44

Stitching off

15. Adjustment of needle threader

Requirement:

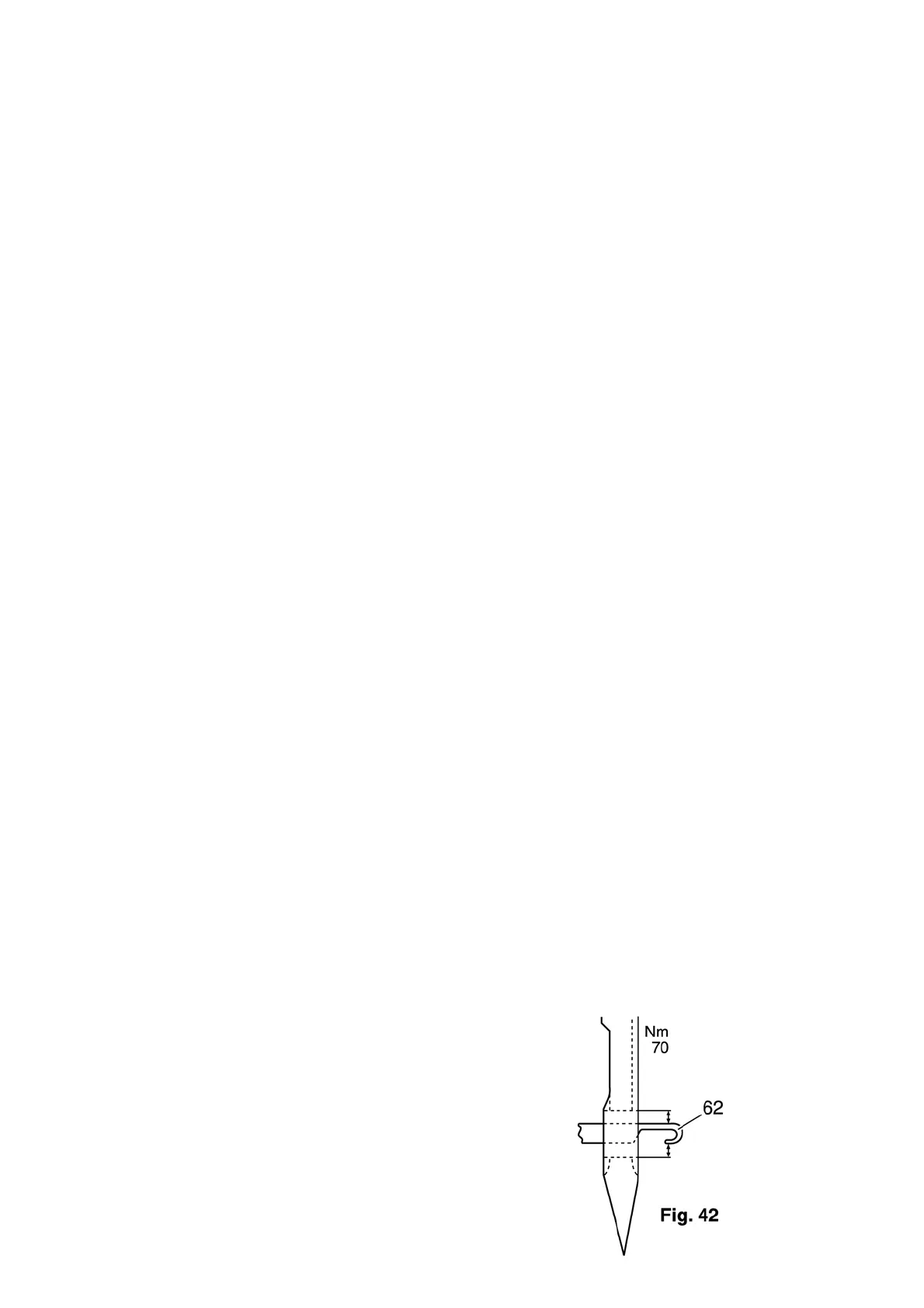

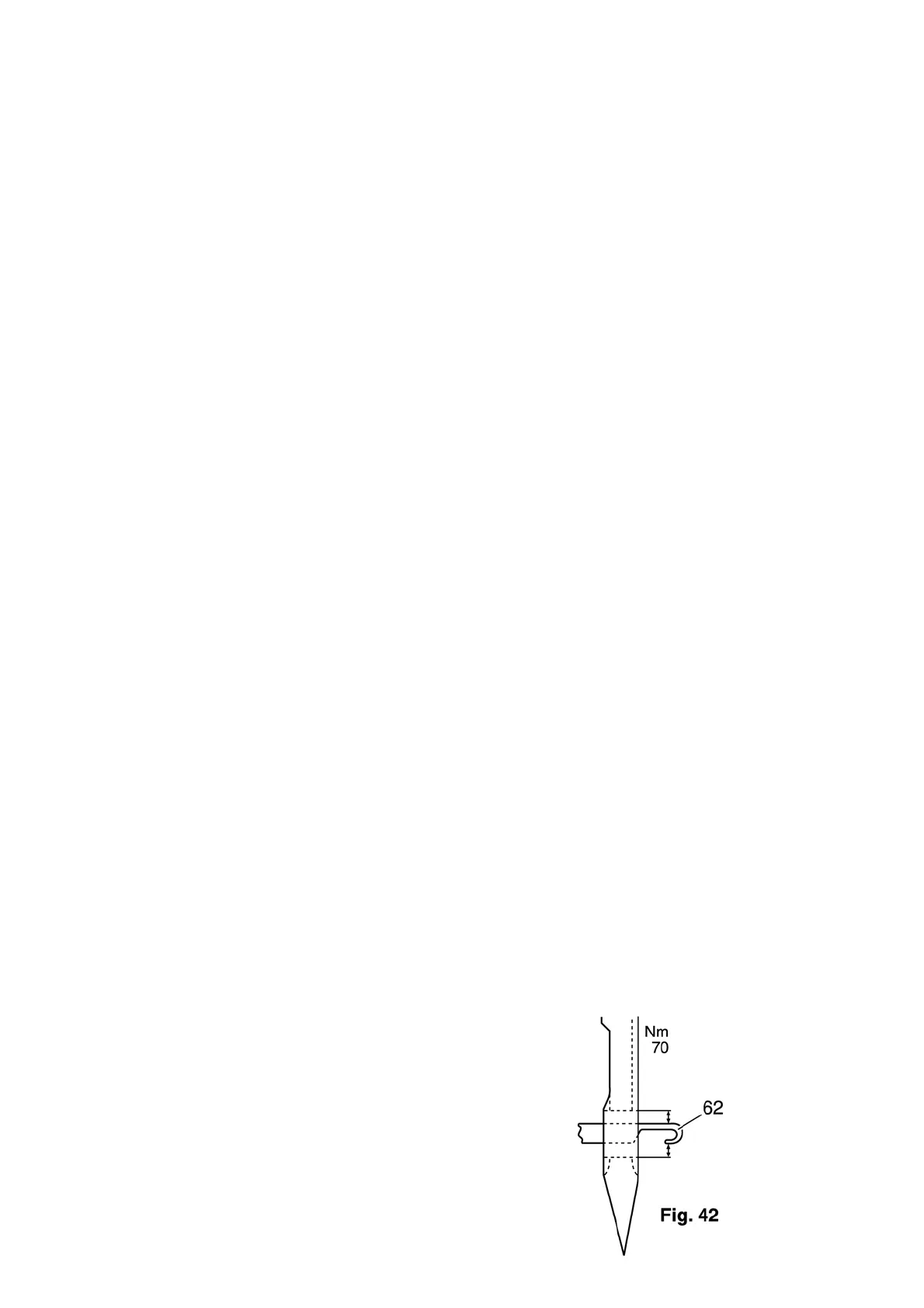

With the threader key pushed fully down, prong 62 must pass through in the center between the top and

bottom edge of the needle eye of a needle size Nm 70 (fig. 42).

Check:

● Insert a new needle system 130/705 H, size Nm 70.

● Switch on the machine (stitch program 01).

● Set the machine at top needle position by briefly pressing the foot control.

● Push threader key 63 fully down.

● Carry out a visual and functional test.

Height adjustment:

● Loosen the screw on the face cover and remove face cover.

● Press threader key 63 fully down and hold it in this position (fig. 44).

● Loosen allen screw 66 by only a 1/4 of a turn (fig. 43).

● Push the complete threader bar frame 67 either upwards or downwards until prong 62 has the same

clearance to the top and bottom edge of the needle eye (fig. 42).

● Tighten allen screw 66 in this position (fig. 43).

Cross-check 1:

● Using threader key 63, move the needle threader up and down.

Whilst doing so, carry out a visual check of the prong height.

● When the threader key is pushed down, pin 64 must pass completely through the diagonal guide slot

and rest on the upper end.

Lateral adjustment:

● Using threader key 63, place threader prong 62 at the front in the needle eye.

● Loosen screw 65 by only 1/8 of a turn (fig. 44).

● Push the threader bar frame either to the left or right until the prong is in the exact middle of the

needle eye.

● Tighten screw 65.

Cross-check 2:

● Activate threader key 63.

Whilst doing so, carry out a visual check of the lateral position

of the prong.

Loading...

Loading...