5 Troubleshooting

48

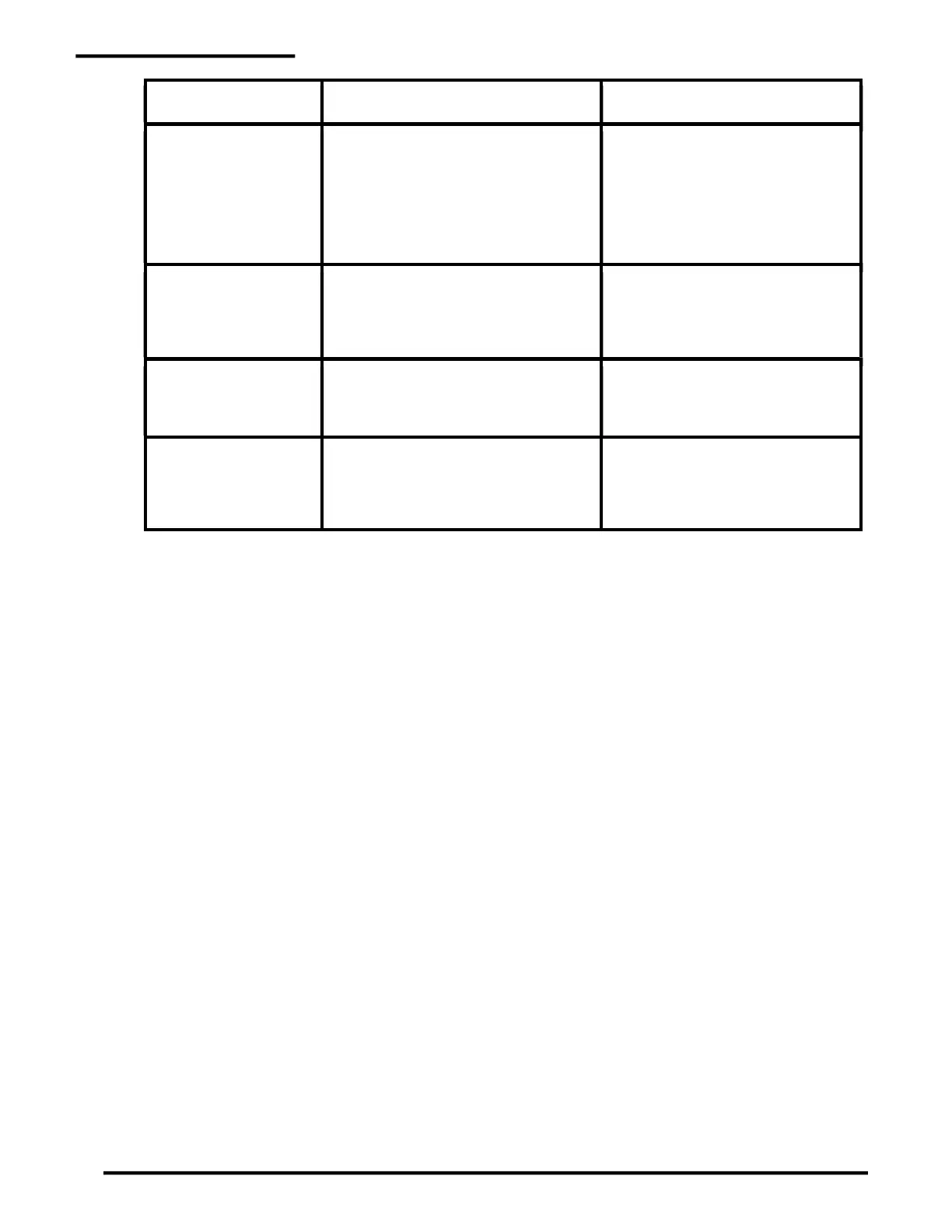

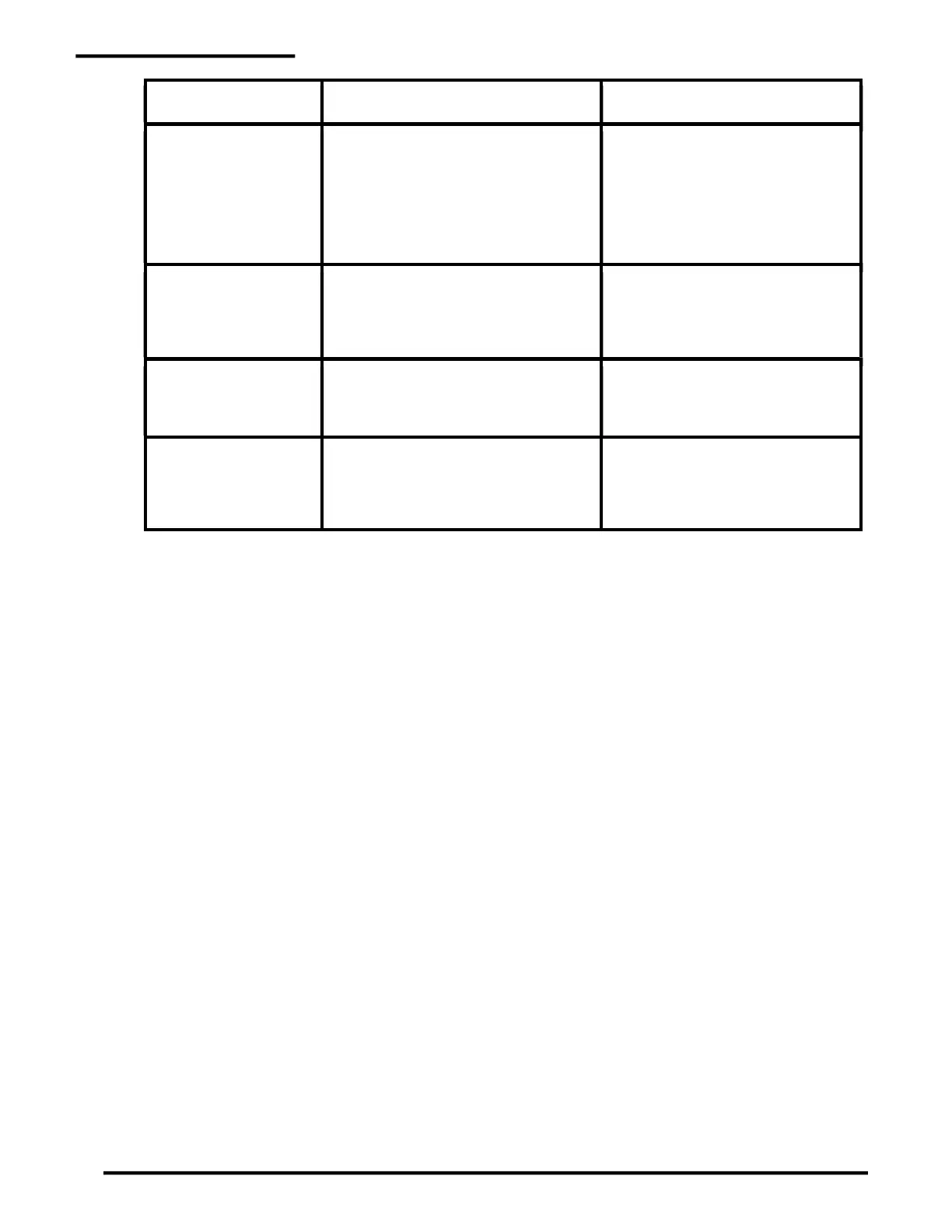

SYMPTOM POSSIBLE PROBLEM ACTION

No communication using

RS-232 or RS-485

Jumpers incorrect at J1 and J2 for

selecting RS-232/RS-485

Wiring incorrect or loose at terminal strip

T1

Port data type incorrect – Modbus RTU

or ASCII (for Palcom)

Baud rate of PAL-AT not correct

PAL-AT address not correct

Refer to PAL-AT Installation Manual,

section 2.61

Refer to section 2.9.4 in this manual

Refer to section 2.9.5 in this manual

Ethernet has link lights but

no communication

Ethernet client using wrong port to talk to

PAL-AT

PAL-AT address not correct

PAL-AT Ethernet addresses incorrect

Modbus TCP > port 502

Modbus RTU over TCP > port 1050

ASCII (Palcom) > port 1024

Refer to section 2.9.5 in this manual

No Ethernet link lights

Wrong speed / duplex setting

Port not active at connected switch

Bad cable

Change jumper to Auto Negotiate per

section 2.10.3.3

Verify connection at switch

Test / re-terminate structured cable

AT-ORC communications

problems

Wrong firmware in AT-ORC (AT-ORC

was originally used with older generation

PAL-AT)

Wrong firmware in PAL-AT (versions

1.10 & 1.12 must be upgraded to 1.14)

Send AT-ORC in to PermAlert for

firmware upgrade.

Upgrade PAL-AT firmware to 1.14

5.7 Restrictions & Limitations

For proper operation of the PAL-AT Leak Detection and Location system, the following restrictions and

limitations apply.

5.7.1 Sensor Cables

1. Sensor cables and jumper cables should not be installed in locations subject to frequent moisture

