Page 11

Keep each piston and connecting rad assembly

separate. each to each as marked.

The pistons are of light alloy, with fully floating

gudgeon ping, which work in the bush fitted to the

connecting rod small end. The gudgeon ping are

held in position by means of circlips.

The pistons are fitted with three compression

rings, and two oil control or scraper rings. The

top compression ring is a plain compression ring,

the second achrome plated compression ring and

the third is composed of four laminated rings.

(See fig. J .2).

To Remove Gudgeon Pins.

Remove circlips trom the piston. using long

nosed pliers.

Ta remave the gudgeon pins. warm the pistons

in liquid to a temperature of loooF.-120oF.

(38°-49°C.). The pins can then be pushed out.

The tourth and fifth rings are slotted scrapers.

Pistons are numbered from 1 to 4 commencing

with No. lat the front of the engine.

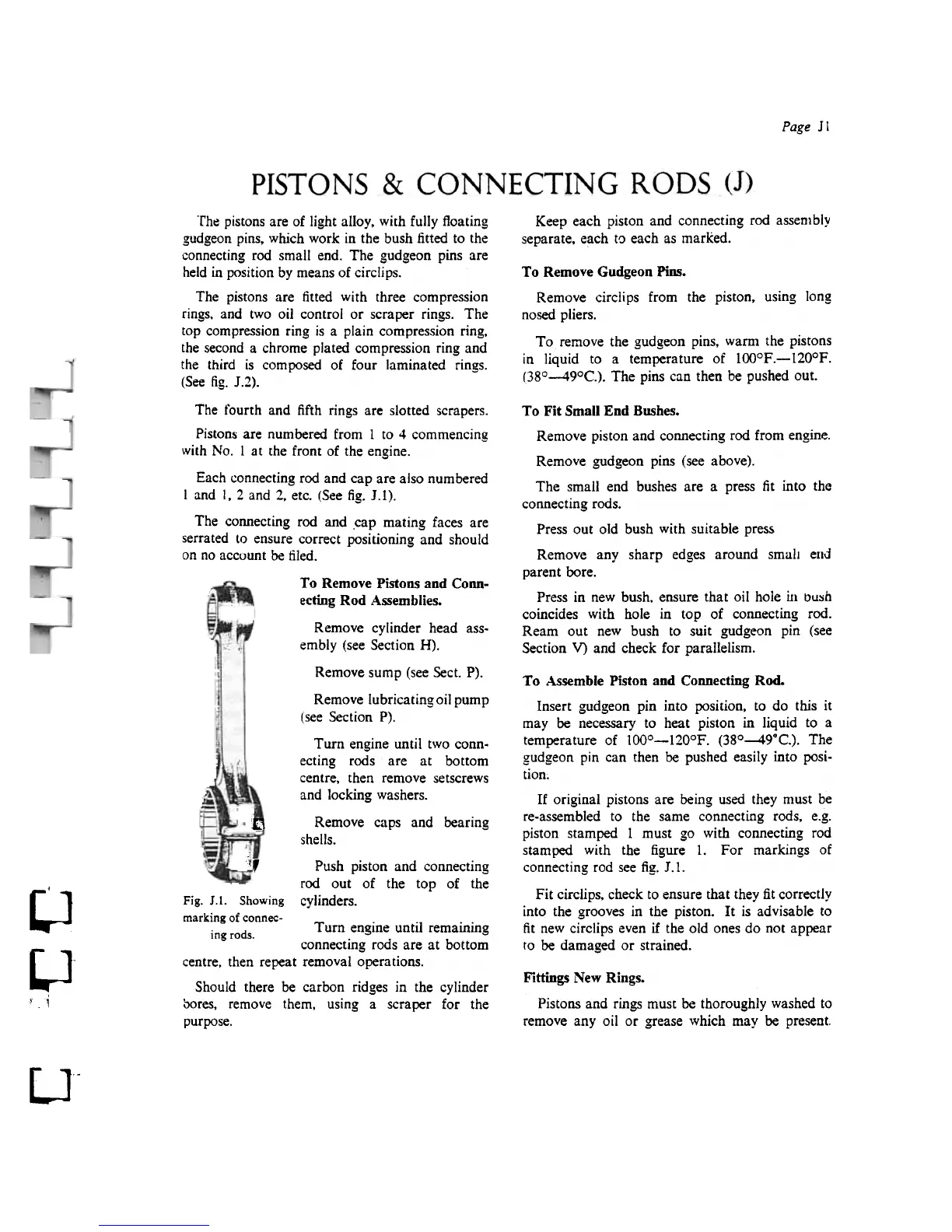

Each connecting rad and cap are also numbered

I and I, 2 and 2, etc. (See fig. J.1).

The connecting rad and .cap mating faces are

serrated la ensure correct positioning and should

on no account be filed.

To Fit Small End Bushes.

Remove piston and connecting rad from engine.

Remove gudgeon ping (see above).

The small end bushes are a press fit into the

connecting rods.

Press out aId bush with suitable press

Remove any sharp edges around smal! elld

parent bare.

Press in new bush. ensure that oiI hole Ul bu:ih

coincides with hole in top of connecting rad.

Ream out new bush to guit gudgeon pin (see

Section V) and check for parallelism.

To Remove Pistons and Conn-

ecting Rod Assemblies.

Remove cylinder head ass-

embly (see Section H).

Remove sump (see Sect. P).

Remove IubricatingoiJ pump

(see Section P).

Turn engine until two conn.

ecting roos are at bottom

centre. then re move setscrews

and locking washers.

Remove caps and hearing

shells.

l1

~,

Push piston and connecting

rad out of the top of the

cylinders.

To Assembie Piston and Connecting Rod.

Insert gudgeon pin into position. to do this it

may be necessary to heat piston in liquid to a

temperature of looo-120oF. (38°-49"C.). The

gudgeon pin can then be pushed easily into posi-

tion,

Tf original pistons are bejag used they must be

re-assembled to the same connecting rods. e.g.

piston stamped I must go with connecting rad

stamped with the figure 1. For markings of

connecting rad see fig. J .1.

Fit circiips. check to ensure that they fit correctly

into the grooves in the piston. Tt is advisable to

fit new circiips even if the oid ODes do not appear

to be damaged or strained.

u

Fig. J.1. Showing

marking of connec-

. d Turn engine until remaining

mg ro s.

connecting rods are at bottom

centre. then repeat removal operations.

Should there be carbon ridges in the cylinder

aDres. remove them. using a scraper for the

purpose.

~-

, . i

Fittings New Rings.

Pistons and rings must be thoroughly washed to

remove any oil or grease which may be present.

u-

Loading...

Loading...