The viscosity of the fuel is significant because fuel

serves as a lubricant for the fuel system components.

Fuel must have sufficient viscosity in order to

lubricate the fuel system in both extremely cold

temperatures and extremely hot temperatures. If the

kinematic viscosity of the fuel is lower than 1.4 cSt at

the fuel injection pump damage to the fuel injection

pump can occur. This damage can be excessive

scuffing and seizure. Low viscosity may lead to

difficult hot restarting, stalling and loss of

performance. High viscosity may result in seizure of

the pump.

Perkins recommends kinematic viscosities of 1.4 and

4.5 mm2/sec that is delivered to the fuel injection

pump.

Density

Density is the mass of the fuel per unit volume at a

specific temperature. This parameter has a direct

influence on engine performance and a direct

influence on emissions. This determines the heat

output from a given injected volume of fuel. This is

generally quoted in the following kg/m at 15 °C

(59 °F).

Perkins recommends a value of density of 841 kg/m

in order to obtain the correct power output. Lighter

fuels are acceptable but these fuels will not produce

the rated power.

Sulfur

The level of sulfur is governed by emissions

legislations. Regional regulation, national regulations

or international regulations can require a fuel with a

specific sulfur limit. The sulfur content of the fuel and

the fuel quality must comply with all existing local

regulations for emissions.

