~

.

Page S3

Fue/ lnjection System-continued

..,

-

..,

u

The upper, and helical edge of the annular

groove thus serves as a valve. The higher that

edge is in relation to the top of the plunger the

sooner the cut-oir and the less quantity of oil

supplied to the atomiser per stroke.

By varying the level of that edge the quantity

of oil supplied is controlled.

1

~

To alter that level, so that it uncovers the port

in the pump barrel to vary the quantity of fuel

delivered, the plunger is turned in its barre! by a

simple means to he described shortly.

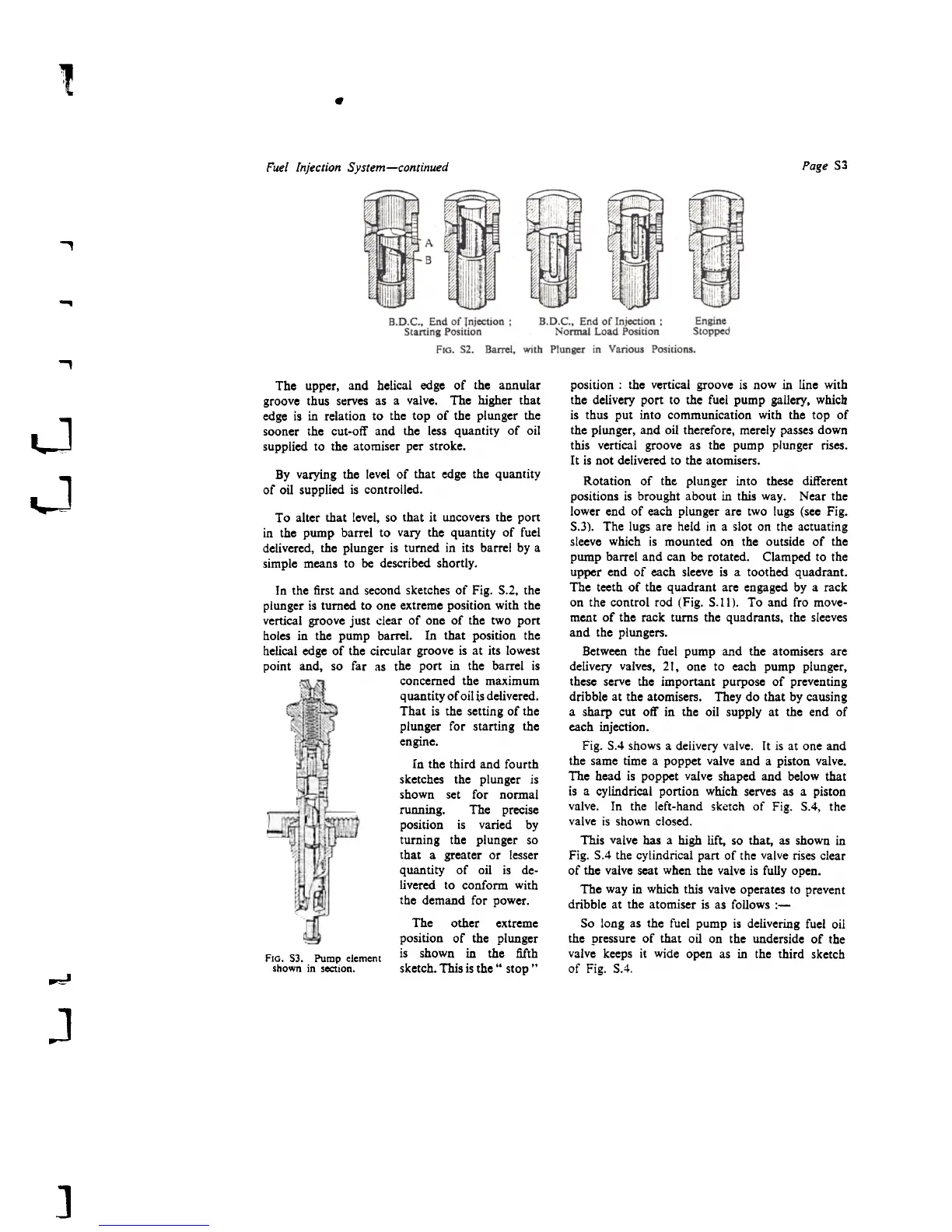

In the first and second sketches of Fig. S.2, the

plunger is tumed to one extreme position with the

vertical groove just clear of anc of the two port

holes in the pump barrel. In that position the

helical edge of the circular groove is at its lowest

point and, so far as the port in tbc barrel is

concemed the maximum

quantity of oil is delivered.

That is the setting of the

plunger for starting tbc

engine.

In the third and fourth

sketches the plunger is

shown set fot normal

running. The precise

position is varied by

tuming the plunger so

that a greater or lesser

quantity of oil is de-

livered to conform with

the demand for power.

The otber extreme

position of the plunger

FIG. SJ. Pump element is shown in the fifth

shown in section. sketch. This is the" stop .,

position : the vertical groove is now in line with

the delivery port to the fuel pump gallery, whicb

is thus put into communication with the top of

the plunger, and oil therefore, merely passes down

this vertical groove as the pump plunger rises.

