6. Install a new diaphragm and plate (4) for the

breather assembly into the cavity (7) of the valve

mechanism cover or the spacer (5) for

turbocharged engines.

7. Install a new spring (3).

8. Install the breather cover (2) and the four screws

(1). Tighten the screws.

i07819538

Engine Mounts - Inspect

Note: The engine mounts may not have been

supplied by Perkins. Refer to the Original Equipment

Manufacturer (OEM) information for further details on

the engine mounts and the correct bolt torque.

Inspect the engine mounts for deterioration and for

correct bolt torque. Excessive engine vibration can

be caused by the following conditions:

• Incorrect mounting of the engine

• Deterioration of the engine mounts

• Loose engine mounts

Any engine mount that shows deterioration should be

replaced. Refer to the OEM information for the

recommended torques.

When the engine mounts are supplied by Perkins the

maintenance procedure will be supplied in the

Disassembly and Assembly manual for your engine.

i06812544

Engine Oil Level - Check

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

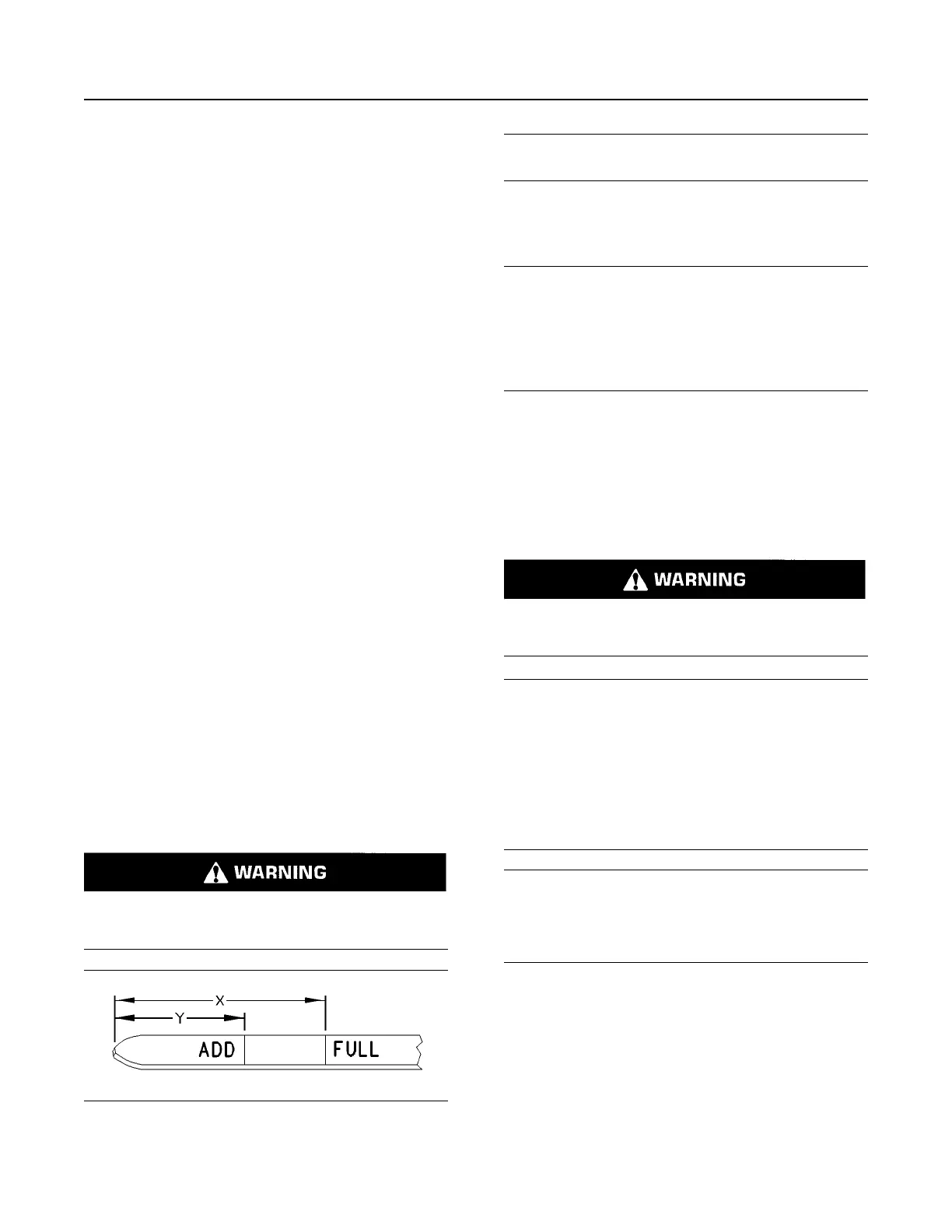

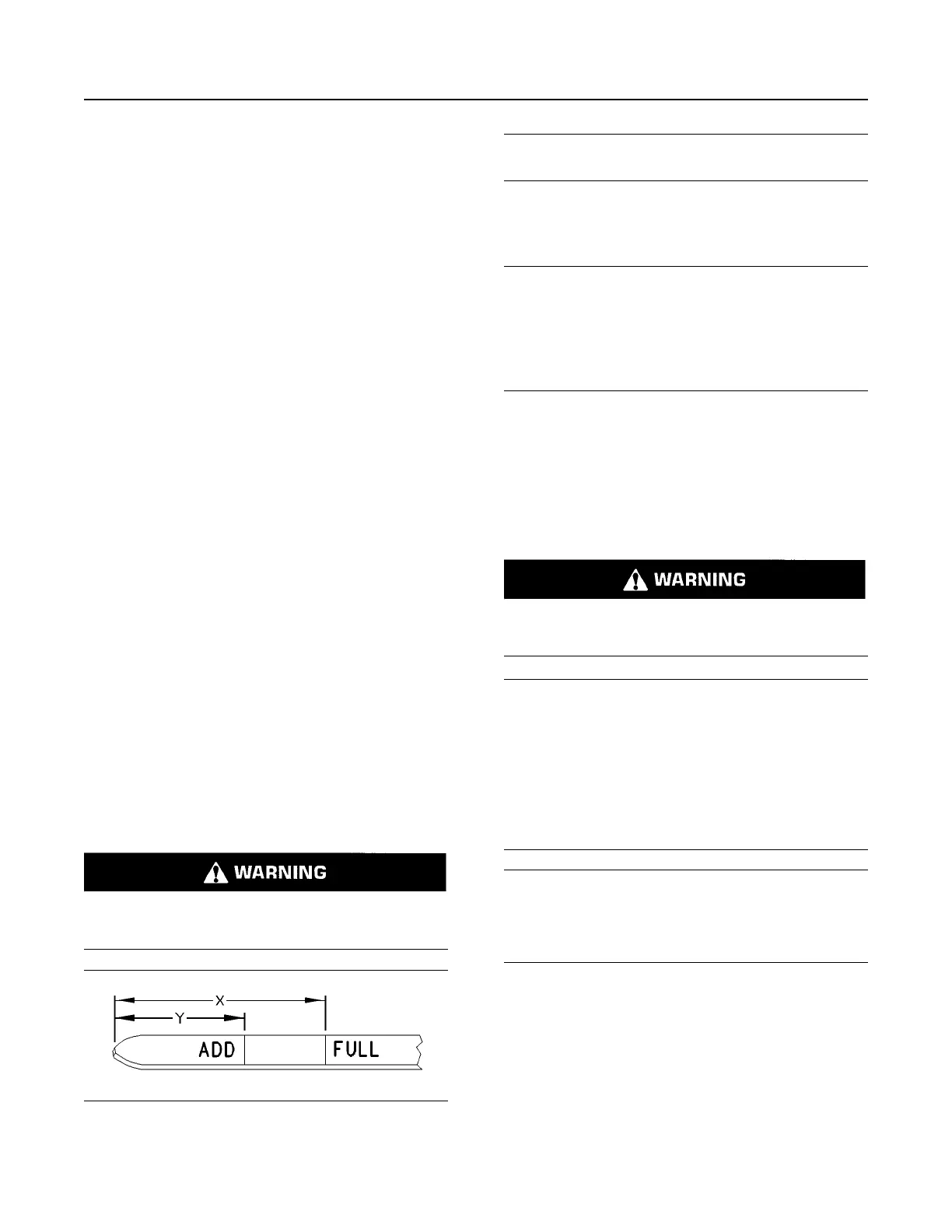

Illustration 42 g00110310

(Y) “ADD” mark. (X) “FULL” mark.

NOTICE

Perform this maintenance with the engine stopped.

1. Maintain the oil level between “ADD” mark (Y) and

“FULL” mark (X) on oil level gauge (1). Do not fill

the crankcase above “FULL” mark (X).

NOTICE

Operating your engine when the oil level is above the

“FULL” mark could cause your crankshaft to dip into

the oil. The air bubbles created from the crankshaft

dipping into the oil reduces the oil's lubricating char-

acteristics and could result in the loss of power or en-

gine failure.

2. Remove the oil filler cap and add oil, if necessary.

Clean the oil filler cap. Install the oil filler cap.

i08037360

Engine Oil and Filter - Change

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product.

Be prepared to collect the fluid with suitable contain-

ers before opening any compartment or disassem-

bling any component containing fluids.

Dispose of all fluids according to local regulations

and mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Do not drain the oil when the engine is cold. As the oil

cools, suspended waste particles settle on the

bottom of the oil pan. The waste particles are not

removed with the draining cold oil. Drain the

crankcase with the engine stopped. Drain the

crankcase with the oil warm. This draining method

allows the waste particles that are suspended in the

oil to be drained correctly.

Failure to follow this recommended procedure will

cause the waste particles to be recirculated through

the engine lubrication system with the new oil.

68

SEBU7992-05

Maintenance Section

Engine Mounts - Inspect

Loading...

Loading...