The lubricity has particular significance to the current

low viscosity fuel, low sulfur fuel and low aromatic

fossil fuel. These fuels are made in order to meet

stringent exhaust emissions. A test method for

measuring the lubricity of diesel fuels has been

developed and the test is based on the HFRR

method that is operated at 60 °C (140 °F). Refer to

“ISO 12156 part 1 and CEC document F06-A-96” for

the test method.

Lubricity wear scar diameter of 0.46 mm

(0.0181 inch) MUST NOT be exceeded. The fuel

lubricity test must be performed on a HFRR,

operated at 60 °C (140 °F). Refer to “ISO 12156-1 ”.

Fuel additives can enhance the lubricity of a fuel.

Contact your fuel supplier for those circumstances

when fuel additives are required. Your fuel supplier

can make recommendations for additives to use and

for the proper level of treatment. Refer to “Fuel

Additive” for more information.

Distillation

This is an indication of the mixture of different

hydrocarbons in the fuel. A high ratio of light weight

hydrocarbons can affect the characteristics of

combustion.

Classification of the Fuels

Diesel engines have the ability to burn a wide variety

of fuels. These fuels are divided into four general

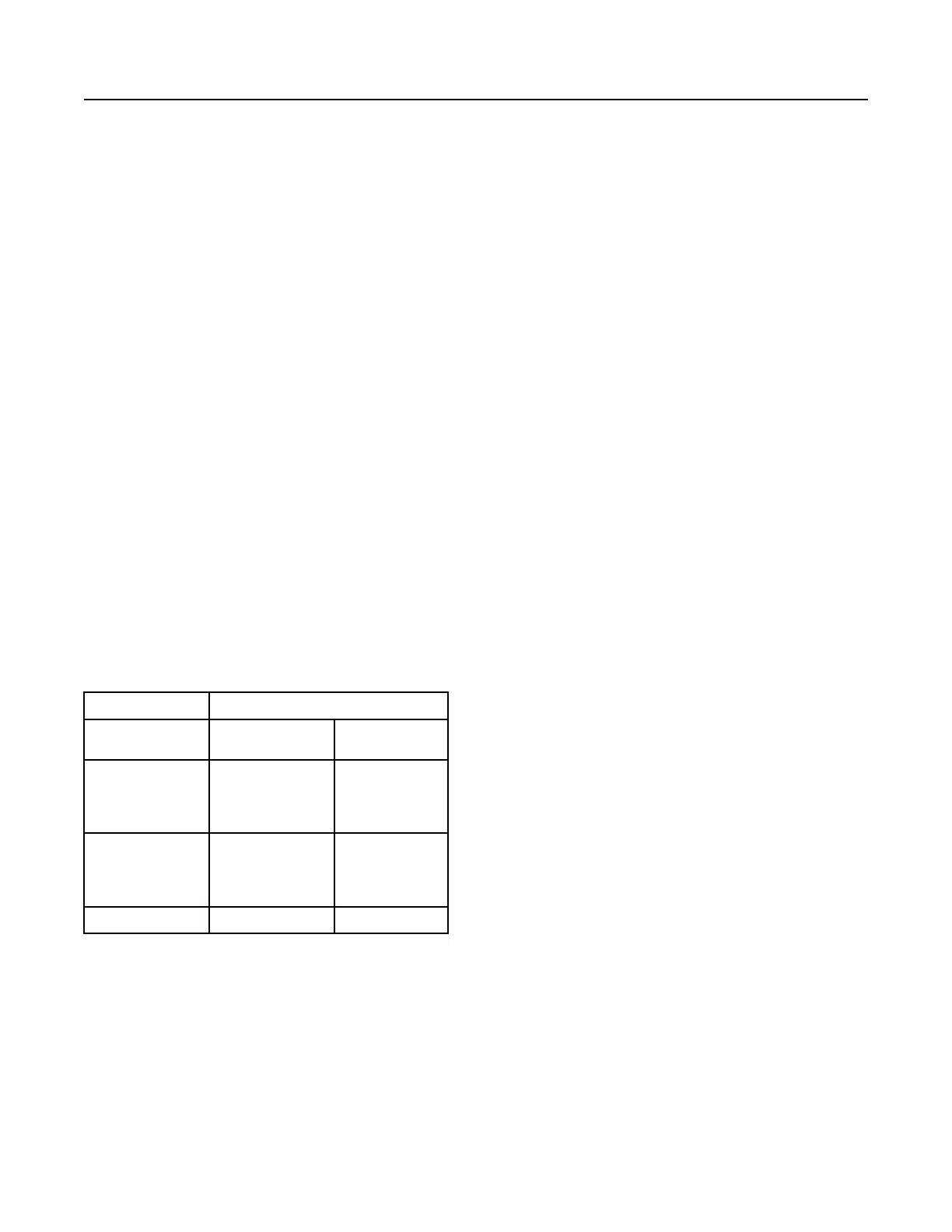