It is not delivered to the atomisers.

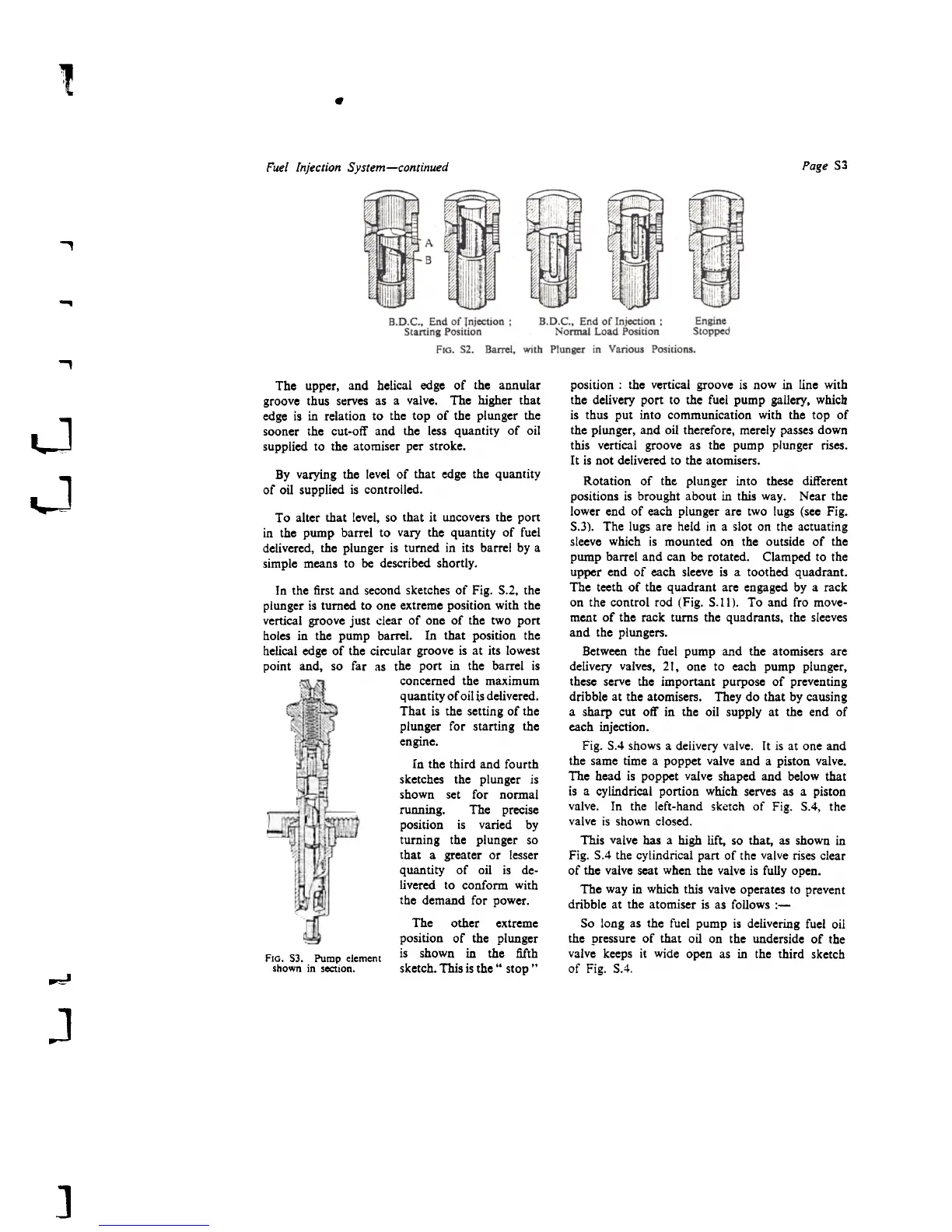

Rotation of the. plunger into these different

positions is brought about in this war. Near the

lower end of each plunger are two lugs (see Fig.

5.3). The lugs are held in a slot on the actuating

sleeve which is mounted on the outside of the

pump barrel and can be rotated. Clamped to the

upper end of each sleeve is a toothed quadrant.

The teeth of the quadrant are engaged by a rack

on the control rad (Fig. 5.11). To and fro move-

ment of the rack turns the quadrants, the sleeves

and the plungers.

Between the fuel pump and the atomisers are

delivery valves, 21, one to each pump plunger,

these serve the important purpose of preventing

dribble at the atomisers. They do that by causing

a sharp cut off in the oil supply at the end of

each injection.

Fig. 5.4 shows a delivery valve. It is at one and

the same time a poppet valve and a piston valve.

The head is poppet valve shaped and below that

is a cylindrical portion which serves as a piston

valve. In the left-hand sketch of Fig. 5.4, the

valve is shown closed.

This valve bas a high lift, so that, as shown in

Fig. 5.4 the cylindrical part of the valve rises clear

of the valve scat when the valve is fully open.

The war in which this valve operates to prevent

dribble at the atomiser is as follows :-

50 long as the fuel pump is delivering fuel oil

the pressure of that oil on the underside of the

valve keeps it wide open as in the third sketch

of Fig. 5.4.

~

J

]

Loading...

Loading...