Do you have a question about the PerkinElmer PINAACLE 900 Series and is the answer not in the manual?

| Wavelength Range | 190 - 900 nm |

|---|---|

| Category | Atomic Absorption Spectrometer |

| Model | PINAACLE 900 Series |

| Type | Laboratory Equipment |

| Optical System | Double Beam |

| Atomization | Flame, Graphite Furnace |

| Flame Types | Air-Acetylene, Nitrous Oxide-Acetylene |

| Correction System | Deuterium Background Correction |

| Bandwidth | 0.1, 0.2, 0.5, 1.0, 2.0 nm |

Key safety information and general precautions for operating the instrument.

Lab conditions for instrument operation and electrical safety practices to prevent hazards.

Precautions for safe handling of chemicals, gases, and proper waste disposal procedures.

Awareness and precautions for UV radiation, magnetic fields, and high temperatures.

Requirements for installation location, temperature, humidity, and physical space.

Specifications for line power, noise, conditioners, UPS, and fume ventilation.

Requirements for gas supplies, connections, cylinders, and safety.

Purity and pressure specifications for furnace and flame gases.

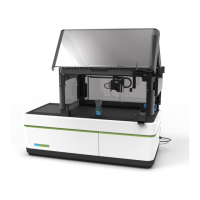

Introduction to the spectrometer system, concept, features, and components.

Major components, control methods, and accessories of the PinAAcle 900 system.

Description of burner assembly, gas connections, and cooling system details.

Detailed specifications for atomizers, background correction, and data handling.

Safely unpacking the instrument, inspecting shipment, and preparing the site.

Instructions for connecting gas supplies, electrical power, computer, and printer.

Procedures for installing cooling, drain systems, nebulizer, autosampler, and sample capillary.

Procedures for safely relocating and reinstalling the instrument.

Procedures for powering on the system and installing lamps.

Configuring the system for flame atomization, including burner setup and safety checks.

Configuring the system for furnace atomization, including cover locking and analysis setup.

General procedures, cleaning, periodic checks, and safety guidelines.

Procedures for burner head, drain system, and O-ring maintenance.

Changing filters, fuses, and servicing optical components.

Procedures for maintaining graphite tubes, contacts, windows, and furnace components.

Routine autosampler care and ordering replacement parts.

Solutions for problems with spectrometer, lamps, and computer communication.

Troubleshooting flame ignition, stability, and burner head issues.

Solutions for furnace operation, autosampler functionality, and graphite tube issues.

Troubleshooting for flame, furnace, and flow injection techniques, including sensitivity and signal problems.