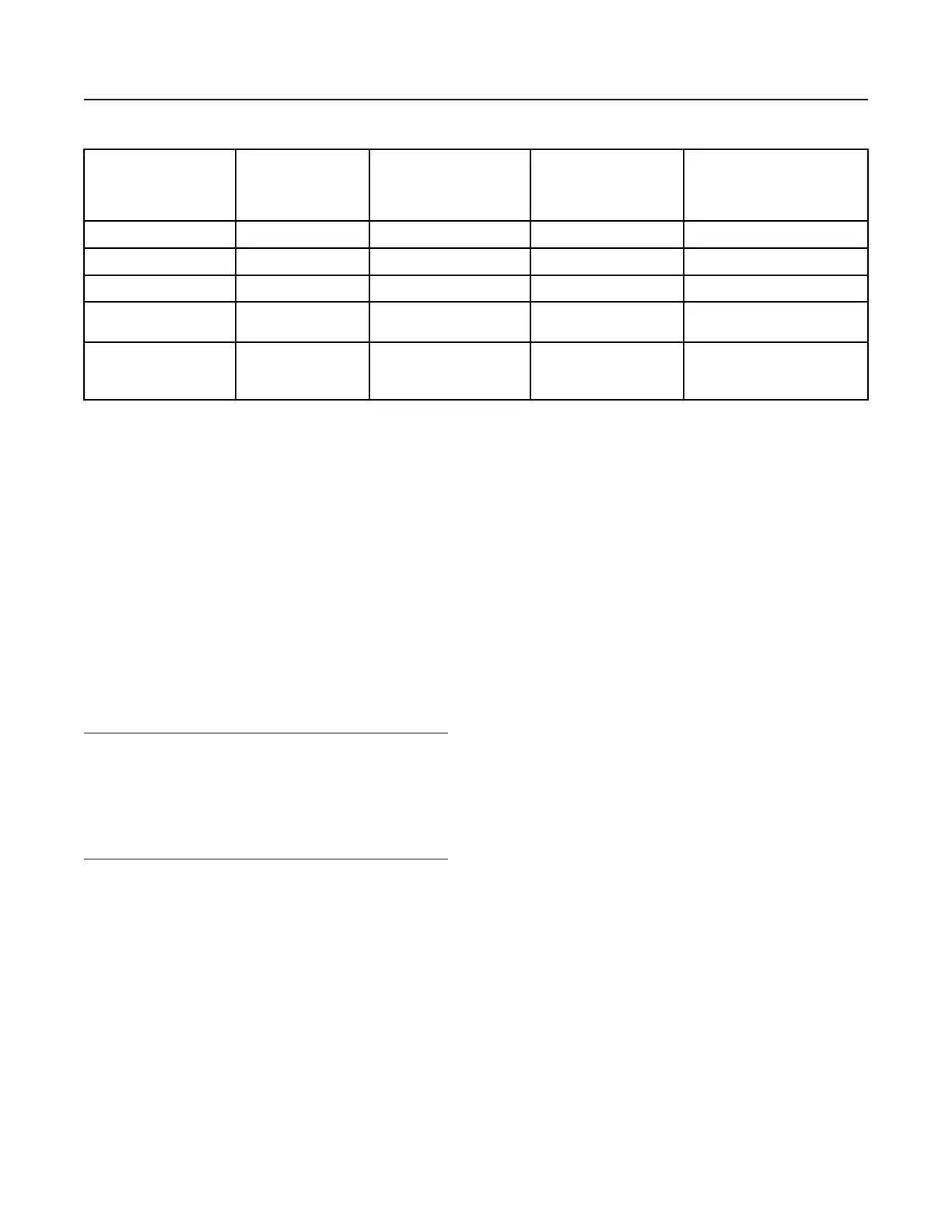

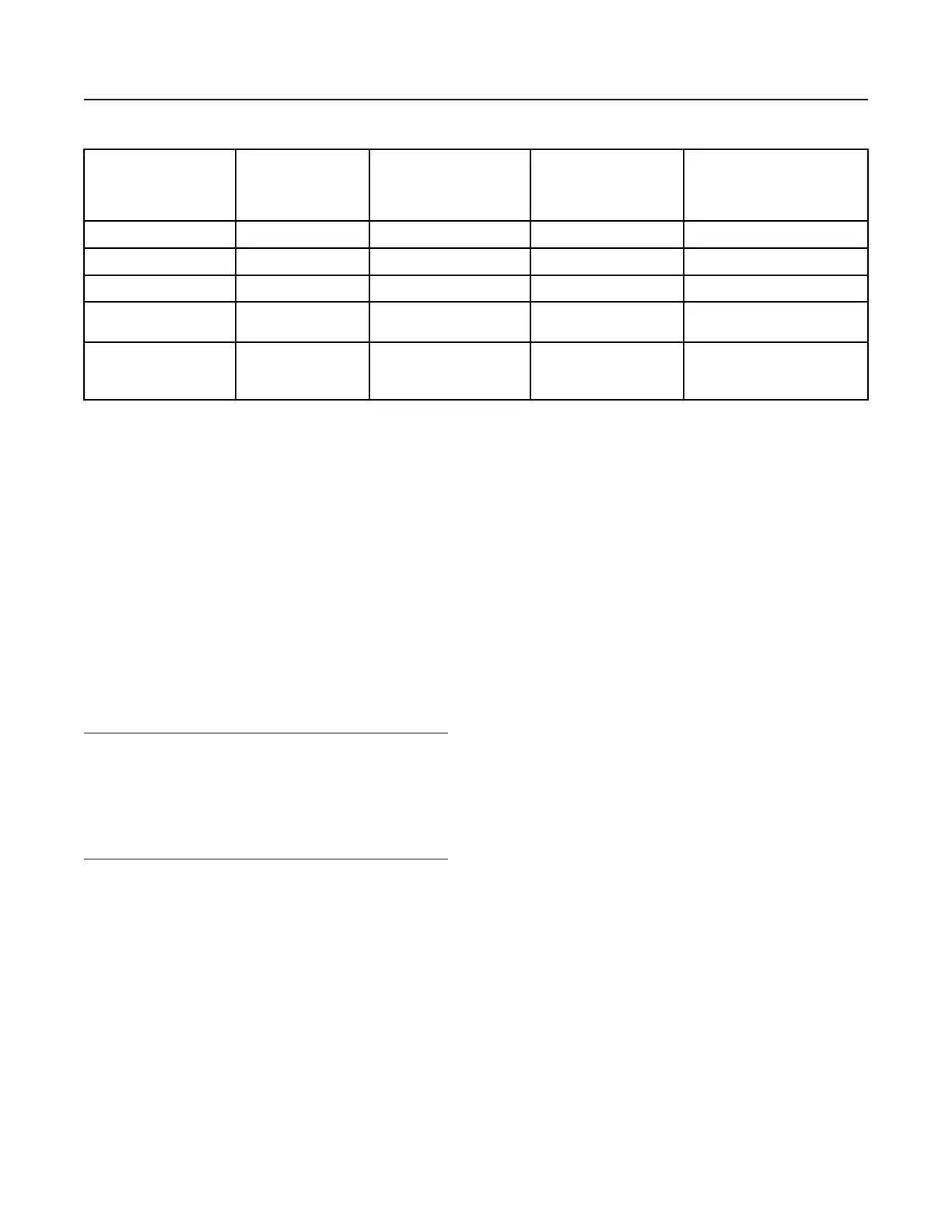

(Table 24, contd)

Kinematic Viscosity

(5)

“MM”

2

“/S (cSt)” The viscosity of the fuel that

is delivered to the fuel injec-

tion pump. “1.4 minimum/

4.5 maximum”

D445 “ISO”3405

Water and sediment % weight 0.1% maximum D1796 “ISO”3734

Water % weight 0.1% maximum D1744 No equivalent test

Sediment % weight 0.05% maximum D473 “ISO”3735

Gums and Resins

(6)

mg/100mL 10 mg per 100 mL

maximum

D381 “ISO”6246

Lubricity corrected wear

scar diameter at 60 °C

(140 °F).

