.

.

~

-

Pag~ 57

Iel InjectÎon System-continued

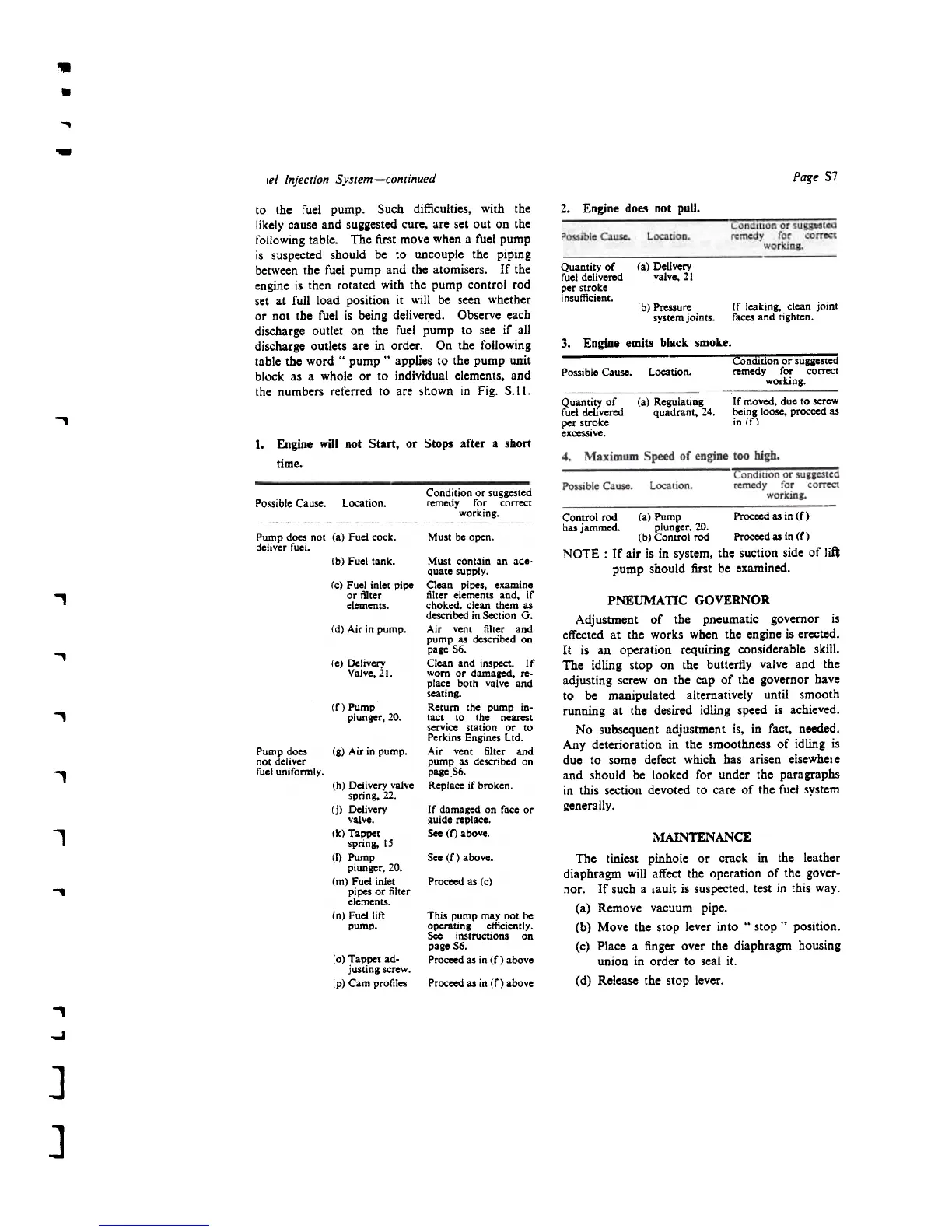

to the Cuet pump. Such difficulties, with the

likely cause and suggested cure, are set out on the

following ta bie. The fust move when a Cuel pump

is suspected should be to uncouple the piping

between the fuel pump and the atomisers. If the

engine is then rotated with the pump con trol rod

set at ruil load position it will be seen whether

or not the Cuel is being deliver.ed. Observe each

discharge outlet on the fuel pump to see if all

discharge outlets are in order. On the following

table the word .. pump " applies to the pump unit

block as a whole or to individual elements, and

the numbers reCerred 10 are shown in Fig. S.ll.

