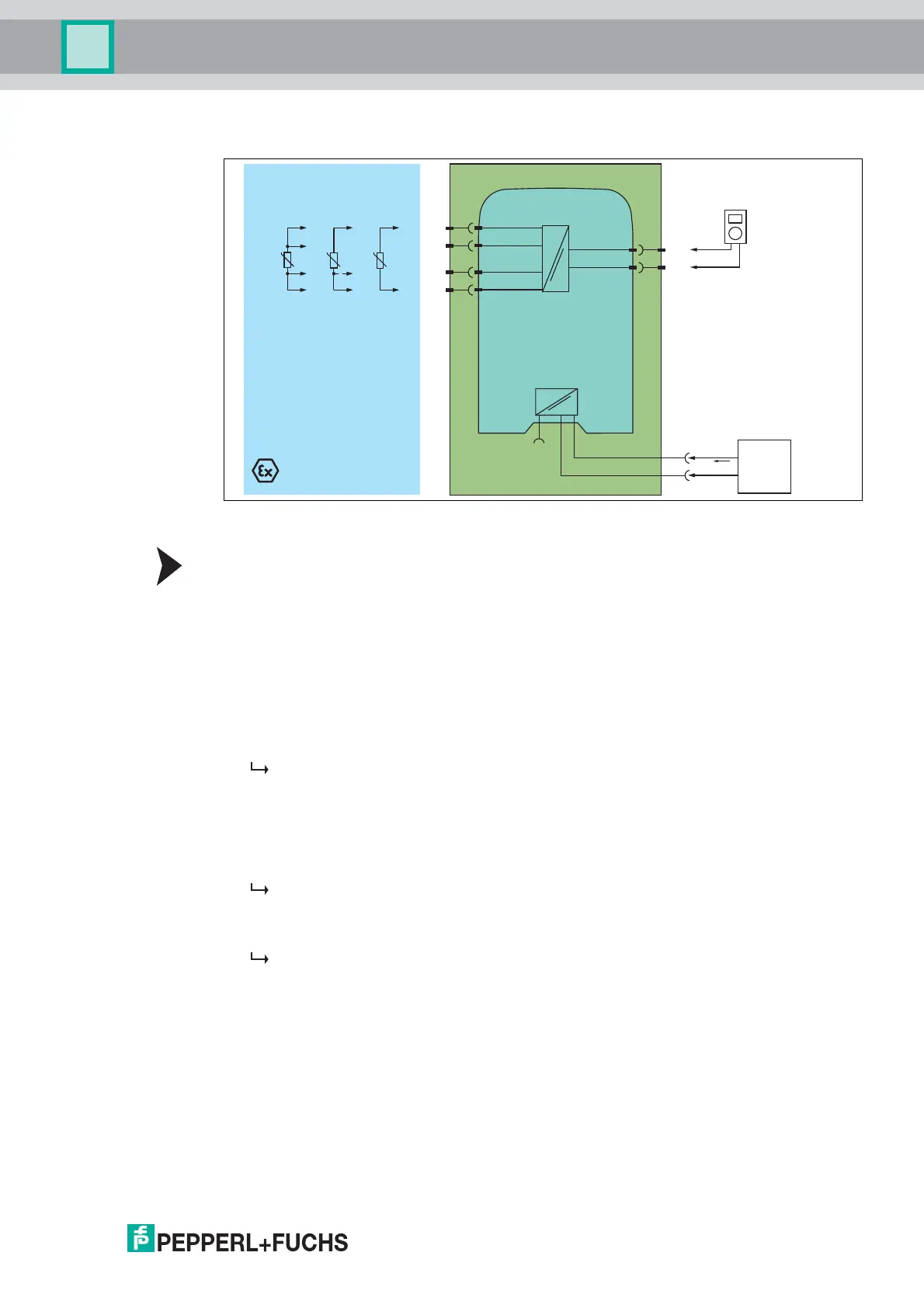

Figure 5.6 Proof test set-up for HiC2081 with resistance thermometer input (RTD)

Proof Test Procedure for Resistance Thermometer Input

1. Connect a RTD simulator, depending on the application.

• for 4-wire connection: terminals 1, 2, 5 and 4

• for 3-wire connection: terminals 1, 5 and 4

• for 2-wire connections: terminals 1 and 4

2. Connect the digital multimeter to the terminals 11 and 14.

3. Set the RTD simulator sequentially to the temperature values

representing 4 mA, 12 mA, 20 mA at the output.

4. Measure the output current.

The proof test is passed if the following values are measured at the output

1

:

– for the 4 mA application: 3,7 mA to 4,3 mA

– for the 12 mA application: 11,7 mA to 12,3 mA

– for the 20 mA application: 19.7 mA to 20.3 mA

5. Apply a short circuit between terminal 1 and 4. Do not remove the RTD simulator. Check if

a short circuit of the cold junction compensation is detected.

The red LED is flashing. The output behavior in the event of a fault depends on the

device configuration.

6. Remove the RTD simulator. Check if a lead breakage is detected.

The red LED is flashing. The output behavior in the event of a fault depends on the

device configuration.

7. Set the device back to the original settings after the test.

11

14

1

2

5

4

HiC2081

Termination Board

Zone 0, 1, 2

Fault

+

-

+

SL2

5a

1a

-

1b

5b

SL1

8a

7a

Multimeter

(mA)

T

T

T

Supply +

Supply -

24 V DC

Power

supply

I supply

Supply

Bus

1

Additionally the loop diagnosis shall be tested to prove that the fault signalling via the current output is working

correctly. The output current in the event of a failure depends on the device configuration. Please record this

configuration and the resulting expected fault signalling current in the test report. Example: if downscale is

configured, 2.0 mA ±1 % must be measured in the event of a failure. The red LED must be flashing.

Loading...

Loading...