1/01 E Service Instructions 29

Start-Up

For reasons of fire precautions,

the machine is supplied with an

empty oil tank.

When filling in fresh hydraulic oil,

follow the instructions given un-

der "Hydraulic Oil Change" in the

Operating Instructions manual.

For oil grades to be used, refer to

"Lubricants" in the Operating In-

structions manual.

When starting up the system, first

check whether the clamp comes

down by pressing the pedal and

using the "pre-clamping" func-

tion. If the movement is not

smooth, or if the clamp does not

touch down on the cutting table,

the hydraulic system must be

ventilated. This is done automati-

cally by triggering several cuts

with the knife pushbuttons and

the clamping pressure (VD3) set

to minimum.

Check again by using the "pre-

clamping" function. Otherwise,

proceed as described above.

VD2

With the aid of the VD2 acting as

acceleration or fast-speed valve,

the clamp fast speed is regu-

lated. The clamp should move

down freely. For pre-clamping, it

must be possible to stop and start

it at any position and should, how-

ever, smoothly touch down onto

the cutting table. Too high a clamp

speed may cause damage to the

machine.

Adjust as follows:

• Slacken the lock nut.

• Gently readjust the setting

spindle

clockwise = to speed up;

anticlockwise = to slow down.

• Tighten the lock nut.

VD3

The clamping pressure valve is

set to the maximum clamping

pressure required for the respec-

tive machine sizes. Changing the

setting is not necessary and may

cause damage to the machine.