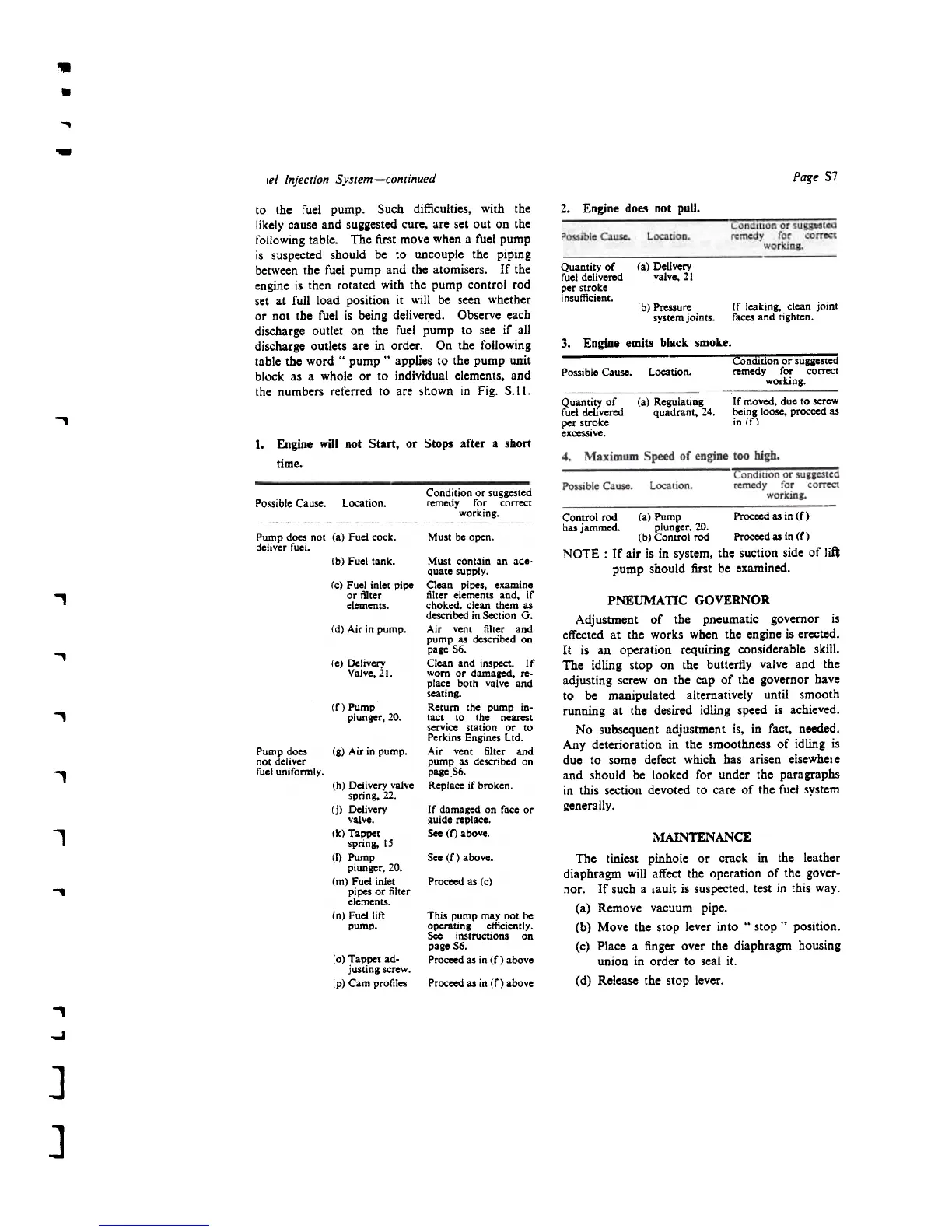

2. Engine does not pull.

Quantity of (a) Delivery

fuel delivered valve. 21

per stroke

insufficient.

~b) Pressure

system joints.

Ir leaking, clean joint

races and tighten.

3. Engine emits black smoke.

Condition or sugaested

Possible Cause. Location. remedy for correct

working.

Ir moved. duo to scrow

being 10050, proceed as

in (r)

Quantity of

Cue! delivered

per stroke

excessive.

Ca) Regulating

quadrant, 24.

..,

1. Engine will not Start, or Stops af ter a short

time.

Condition or suggcsted

remedy for correct

working.

Po~iblc Causc.

Location.

Control rad (a) Pump Proceed as in (r)

has jammcd. plunger. 20.

(b) Control rod Proceed as in (r)

NOTE : Ir air is in system, the suction side of lift

pump should fust be examined.

,

PNEUMAnc GOVERNOR

Adjustment of tbe pneumatic govemor is

etfected at the works when the engine is erected.

It is an operation requiring considerable skill.

Tbe idling stop on the buttertly valve and tbe

adjusting screw on the cap of the govemor have

to be manipulated altematively until smooth

running at the desired idling speed is achieved.

No subsequent adjustment is, in fact, needed.

Any deterioration in the smoothness of idling is

due to some defect which bas arisen elsewhele

and should he looked for under the paragraphs

in tbis section devoted to care of tbe fuel system

generally.

...,

,

,

Pump does not (a) Fuel cock. Must be open.

deliver fuel.

(b) Fuel tank. Must contain an ade-

quate supply.

(c) Fuel inlet pipe Clean pipes. examine

or filter filter elements and. if

elements. choked. clean them as

descnbed in Section G.

(d) Air in pump. Air vent filter and

pump as described on

page 56.

(e) Delivery Clean and inspect. Ir

Valve.21. worn or damaged. re-

place both valve and

seating.

(f) Pump Return the pump in-

plunger.20. tact to the nearest

service station or to

Perkins Engines ltd.

Pump does (g) Air in pump. Air vent filter and

not deliver pump as described on

fuel uniformly. page 56.

(h) Delivery valve Replace if broken.

spring, 22.

(j) Delivery If damaged on face or

valve. guide replace.

(k) Tappet See (f) above.

spring, 1 S

(1) Pump 5ee (f) above.

plunger. 20.

(m) Fuel inlet Proceed as (c)

pipes or filter

elements.

(n) Fuellift This pump may not he

pump. operating efficiently.

See instructions on

page 56.

Proceed as in (f) above

1

...

MAINTENANCE

Tbe tmiest pinhole or crack in the leather

diaphragm will affect the operation of the gover-

nor. If such a .ault is suspected. test in this way.

(a) Remove vacuüm pipe.

(b) Move the stop lever into " stop" position.

(c) Place a finger over the diaphragm housing

union in order to seal it.

(d) Release the stop lever.

:0) Tappet ad-

justing scrcw.

:p) Cam profiles Proceed as in (f) above

,

I

J

J

Loading...

Loading...