Tires and Wheels Preventive Maintenance

– 180 –

PB1318 3/01 Model 330

Table 14 Comparing Hub-piloted and Ball-seat Wheels

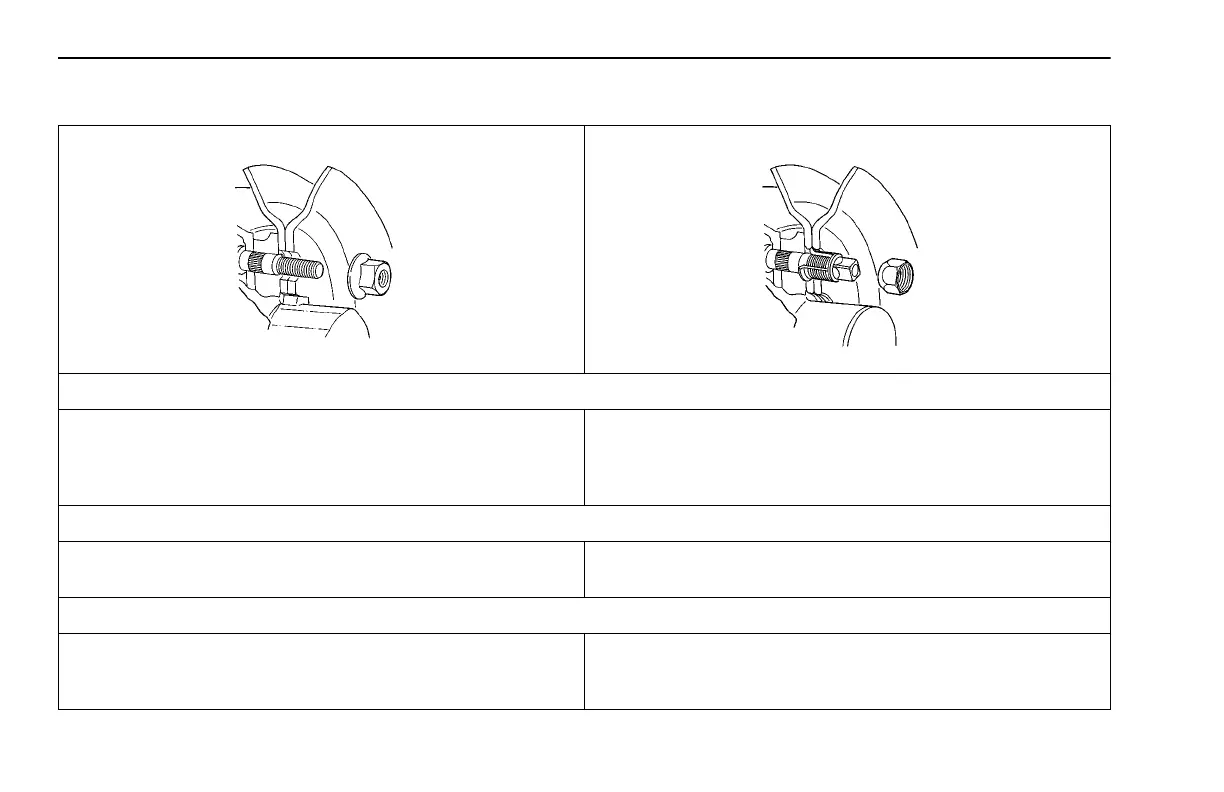

HUB–PILOTED MOUNT

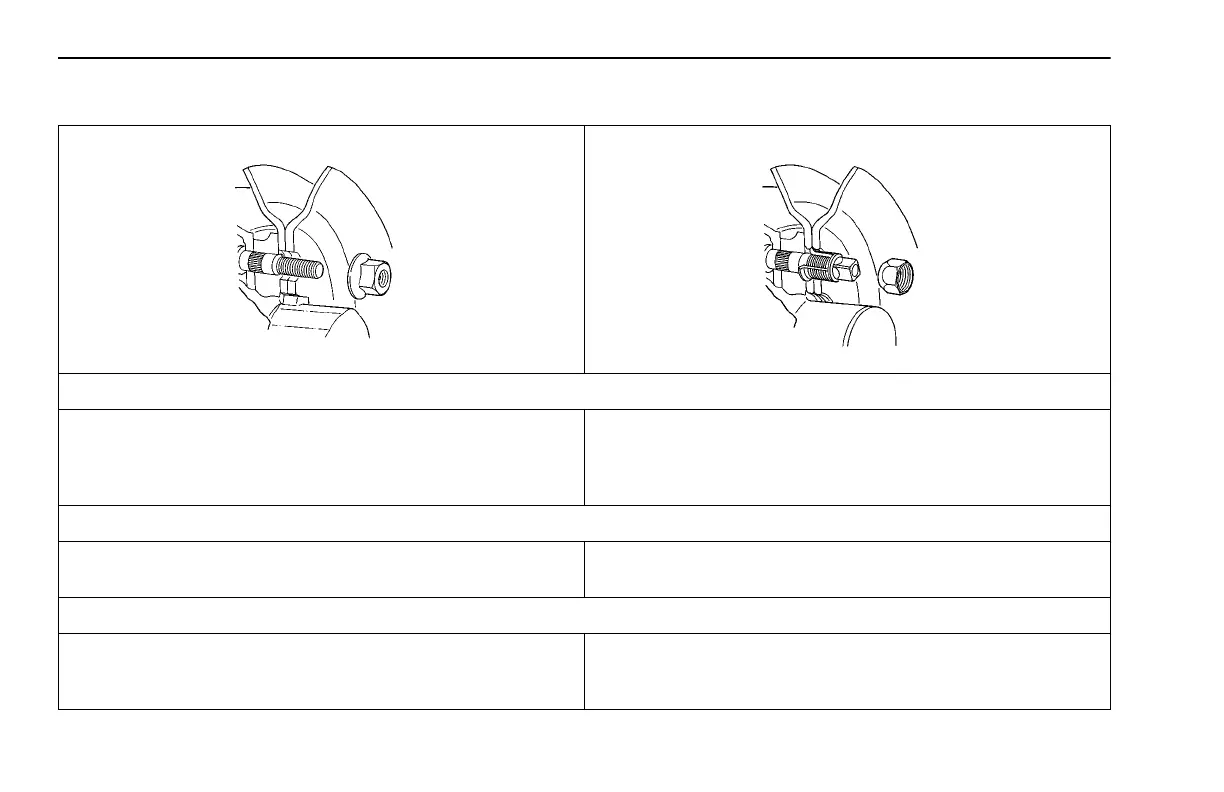

BALL–SEAT MOUNT

Hub, Drum, and Stud Assembly

Hub-piloted mountings use M22 x 1.5 metric threads (about 7/8 in.

diameter). The stud stands out at least 1.94 in. beyond the brake drum.

All studs are right-hand threads. Pilot bosses (machined surfaces) on

the hub, fit tightly to the wheel center bore.

Ball-seat (stud-piloted) mountings use 3/4x16 or 1-1/8x16 threads. The

dual mounting studs provide 1.30 in. –1.44 in. standout. Right-hand

and left-hand threads are required. Inner and outer wheel nuts center

the wheels by seating against wheel ball seats.

Wheels

Hub-piloted wheels have stud holes reamed straight through (no ball

seats). Center bore diameter is 8-21/32 in.

Ball-seat wheels have spherical chamfers machined on each stud hole.

Center bore diameter is 8-23/32 in.

Wheel Nuts

Hub-piloted wheel nuts have a hex body and a flange for clamping

against wheel face. Hex size is 1-5/16 in. (33 mm).

Ball-seat inner and outer wheel nuts mate with spherical chamfers on

wheels. The inner nut has 13/16 in. square end. The outer nut has a

1-1/2 in. hex.

00187

00203

Loading...

Loading...