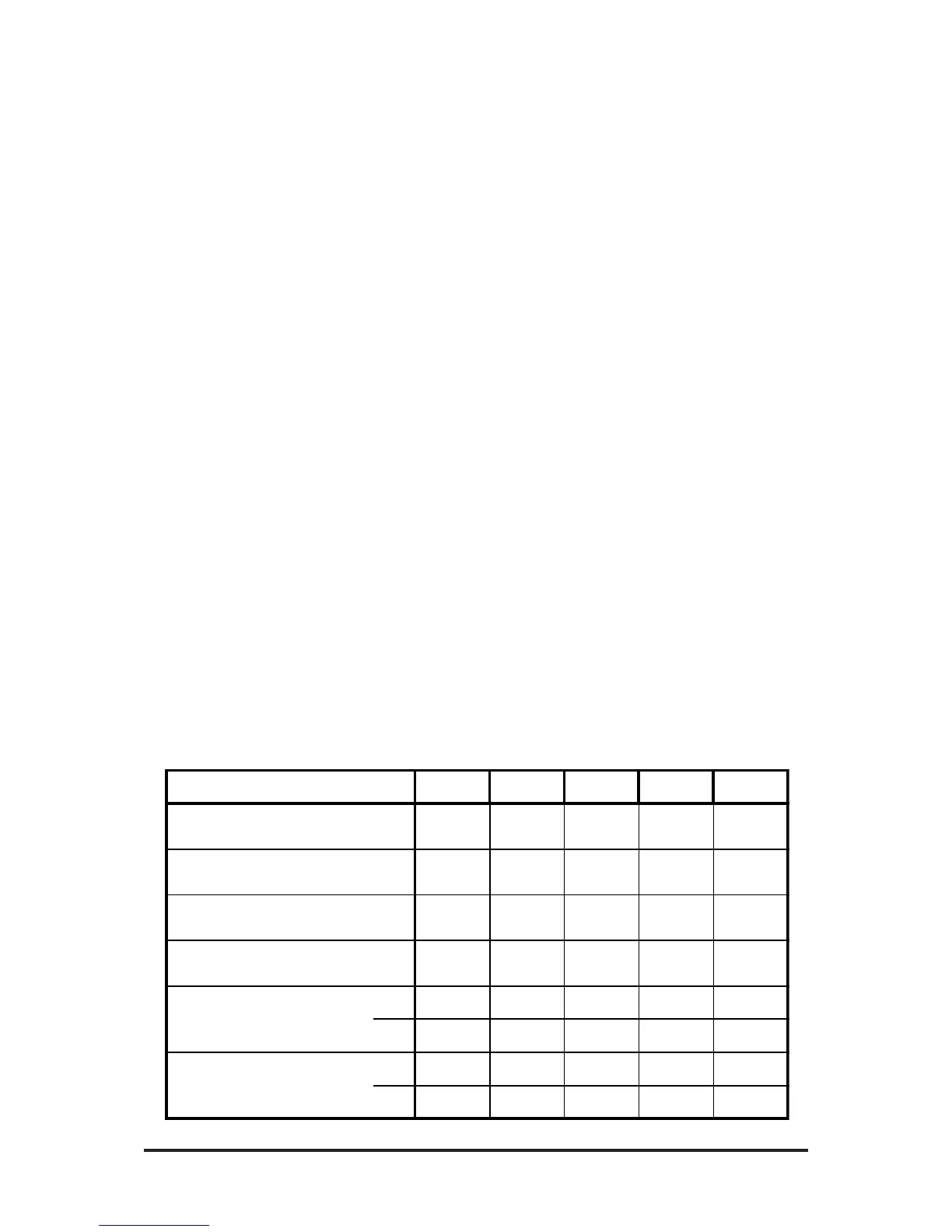

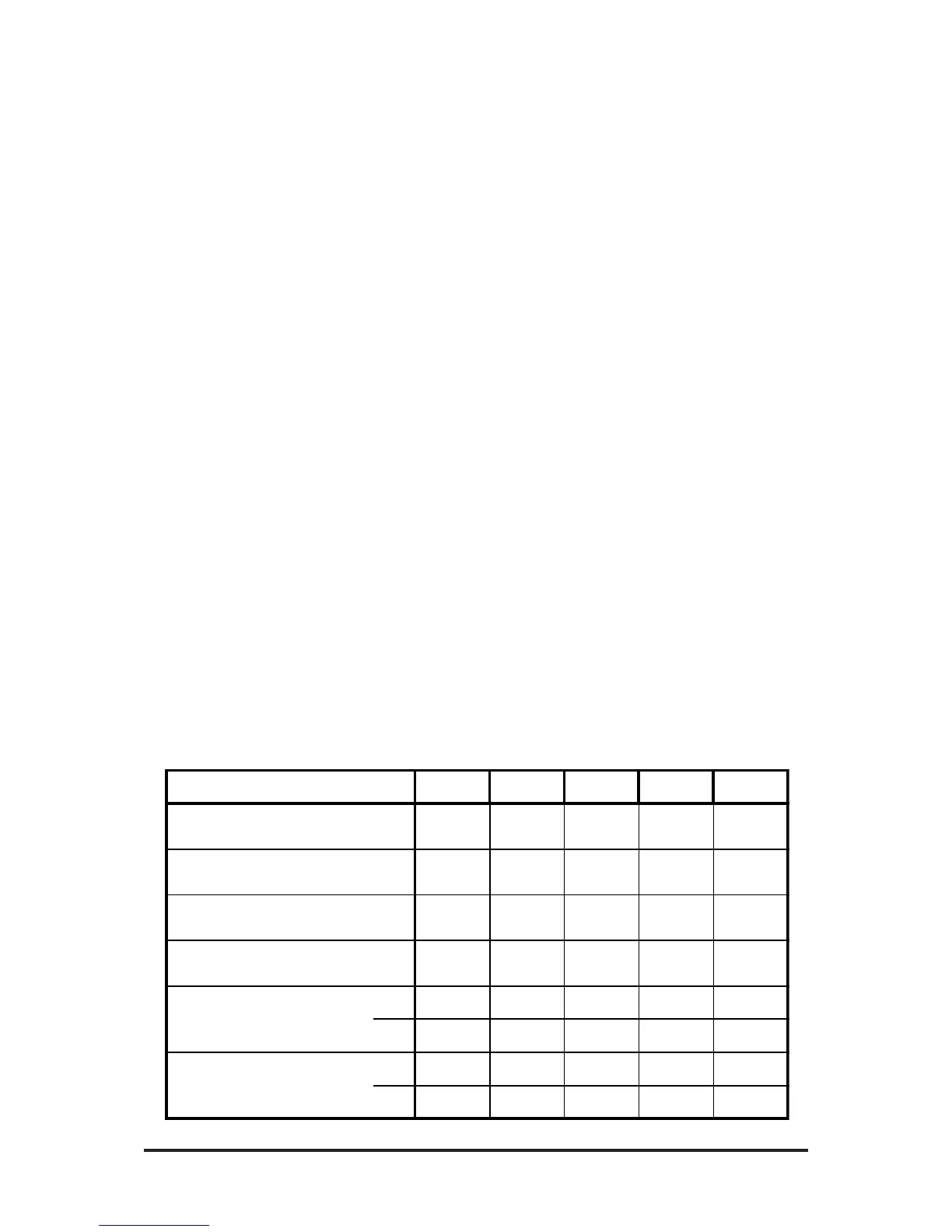

Fig. 35

Hydraulic Clamping System

Settings (MPa)

Important!

Insufficient alignment of the

machine at its place of installation

as well as canting of the clamp

draw rods may adversely affect

free traveling of the clamp. The

clamp is moved up by compres-

sion or tension springs.

Adjusting the

Hydraulic Clamping

System

If some readjustment of the pres-

sure-relief valves should be nec-

essary, perform the adjustment

in a gentle way and observe the

fol-lowing:

VD1, VD1.1

For safety reasons, these valves

must not be readjusted, as they

are set to the pre-clamping force

specified in prEN 1010. Increas-

ing the pressure bears the haz-

ard of injuries to the fingers or

hands of the operator during pre-

clamping.

Machine Size 76 92 115 132 168

Free Circulation Test Point M1 0,25-0,35 0,25-0,35 0,25-0,35 0,25-0,35 0,25-0,35

VD1, VD1.1 Test Point M1 1,5 2,5 1,5-1,8 1,5-1,8 2,5

Max. pre-clampimg force (N) acc. to

prEN 1010

300 300 300 300 500

VD2 Test Point M1 1,8 2,8 2 2 2,8

VD3

min. 0,18 0,29 0,2 0,2 0,3

max. 13 15,5 12 12 16

Clamping Force (kN)

min. 2 2 3 3 3,5

max. 25 30 45 45 60

Loading...

Loading...