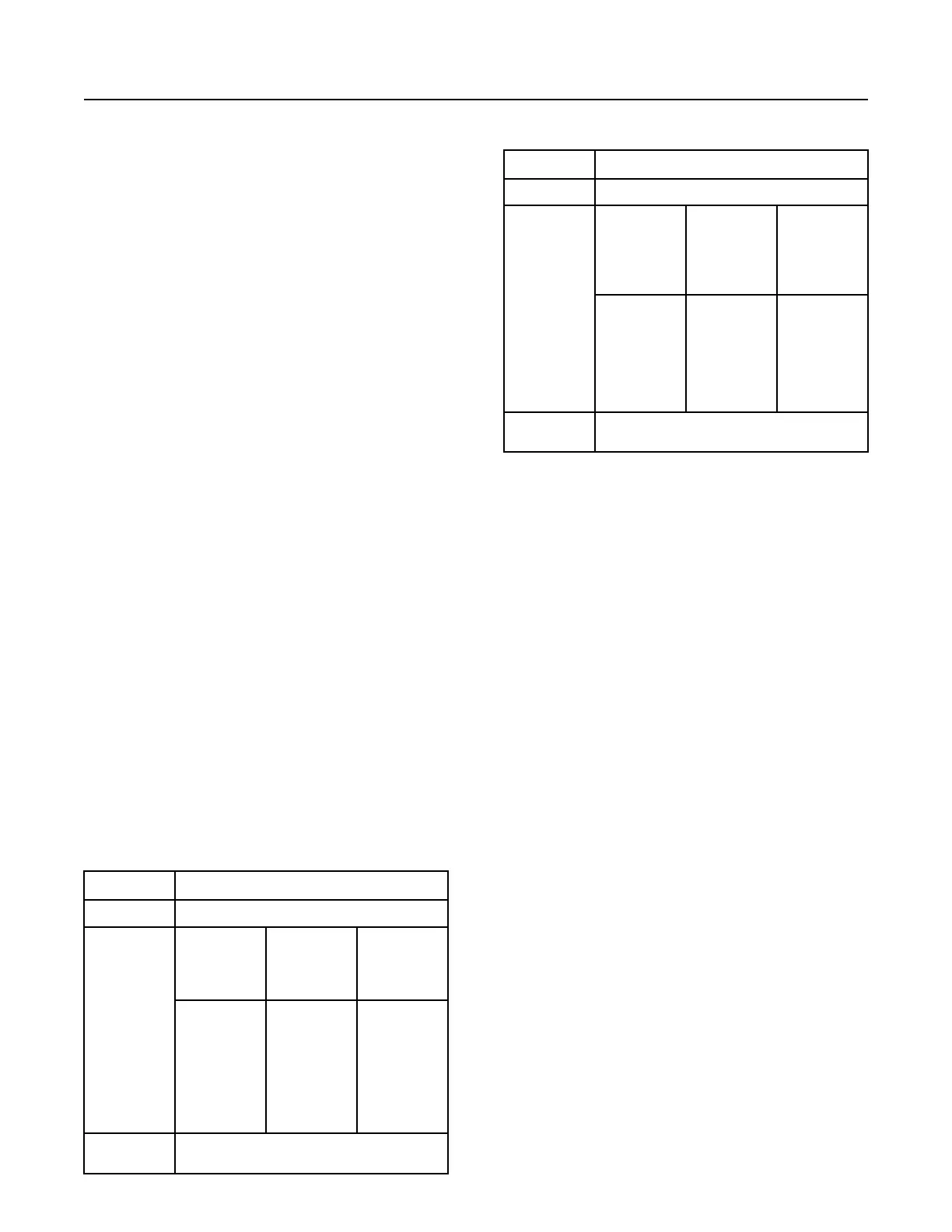

Tables 25 and 26 list the guidelines for the correct

sulfur level for specific territories. Consult all

applicable regulations before selecting the fuel for a

given engine application.

Table 25

Territory Fuel Requirements from 2007

EPA

Low Sulfur (500 ppm) maximum

EC

Sulfur/Power Low sulfur (300

ppm) maximum

for less than or

equal to 19 kW

Sulphur (1000

ppm) maximum

for greater than

19 kW

Models 402D-05 and

403D-07

403D-11,

403D-15,

403D-15T,

403D-17,

404D-15.

