SAFETY MANUAL SIL KFD2-UT2-(EX)*, HID2082

Proof Test

2011-09

15

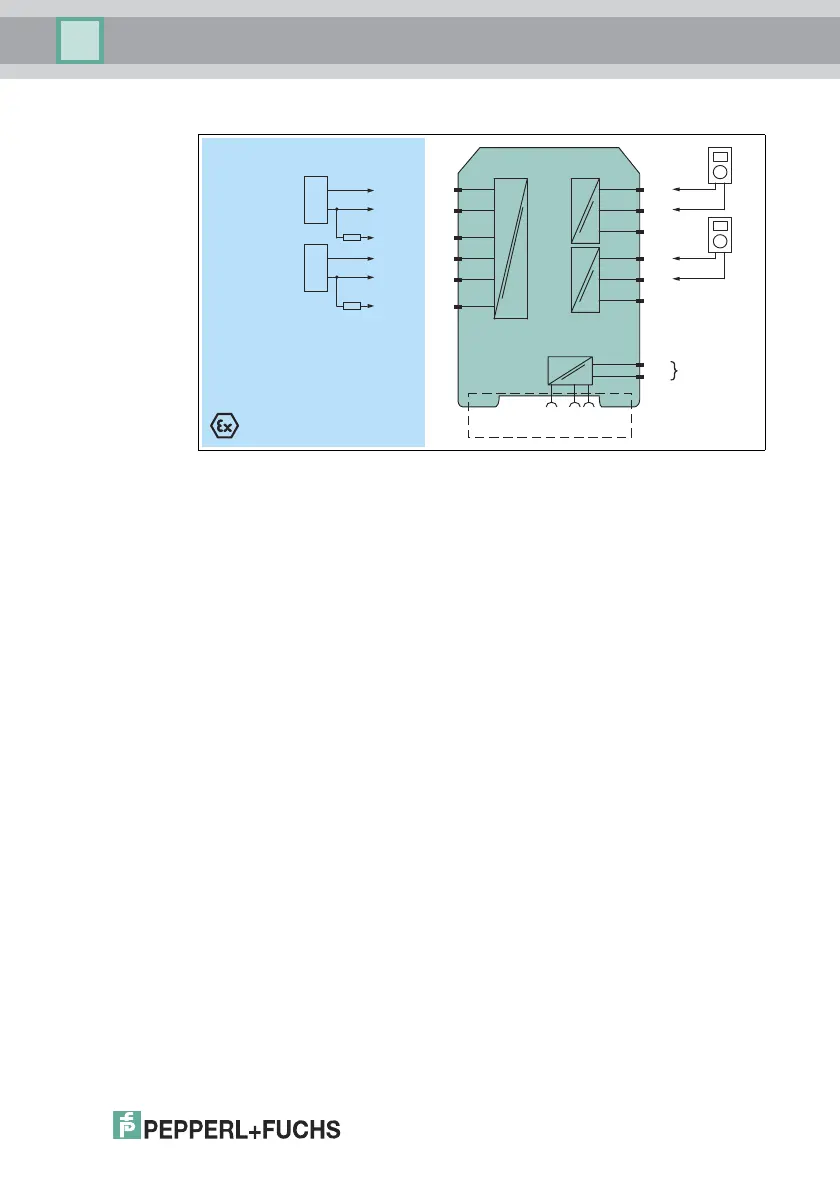

Thermocouple Input (TC)

Figure 4.1 Example proof test set-up for KFD2-UT2-(Ex)* (TC)

Usage in Zone 0, 1, 2/Div. 1, 2 only for KFD2-UT2-Ex1 and KFD2-UT2-Ex2

1-channel versions KFD2-UT2-1 and KFD2-UT2-Ex1 have only one channel.

Additional set up: 110 Ω fixed resistor

1. Connect TC simulator to the input terminals 1+ and 2- (channel I) and

4+ and 5- (channel II).

2. Connect current meter/digital multimeter (DMM) to the current output

terminals 7 and 8 (channel I) and 10 and 11 (channel II).

3. Set compensation/reference temperature in the simulator to 26 °C.

4. Connect a 110 Ω fixed resistor (0.1 % accuracy) to terminals 2 and 3

(channel I) and 5 and 6 (channel II) (instead of the special sensor for internal

compensation).

5. Set the TC simulator sequentially to the temperature values

representing 4 mA, 12 mA, 20 mA and measure the output current.

6. Proof test is passed if the measured output values are within 2 % of the output

span. This means:

• 3.7 mA ... 4.3 mA

• 11.7 mA ... 12.3 mA

• 19.7 mA ... 20.3 mA

7. Remove the 110 Ω resistor from terminals 2 and 3 (channel I) and 5 and 6

(channel II), to check if the lead breakage of the CJC is monitored. The red

LED must be blinking. The output behaviour in the event of a failure depends

on the device configuration.

This test is also applicable if external compensation (setting of a fixed

compensation temperature in the module) is used in the application. Adapt

CJC value in the simulator during step 3 accordingly.

KFD2-UT2-Ex2

Zone 2

Div. 2

Zone 0, 1, 2

Div. 1, 2

2

3

1

5

6

4

24 V DC

14+

15-

Power Rail

24 V DCERR

7

9-

8+

10

12-

11+

mA

mA

110Ω

TC

Sim.

110Ω

TC

Sim.

Loading...

Loading...