(7)

mm

0.46 maximum D6079 “ISO”12156-1

(1)

This specification includes the requirements for Ultra Low Sulfur Diesel (ULSD). ULSD fuel will have ≤ 15 ppm (0.0015%) sulfur. Refer to

“ASTM D5453”, “ASTM D2622”, or “ISO 20846, ISO 20884” test methods. This specification includes the requirements for Low Sulfur Diesel

(LSD). LSD fuel will have ≤500 ppm (0.05%) sulfur. Refer to following:“ASTM 5453, ASTM D2622”, “ISO 20846” and “ISO 20884 test meth-

ods”. Refer to Tables 25 and 26 .

(2)

A fuel with a higher cetane number is recommended in order to operate at a higher altitude or in cold weather.

(3)

“Via standards tables, the equivalent API gravity for the minimum density of 801 kg / m

3

(kilograms per cubic meter) is 45 and for the maxi-

mum density of 876 kg / m

3

is 30”.

(4)

Regional regulations, national regulations or international regulations can require a fuel with a specific sulfur limit. Consult all applicable regu-

lations before selecting a fuel for a given engine application. Perkins fuel systems and engine components can operate on high sulfur fuels in

territories that are non-emissions regulated. Fuel sulfur levels affect exhaust emissions. High sulfur fuels also increase the potential for corro-

sion of internal components. Fuel sulfur levels above 0.5% may significantly shorten the oil change interval. For additional information, refer

to this manual, “Fluid recommendations (General lubricant Information)”.

(5)

The values of the fuel viscosity are the values as the fuel is delivered to the fuel injection pumps. Fuel should also meet the minimum viscos-

ity requirement and the fuel should meet the maximum viscosity requirements at 40 °C (104 °F) of either the “ASTM D445” test method or

the “ISO 3104” test method. If a fuel with a low viscosity is used, cooling of the fuel may be required to maintain 1.4 cSt or greater viscosity at

the fuel injection pump. Fuels with a high viscosity might require fuel heaters in order to lower the viscosity to 4.5 cSt at the fuel injection

pump.

(6)

Follow the test conditions and procedures for gasoline (motor).

(7)

The lubricity of a fuel is a concern with low sulfur and ultra low sulfur fuel. To determine the lubricity of the fuel, use the “ISO 12156-1 or ASTM

D6079 High Frequency Reciprocating Rig (HFRR)” test. If the lubricity of a fuel does not meet the minimum requirements, consult your fuel

supplier. Do not treat the fuel without consulting the fuel supplier. Some additives are not compatible. These additives can cause problems in

the fuel system.

NOTICE

Operating with fuels that do not meet the Perkins rec-

ommendations can cause the following effects: Start-

ing difficulty, poor combustion, deposits in the fuel

injectors, reduced service life of the fuel system, de-

posits in the combustion chamber and reduced serv-

ice life of the engine.

Diesel Fuel Characteristics

Perkins Recommendation

Cetane Number

Fuel that has a high cetane number will give a shorter

ignition delay. This will produce a better ignition

quality. Cetane numbers are derived for fuels against

proportions of cetane and heptamethylnonane in the

standard CFR engine. Refer to “ISO 5165” for the

test method.

Cetane numbers in excess of 45 are normally

expected from current diesel fuel. However, a cetane

number of 40 may be experienced in some territories.

The United States of America is one of the territories

that can have a low cetane value. A minimum cetane

value of 40 is required during average starting

conditions. A higher cetane value may be required for

operations at high altitudes or in cold weather

operations.

Fuel with a low cetane number can be the root cause

of problems during cold start.

Viscosity

Viscosity is the property of a liquid of offering

resistance to shear or flow. Viscosity decreases with

increasing temperature. This decrease in viscosity

follows a logarithmic relationship for normal fossil

fuel. The common reference is to kinematic viscosity.

This is the quotient of the dynamic viscosity that is

divided by the density. The determination of

kinematic viscosity is normally by readings from

gravity flow viscometers at standard temperatures.

Refer to “ISO 3104” for the test method.

SEBU8311-09

45

Maintenance Section

Fuel Specification

Loading...

Loading...