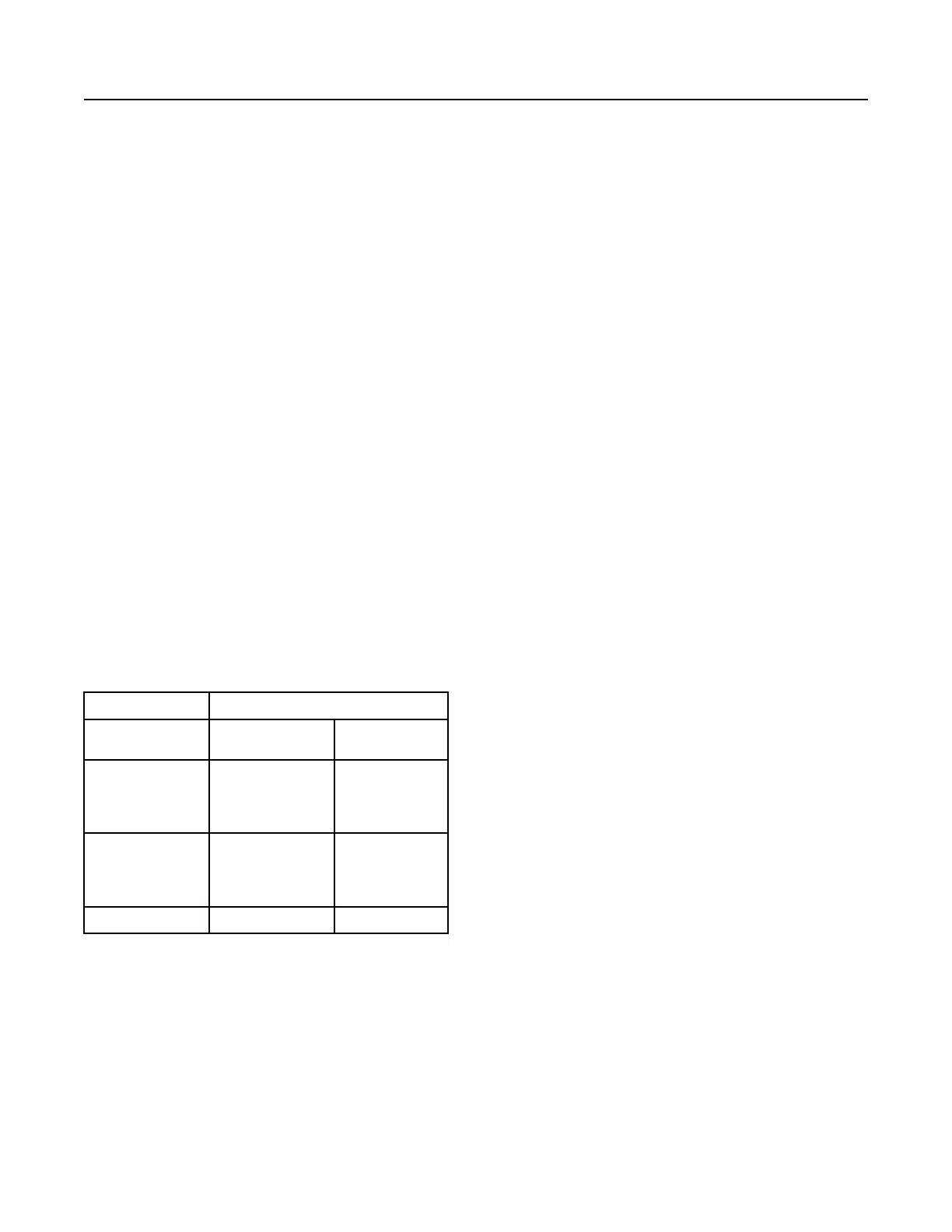

groups: Ref to table 27

Table 27

Fuel Groups Classification

Group 1 Preferred fuels Full life of the

Product

Group 2 Permissible fuels These fuels MAY

cause reduced en-

gine life and

performance

Group 3 Aviation fuels These fuels WILL

cause reduced en-

gine life and

performance

Group 4 Biodiesel

Group 1 Specifications (Preferred Fuels)

This group of fuel specifications is considered

acceptable:

• EN590 DERV Grade A, B, C, E, F, Class, 0, 1, 2, 3

and 4

• “ASTM D975”, Grade 2D S15 and Grade 2D S500

• “JIS K2204 Grades 1,2,3 and Special Grade 3”

This grade of fuel must meet the minimum lubricity

requirements that are stated in table 24 .

• “BS2869 Class A2” Off-Highway Gas Oil Red

Diesel

Note: BS2869 can only be used if the sulfur level

meets the specifications that are listed in tables 25

and 26 . An analysis of a sample of fuel must be

conducted in order to check the sulfur level.

Note: The use of LSD fuel and the use of ULSD fuel

is acceptable provided that the fuels meet the

minimum requirements that are stated in tables 24 ,

25 and 26 . The lubricity of these fuels must not

exceed wear scar diameter of 0.46 mm

(0.0181 inch). The lubricity test must be performed