intrusion or wetness. The only exceptions are JMP-U and JPP jumper cable and TFH/TFH-Gold

sensor cables.

2. Electrical conduit for jumper cables must be sealed against moisture intrusion.

3. Cable connectors should be located in accessible areas. They must be electrically tested for

integrity and then encapsulated with shrink tubing and sealant.

The ability of PAL-AT to sense and locate leaks can be affected by the following occurrences:

1. An improperly installed connector can limit the ability of the system to see beyond it. Pinching or

cutting the cable can have the same effect.

2. Contamination such as dirt or mud filling a portion of the cable may make it insensitive to leaks in the

contaminated portion.

3. A large amount of wet cable will decrease the sensitivity and accuracy of the system beyond the wet

area. Several probes activated simultaneously have the same effect.

4. While the cables are made of durable and corrosion resistant materials, caution must be exercised in

cable handling to avoid excessive abrasion or damage. The damage may have a detrimental effect

on the operation of the system. Pulling the cable around sharp edges, or pulling cable through

secondary contained piping not properly designed to accept leak detection cables may cause abrasion

to the cable.

5. The sensor cables are corrosion resistant but if they are exposed to corrosive liquids, the contaminants

should be neutralized and the cables flushed. Untreated contamination may shorten the life of the

cable.

The following precautions must be observed for TFH and TFH-Gold hydrocarbon sensor cables.

1. The maximum burial depth is 20 ft [6 m].

Loading...

Loading...