404D-22,

404D-22T and

404D-22TA

Non-Regulated

Territories

Sulfur limit of less than 4000 ppm

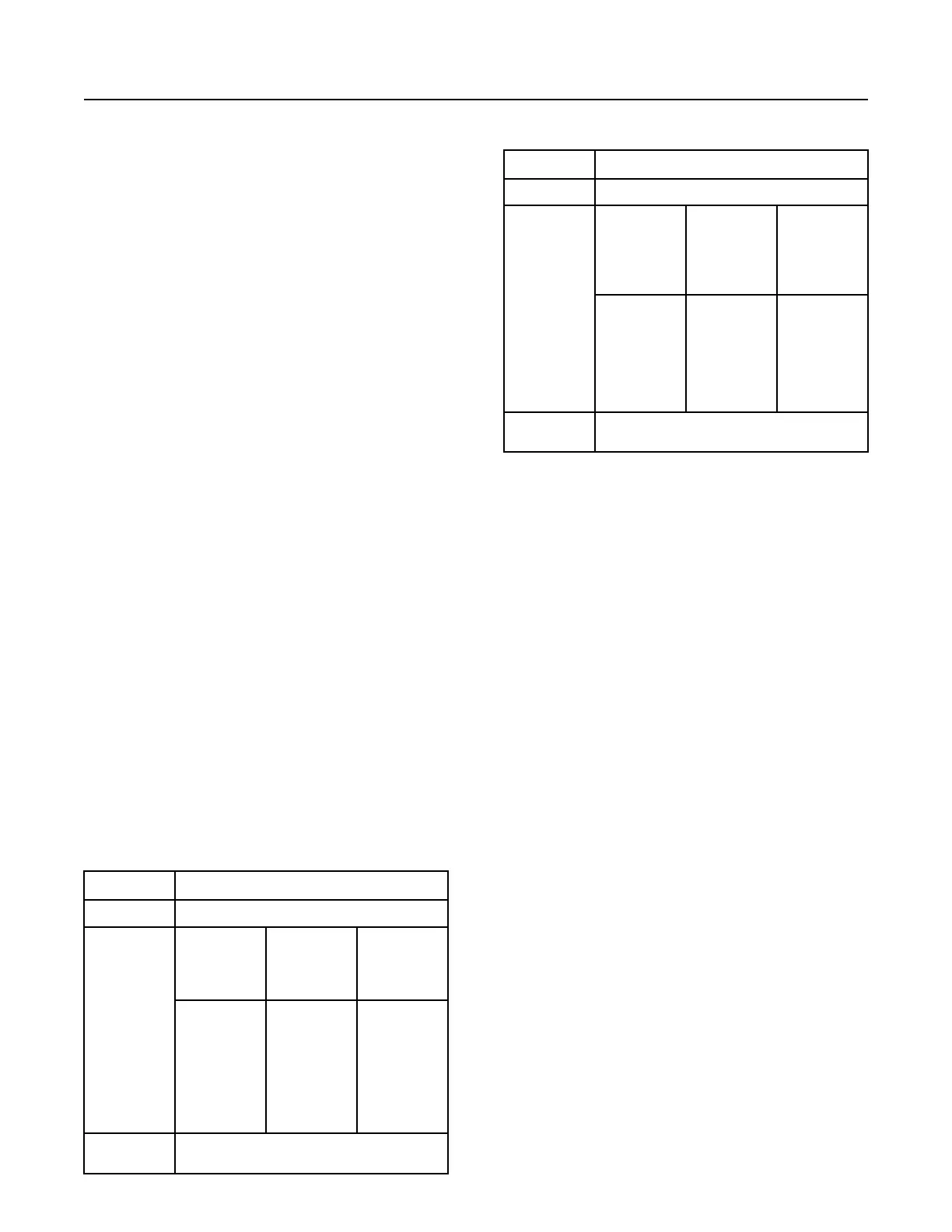

Table 26

Territory Fuel Requirements from 2010

EPA

Ultra Low Sulfur (15 ppm) maximum

EC

Sulfur/Power Ultra Low sul-

phur (10 ppm)

maximum for

less than or

equal to 37 kW

Low sulphur

(300 ppm)

maximum for

greater than 37

kW

Models 402D-05,

403D-07,

403D-11,

403D-15,

403D-15T,

403D-17,

404D-15

404D-22,

404D-22T and

404D-22TA

Non Regulated

Territories

Sulfur limit of less than 4000 ppm

By using the test methods “ASTM D5453, ASTM

D2622, or ISO 20846 ISO 20884”, the content of

sulfur in low sulfur diesel (LSD) fuel must be below

500 PPM 0.05%. By using the test methods “ASTM

D5453, ASTM D2622, or ISO 20846 ISO 20884”, the

content of sulfur in ultra low sulfur (ULSD) fuel must

be below 15 PPM 0.0015%. The lubricity of these

fuels must not exceed wear scar diameter of

0.46 mm (0.0181 inch). The fuel lubricity test must

be performed on a HFRR, operated at 60 °C

(140 °F). Refer to “ISO 12156-1 ”.

In some parts of the world and for some applications,

high sulfur fuels above 0.5% by mass might only be

available. Fuel with very high sulfur content can

cause engine wear. High sulfur fuel will have a

negative impact on emissions of particulates. High

sulfur fuel can be used provided that the local

emissions legislation will allow the use. High sulfur

fuel can be used in countries that do not regulate

emissions.

When only high sulfur fuels are available, it will be

necessary that high alkaline lubricating oil is used in

the engine or that the lubricating oil change interval is

reduced. Refer to this Operation and Maintenance

Manual, “Fliud Recommendations (Genernal

Lubrication Information)” for information on sulfur in

fuel.

Lubricity

This is the capability of the fuel to prevent pump

wear. The fluid's lubricity describes the ability of the

fluid to reduce the friction between surfaces that are

under load. This ability reduces the damage that is

caused by friction. Fuel injection systems rely on the

lubricating properties of the fuel. Until fuel sulfur limits

were mandated, the fuel's lubricity was generally

believed to be a function of fuel viscosity.

46

SEBU8311-09

Maintenance Section

Fuel Specification

Loading...

Loading...