on a HFRR, operated at 60 °C (140 °F). Refer to

“ISO 12156-1 ”. By using the test methods “ASTM

D5453, ASTM D2622, or ISO 20846 ISO 20884”, the

content of sulfur in LSD fuel must be below 500 PPM

0.05%. By using the test methods “ASTM D5453,

ASTM D2622, or ISO 20846 ISO 20884”, the content

of sulfur in ULSD fuel must be below 15 PPM

0.0015%.

Group 2 Specifications (Permissible

Fuels)

This group of fuel specifications is considered

acceptable, but these fuels MAY reduce the engine

life and performance.

• “ASTM D975”, Grade 1D S15 and Grade 1D S500

• “JP7 (MIL-T-38219)”

• “NATO F63”

Note: JP7 and NATO F63 can only be used if the

sulfur level meets the specifications that are listed in

tables 25 and 26 . An analysis of a sample of fuel

must be conducted in order to check the sulfur level.

Group 3 Specifications (Aviation Fuels)

This group of fuel specification must be used only

with the appropriate fuel additive. This fuel WILL

reduce engine life and performance.

• “NATO F34 (MIL-DTL-83133E)”

• “NATO F35 (MIL-DTL-83133E)”

• “NATO JP8 (MIL-DTL-83133E)”

• “NATO F-44 (MIL-DTL-5624U)”

• “NATO JP5 (MIL-DTL-5624U)”

• “Jet A (ASTM D1655)”

• “Jet A1 (ASTM D1655)”

SEBU8311-09

47

Maintenance Section

Fuel Specification

Loading...

Loading...