This document is printed from SPI². Not for RESALE

10. Start the engine. Refer to Operation and

Maintenance Manual, “Starting the Engine” for the

correct procedure. Refer to steps 10.a. to 10.d. for

the procedure for testing the air in fuel.

a. Run the engine a low idle speed.

b. Run the engine for 2 minutes. There should be

no air in the fuel flow through the sight tube.

Small bubbles that are spaced more than

2.5 cm (1.0 inch) are acceptable. Do not

manipulate the connections during the test for

the air in fuel.

c. The presence of large bubbles or a continuous

stream of bubbles indicates a leak.

d. Investigate potential leaks and rectify any

potential leaks in the low-pressure fuel system.

Check for leaks between the fuel tank and the

inlet of the fuel injection pump. If necessary,

replace the low-pressure fuel lines.

11. Remove Tooling (A) from the engine. Reconnect

the low-pressure lines.

12. Prime the fuel system. Refer to Operation and

Maintenance Manual, “Fuel System - Prime” for

the correct procedure.

i04676448

Finding Top Center Position for

No. 1 Piston

Table 2

Required Tools

Tool Part Number

Part Description

Qty

A

(1)

27610291

Barring Device Housing

1

27610289 Gear 1

(1)

This Tool is used in the aperture for the electric starting motor.

1. Rover the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install” for the correct

procedure.

2. Use Tooling (A) in order to rotate the crankshaft in

the normal direction of rotation.

3. Rotate the crankshaft in the normal direction of

rotation until the inlet valve of number 4 cylinder

has opened and the exhaust valve of the same

cylinder has not closed completely. The piston in

the number 1 cylinder should be at the top center

position.

i05241794

Fuel Injection Timing - Check

Table 3

Required Tools

Tool Part Number

Part Description

Qty

A

(1)

27610291

Barring Device Housing

1

27610289 Gear 1

B T400152

Camshaft Timing Pin

1

(1)

This Tool is used in the aperture for the electric starting motor.

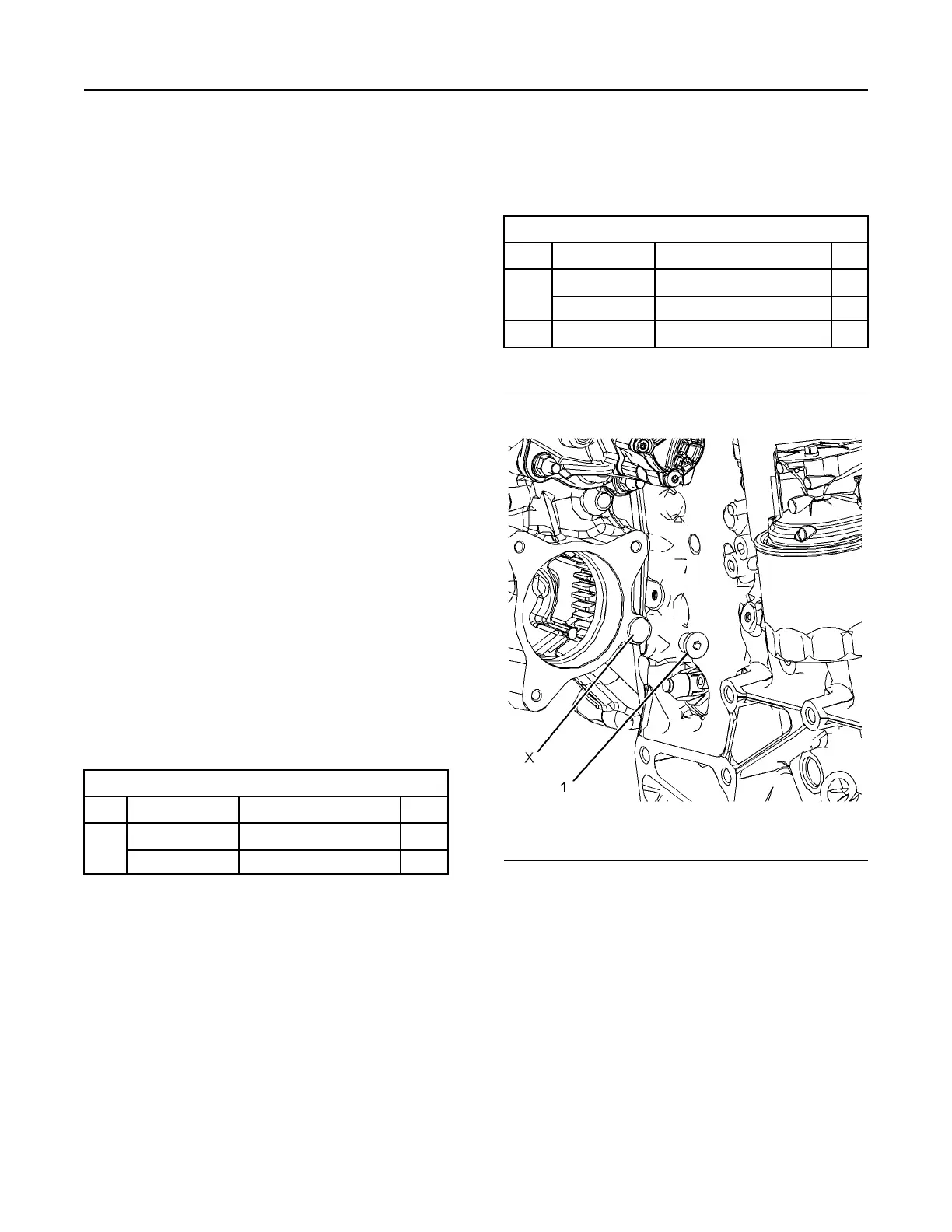

Illustration 48 g02862116

Typical example

1. If necessary, remove the accessory drive. Refer to

Disassembly and Assembly, “Accessory Drive -

Remove and Install” for the correct procedure.

Remove plug (1) from the engine. Use Tooling (A)

in order to rotate the crankshaft in the normal

direction of rotation.

2. Install Tooling (B) into Hole (X) in the engine. Use

Tooling (B) in order to locate the camshaft in the

correct position.

Note: Do not use excessive force to install Tooling

(B). Do not use Tooling (B) to hold the camshaft

during repairs.

52 UENR0623

Fuel System

Loading...

Loading...